Exploit its versatile PA, faster TFM, innovative PCI, and efficient twin TFM/PCI to perform rapid and reliable inspections of welds and components.

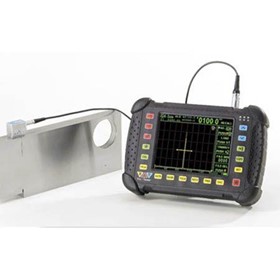

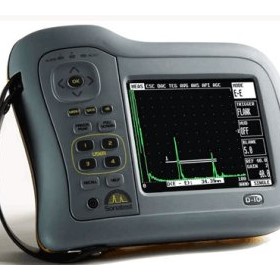

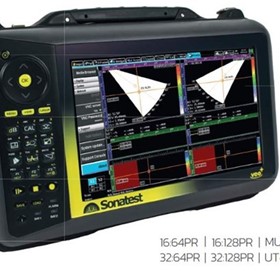

Be Ready for What’s Next: OmniScan X4 Flaw Detector

A portable yet powerful solution, the speed and versatility of the OmniScan™ X4 multitechnology series boosts your productivity while increasing confidence in your assessments. Exploit its advanced phased array capabilities, efficient total focusing method (TFM), and innovative phase coherence imaging (PCI) to detect and interpret challenging flaws and secure the integrity of your assets by identifying damage earlier.

Proven to Perform, Trusted to Deliver

Each OmniScan X4 unit is a complete multitechnology inspection toolbox, enabling you to exploit multiple ultrasonic testing techniques. Leverage its detection and measurement capabilities to accurately identify and evaluate the severity of damage before it becomes critical, protecting welds, components, and assets most susceptible to cracking or corrosion.

Assess with Certainty Using PCI

Eliminate doubt through phase coherence imaging’s capacity to detect and accentuate historically difficult-to-detect flaws, including hook cracks and stress corrosion cracking (SCC). Use PCI to clearly distinguish individual flaws in colonies of fine cracks and characterize them with certainty.

3x Faster TFM Acquisition Rate

Obtain crisp TFM imaging at up to three times faster* acquisition rates than the predecessor model (X3 64) thanks to the OmniScan X4 series’ improved processing power. Exploit the increased speed and 128-element capacity of the OmniScan X4 64:128PR unit to perform TFM inspections with extended focusing capabilities.

*Achieving this speed depends on the configuration and the use of sparse firing. Inquire for more details.

Gain Instant Insights and Eliminate Inefficiency

Twice the Confidence with Twin TFM and PCI

Exploit the individual attributes of PCI and TFM to thoroughly investigate the volume of welds from both sides simultaneously. Use two probes to scan the weld in one pass, displaying TFM and PCI results to compare, measure, and confirm your characterization of indications with efficiency and precision.

Engineered for Speed and Simplicity

Performing phased array, TOFD, TFM, and PCI is straightforward and intuitive on the OmniScan X4 series. Inspectors of any experience level can exploit these techniques with increased efficiency and more confidence utilizing the simple step-by-step scan plan and application presets.

Convenient Application Presets

Improve the learning curve and increase the reliability and consistency of inspections between operators with the OmniScan X4 application presets. Even low-level users and new users can produce an optimal PA or PCI configuration within minutes.

With options for corrosion and composite inspections, these preprogrammed parameters simplify scanning setups using HydroFORM™, FlexoFORM™, and RollerFORM™ scanners, and you can adjust the settings as needed.

Ease Complex Configurations

The OmniScan X4 scan plan’s intuitive step-by-step 3D graphics ease your inspection setups, from the most basic to the most complex.

When setting up your raster scan plan, the scan axes can be customed named and you can create a datum reference point relative to the asset. These real-world references as well as the true orientation correction, greatly ease the creation of an intuitive schematic representation of the inspection data for your report.

