Scan for minimal thickness areas at a 2 times faster display update rate. Tackle multiple thickness applications with full line of dual and single element transducers.

Faster Thickness Results

Streamline your ultrasonic thickness inspection process with one fast, connected, and reliable handheld gauge. The 39DL PLUS™ gauge works as a precision or corrosion thickness gauge for demanding applications.

With world-class ultrasonic capability, fast scanning speeds up to a 60 Hz update rate, and fully integrated wireless connectivity, our flagship handheld thickness gauge delivers results you can trust in a seamless workflow.

- Connected: Integrated Wi-Fi®, Bluetooth®, USB, RS-232, and a removable microSD card*

- Fast: Scan for minimal thickness areas at a 2 times faster display update rate**

- Versatile: Tackle multiple thickness applications with our full line of dual and single element transducers

*Wi-Fi® and Bluetooth® are pending certification in some regions. Contact your local Evident representative for details on their availability.

**Up to 60 Hz versus 30 Hz on the predecessor model and comparable handheld thickness gauges.

Affordable Part Scanning

With breakthrough scanning speeds, the 39DL PLUS instrument offers an industry-leading* 60 Hz update rate for handheld thickness gauges.

- Works as an affordable alternative for inspection codes that require a 60 Hz display update rate for scanning; get the scanning speed of a flaw detector with the ease of use of a thickness gauge

- Find thin spots more easily when scanning for minimal thickness areas on pipes and other assets affected by corrosion

*As of June 2024.

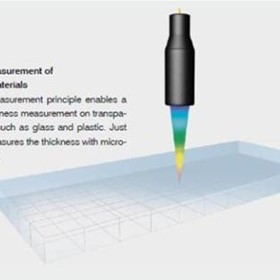

One Thickness Gauge for Multiple Applications

Take advantage of powerful measurement features and a suite of application-specific software options for your current and future requirements.

- Wide thickness range: 0.08 mm (0.003 in.) to 635 mm (25 in.) depending on material and transducer selection

- Corrosion thickness gauging with dual element transducers

- High Resolution software option of 0.001 mm or 0.0001 in. with single element transducers from 2.25 MHz to 30 MHz

- THRU-COAT™ technology and echo-to-echo measurements to measure through painted and coated surfaces

- Internal Oxide/Scale software option for boiler tube and internal oxide measurements

- Multilayer software option to measure up to four layers simultaneously

- High Penetration software option for attenuating materials such as fiberglass, rubber, and thick castings

- Standard resolution: 0.01 mm or 0.001 in. for all transducers

- Thickness, velocity, and time-of-flight measurements

- Differential mode and reduction rate mode to track thickness variation and its percentage from a preset value

- Time-based B-scan mode: 10,000 reviewable readings per scan

- High Dynamic Gain technology with digital filters optimizes the starting gain setting based on calibration

- V-Path Builder for custom V-path compensation in corrosion applications

- Designed for EN15317 compliance

- Compatible with all probes and accessories supported on the predecessor model

Trusted Ultrasonic Technology

The 39DL PLUS™ gauge builds on proven performance. Confidently perform your work with industry standard technology for ultrasonic thickness testing.

- Accurate, reproducible measurements from exceptional signal quality, stable waveforms, and optimized algorithms

- World-class ultrasonics developed by professionals with 35+ years of nondestructive testing (NDT) experience

Built to Last in Any Environment

Your thickness gauge needs to keep working despite shocks, drops, and rough handling, and the 39DL PLUS instrument is up to the challenge.

- Rugged: Designed for IP67 for protection against dust and water

- Explosive atmosphere, shock, and vibration tested using MIL-STD-810H

- Wide operating temperature range: –10 °C to 50 °C (14 °F to 122 °F)

- Protective rubber boot with gauge stand

Easy to Carry, Easy to Use

Designed with the operator in mind, the 39DL PLUS handheld gauge is comfortable to carry and use in the field or on the production floor.

- Ergonomic keypad: operate with the left or right hand for quick access to all functions

- Lightweight handheld design: Weighs only 0.83 kg (1.83 lb)

- Built-in data logger: Easily collect thickness readings and waveform data

- Efficient inspections: Default and custom setups for dual and single element transducers

- Secure access control: Lock instrument features with password-protected functions

- Excellent clarity: Color transflective VGA display with indoor and outdoor color settings

- See work on a larger screen: VGA output to connect the gauge to a computer or monitor

Workflow

Save Time with a Digital Inspection Workflow

Integrated Wi-Fi® and Bluetooth® capabilities on the 39DL PLUS™ thickness gauge enable a seamless inspection workflow for Industry 4.0.