Applications

Choose the Right Model for Your Application

Each model of the OmniScan X4 series has the capability to drive probes with a certain number of elements, offering varying focusing capabilities for different materials and thicknesses. Here is an overview of the types of applications that the four models are most proficient at performing. Contact us or your Evident representative for more details.

| 16:64PR |

16:128PR |

32:128PR |

64:128PR |

|

Excels at the following applications:

- Corrosion monitoring

- Pipeline integrity

- Manual PA/TFM

- TOFD

- Small piping

|

Excellent mid-range model for:

- Thin weld ( 25 mm)

- Wind blade manufacturing

- Aerospace flaw detection

|

Enables high-productivity weld inspection including coarse-grained materials:

- Thick welds, up to ~75 mm

- Austenitic/CRA

- Occasional TFM

- Oil and gas

|

Higher-productivity weld inspection in thicker, coarse-grained materials:

- Very thick welds, ~100 mm (using a 64-element aperture to improve sizing accuracy)

- Austenitic/CRA

- Intensive TFM (HTHA)

- Advanced oil and gas and power gen

- FMC collection and application development

|

HTHA Inspection Solutions

OmniScan™ X4 Phased Array Flaw Detector with TFM and PCI

Detect and Define Smaller HTHA Cracks

Detecting HTHA early and reliably is so challenging that multiple inspection methods are often used in conjunction to maximize the probability of detection. Time-of-flight diffraction (TOFD), along with focused phased array (PA) and the total focusing method (TFM), especially using Dual Linear Array™ (DLA) probes, have shown to be particularly effective inspection techniques for this application.

OmniScan™ X4 flaw detector fully supports these methods, as well as innovative phase coherence imaging (PCI), which enhances small flaws and crack tips. OmniScan X4 instruments also offer a variety of onboard software tools to ease your setup and analysis workflow.

- Integrated DLA probe configuration and scanner configuration

- High-resolution TFM images (up to 1024 × 1024 points)

- Software tools to optimize the TFM inspection process, from setup to analysis (scan plan with AIM model, automatic TCG, sparse firing, soft gain and palette slider, live TFM envelope and image filters, gates, and alarms)

- 64-element TFM aperture and 128-element extended TFM aperture (OmniScan X4 64:128PR model)

- Phase coherence imaging to enhance small defects and crack tips (all OmniScan X4 units)

- Acquire up to 8 TOFD and phased array groups simultaneously for efficient screening

- Acquire and display up to 4 TFM and PCI groups at once

- Plane wave imaging (PWI) available with TFM and PCI (using the OmniScan X4 unit with linear array probes)

Weld Solutions

OmniScan™ X4 Phased Array Flaw Detector

Get the Most Out of Your Inspection

The Omniscan X4 flaw detector is a comprehensive multitechnology toolbox, equipped with setup, imaging, and analysis to tools that make weld inspection easier

- Do your complete setup using the intuitive onboard scan plan without having to use a PC

- Improved fast calibration

- Enhanced image resolution and geometrically correct flaw representation with multigroup total focusing method (TFM) imaging and phase coherence imaging (PCI)

- Twin TFM/PCI images the volume of welds from both sides, using two probes, displaying TFM and PCI data simultaneously on the display

- Standard PR configuration enables the use of larger apertures on dual array probes (up to 128-element extended TFM aperture with the 64:128PR model)

The OmniScan X4 flaw detector excels at a broad range of weld inspection applications, including:

- In-service and construction welding

- Pressure vessels

- Process pipes

- Boiler tubes

- Pipeline

- Wind tower

- Structural construction

- Corrosion-resistant alloys and cladded materials (austenitic, nickel, and other coarse-grained materials)

Specifications:

|

|

|

|

335 mm × 221 mm × 151 mm (13.2 in. × 8.7 in. × 5.9 in.)

|

|

|

5.7 kg (with 1 battery) for model 16:64PR

5.9 kg (with 1 battery) for models 16:128PR, 32:128PR, and 64:128PR

|

|

|

1 TB internal SSD storage. Maximum 25 GB individual file size. Storage extensible using external USB drive

|

|

|

SDHC and SDXC cards, or most standard USB storage devices

|

|

|

Wi-Fi® 6E and Bluetooth® 5.3 onboard

|

|

|

1 PA connector, 2x UT channels (2 P/R connectors each)

|

Available Configurations and Groups

|

OmniScan X4A – 64 :128PR : 8 groups

OmniScan X4A – 32 :128PR : 8 groups

OmniScan X4A – 16 :128PR: 8 groups

OmniScan X4B – 16 :64PR: 2 groups (PA, UT, or TFM) or a specific configuration of 2 PA groups + 1 TOFD