- Wirelessly connect to the Link Plus iOS app, Link-Wedge software, or the Inspection Project Manager (IPM) app to effortlessly share results

- Use GageView™ software for the flexibility to review data with a wired connection

Powerful Workflow Management Tools

The Inspection Project Manager (IPM) is a cloud-based web and mobile app offering a digital inspection workflow that improves efficiency and data integrity.

- Use the iOS or Android mobile app with or without an internet connection to efficiently execute inspection tasks

- Collect inspection data and digitally sign off on inspection tasks in an intuitive interface

- The digital report automatically updates throughout your inspection

Send Thickness Data to Your Mobile Phone or Tablet

Use the Link Plus iOS app and Bluetooth® to send thickness data to your phone or tablet.

- From your mobile device, share thickness data over text message or email, or save the data as a text file for easy import to a spreadsheet

- You can also send data to compatible third-party mobile applications

Easily Populate Your Thickness Data into Data Entry Programs

Use the optional Link-Wedge software and Bluetooth® to send data from your gauge to an active Windows software application. The software can populate data into almost any Windows-based data entry program.

Remote Control and Integration

The 39DL PLUS gauge offers the potential for remote control and integration, enabling convenient control of the gauge from a distance in innovative applications. To learn more about these capabilities, reach out to your local Evident sales representative.

Confidence in Your Thickness Data

Built-In Data Logger

Improve productivity and data traceability with the full-featured, built-in data logger on the 39DL PLUS gauge. The bidirectional alphanumeric data logger is designed to easily collect and transfer thickness readings and waveform data.

Log data

- Internal memory of 792,832 thickness readings or 20,000 waveforms with thickness readings

- 32-character file name

- 9 file formats: incremental, sequential, sequential with custom point, 2D grid, 2D grid with custom point, 3D grid, 3D custom, boiler, and manual

- 20-character ID# (thickness measurement location or TML#)

- Store up to 4 notes per ID#

- Store notes at one or more ID#s

Analyze data

- Onboard statistical report

- Assess readings at a glance: Onboard DB Grid View with three programmable colors set to specific thickness values

Transfer data

- Wirelessly share data: integrated Wi-Fi® and Bluetooth®

- Wired data transfer: USB and RS-232 communication ports

- Two-way transfer of single and dual element transducer setups

- Copy files between internal/external microSD™ memory cards; directly export internal files to a microSD card in an Excel-compatible CSV format

PC Software

The GageView™ interface program, a Windows-based application, collects, creates, prints, and manages data from the 39DL PLUS gauge. The software communicates with the gauge using the USB and RS-232 ports, and it can read and write to a microSD memory card.

- Create datasets and surveys

- Edit stored data

- View dataset and survey files, including thickness readings, gauge setup values, and transducer setup values

- Download and upload thickness surveys to and from the gauge

- Export surveys to spreadsheets and other programs

- Collect snapshot screens

- Print reports such as thickness, setup table, statistics, and color grid

- Upgrade the operating software

- Download and upload single and dual element transducer setup files

- B-scan review

Specifications:

|

|

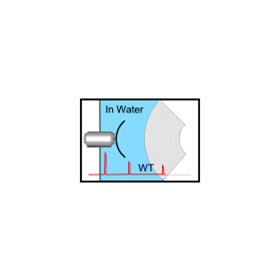

Dual element transducer measurement mode

|

Time interval from a precision delay after the excitation pulse to the first echo

|

|

|

Measurement of true metal and coating thicknesses with a single back-wall echo (with D7906-SM and D7908 transducers)

|

|

|

Time interval between two successive back-wall echoes to eliminate paint or coating thickness

|

Single element transducer measurement modes

|

Mode 1: Time interval between the excitation pulse and the first back-wall echo

Mode 2: Time interval between the delay line echo and the first back-wall echo (with delay or immersion transducers)

Mode 3: Time interval between successive back-wall echoes following the first interface echo after the excitation pulse (with delay line or immersion transducers)

Oxide: optional

Multilayer mode: optional

|

|

|

0.08 mm to 635 mm (0.003 in. to 25 in.) depending on material, transducer surface conditions, temperature, and selected configuration

|

|

|

0.508 mm/μs to 13.998 mm/μs (0.02 in./μs to 0.551 in./μs)

|

|

|

Low: 0.1 mm (0.01 in.)