|

|

|

Drop-tested according to MIL-STD-810G

|

Ingress Protection Rating

|

IP65 Certified (completely protected against dust and water jets from all directions (6.3mm nozzle))

|

|

|

269 mm (10.6 in.) TFT LCD with resistive touch screen, 1280 × 768 pixels

|

|

|

2 hot-swappable Lithium-ion batteries included, 87 Wh each

|

|

|

Minimum of 5 hours (using ISO18563 standard setup parameters)

|

|

|

−10 to 45 °C (14 °F to 113 °F)

|

|

|

−20 °C to 60 °C (−4 °F to 140 °F) (with battery inside)

−20 °C to 70 °C (−4 °F to 158 °F) (with no battery inside)

|

|

|

|

|

2x USB 3.1, 1x video out (HDMI), 1x SDHC memory card slot, 1x communication (Ethernet)

|

|

|

2-axis encoder line (quadrature or clock/direction)

|

Digital Inputs and Outputs

|

4 digital inputs (TTL), 4 digital outputs (TTL) including one reserved for acquisition on/off

|

|

|

18 VDC, circular 2.5 mm diameter connector, center-positive

|

General Ultrasonic Specifications

|

Effective Digitizing Frequency

|

Up to 100 MHz; User-adjustable compression factor

|

Maximum Pulse Repetition Rate (PRF)

|

Up to 20 kHz; Actual maximum PRF is often limited by physics

(the time of flight required to obtain the ultrasonic signals)

|

Maximum Number of A-Scan Data Points

|

|

|

|

|

|

|

RF, full wave, half wave+, half wave−

|

|

|

Smoothing (adjusted to the probe frequency range)

|

|

|

PA channel: selection of band-pass filters, high-pass filters, and averaging

UT channel: selection of low-pass filters, band-pass filters, high-pass filters, and averaging

|

Time-Corrected Gain (TCG)

|

PA: 40 dB per step of min. 0.1 dB

UT: 100 dB per step of min. 0.1 dB

Maximum slope of 40 dB/10 ns

|

Supported Beam Types (Groups)

|

Selection of phased array ultrasonics (PAUT) beam types (linear, sectorial, and compound), single ultrasonic beam (UT), time-of-flight-diffraction ultrasonics (TOFD), total focusing method (TFM), phase coherence imaging (PCI), full matrix capture (FMC), and plane wave imaging (PWI)

|

Raw Full Matrix Capture (FMC) Data Collection

|

Available only with model 64:128PR when using the NDT Device API or the OmniScan Black Box onboard application used with external acquisition software

|

|

|

|

|

|

|

|

|

Calibration Certification

|

|

|

|

|

Adjustable from 30 ns to 1000 ns; resolution of 5 ns (half period of bipolar pulse or duration of negative pulse)

|

Adjustable from 30 ns to 1,000 ns; resolution of 2.5 ns

|

|

|

Bipolar negative-positive square pulse

|

|

|

|

|

0 dB to 80 dB; maximum input signal 900 mVp-p (full-screen height).

|

0 dB to 120 dB; maximum input signal 30 Vp-p (full-screen height)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum Number of Receiving Channels

|

|

|

|

|

|

|

1024 maximum total (512 maximum per group)

|

FMC / TFM / PCI / PWI Specifications

|

|

|

|

|

|

|

Maximum Extended Aperture (FMC)

|

|

|

|

|

|

|

|

|

|

|

Maximum TFM or PCI Groups

|

|

|

|

|

|

|

Yes – Actual Hilbert Transform

|

|

|

Up to 1024 × 1024 (1M points) for each TFM or PCI wave set

|

FMC Supported Wave Sets (TFM or PCI Modes)

|

Pulse-Echo: L-L, T-T, and TT-TT

Self-Tandem: TT-T, TT-TTT, LL-L, LT-T, TL-T, TT-L, and TL-L

|

PWI Supported Wave Sets (TFM or PCI Modes)

|

|

Read less...

To contact Evident Australia about Ultrasonic Flaw Detector 3x Faster TFM Acquisition Rate | OmniScan X4 use Get a quote.

-280x280-state_7.jpg)