Standard: 0.01 mm (0.001 in.)

High Resolution (optional): 0.001 mm (0.0001 in.)

|

Transducer frequency range

|

Standard: 2.0 MHz to 30 MHz (-3 dB)

High Penetration (optional): 0.50 MHz to 30 MHz (-3 dB)

|

|

|

Operating temperature range

|

-10 °C to 50 °C (14 °F to 122 °F)

|

|

|

Sealed, color-coded keypad with tactile and audible feedback

|

|

|

Impact-resistant and water-resistant, gasketed case with sealed connectors. Designed for IP67.

|

|

|

Overall: 125 mm × 211 mm × 46 mm (4.92 in. × 8.31 in. × 1.82 in.)

|

|

|

|

|

|

AC/DC adapter, 24 V; lithium-ion battery 23.760 Wh; or 4 AA auxiliary batteries

|

Battery life, lithium-ion

|

Operating time: typically 8 hours

Fast charge: 2 to 3 hours

|

|

|

|

|

|

Testing using MIL-STD-810H, Section 511.7, Procedure I

|

|

|

Color transflective VGA display

|

Liquid crystal display, display area 56.16 mm x 74.88 mm (2.2 in. x 2.95 in.)

|

|

|

Full wave, RF, half-wave positive, or half-wave negative

|

|

|

|

|

|

|

|

|

|

Maximum capacity: 32 GB external microSD memory card

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The 39DL PLUS identifies, stores, recalls, clears, and transmits thickness readings, waveform images, and gauge configuration information through the standard RS-232 serial port or USB port

|

|

|

792,832 thickness measurements or 20,000 waveforms with thickness measurements

|

File names, IDs, and comments

|

32-character file names and 20-character alphanumeric location codes with four comments per location

|

|

|

Nine standard or custom application-specific file structures

|

|

|

On-gauge reporting of summary with statistics, Min./Max. with locations, Min. review, file comparison, and alarm report

|

Standard Package

39DL PLUS digital ultrasonic thickness gauge, AC or battery, 50 Hz to 60 Hz. Kits available with standard dual element transducers.*

- Charger/AC adapter (100 VAC, 115 VAC, 230 VAC)

- Internal data logger

- GageView interface program

- Test block* and couplant

- USB cable

- Rubber protective boot with gauge stand and neck strap

- User's manual

- Two-year limited warranty

Measurement features: THRU-COAT, Thru-Paint Echo-to-Echo, EMAT compatibility, Min./Max. mode, two alarm modes, differential mode, B-scan, Application Auto-Recall, temperature compensation, Average/Min. mode

*In the EMEA region, transducers are not included and must be purchased separately.

Software Options

39DLP-OXIDE (Q1470008): Code-activated Internal Oxide measurement software

39DLP-HR (Q1470006): Code-activated High Resolution measurement software

39DLP-MM (Q1470007): Code-activated Multilayer measurement software

39DLP-HP (Q1470005): Code-activated High Penetration (low frequency) measurement software

39DLP-EBSCAN (Q1470004): Encoded B-scan software

Optional Accessories

1/2XA/E110 (U8767104): Filter adapter for E110-SB EMAT transducer

38-9F6 (U8840167): RS-232 cable

38-C-USB-IP67 (U8800998): USB cable for IP67 sealed operation

38DLP/RFS (U8780288): Foot switch, factory installed

HPV/C (U8780124): Digital caliper for thickness input for velocity measurements

38DLP-V-CC (U8840172): Cable for digital caliper

EPLTC-C-VGA-6 (U8840035): VGA output cable

MICROSD-ADP-2GB (U8779307): 2 GB external microSD memory card (gauge can use up to a 32 GB microSD card)

BSCAN-ENC (U8779522): Encoded B-scan buggy

38DL-ENC-CBC-10 (U8840168): 10 ft encoder cable

Read less...

To contact Evident Australia about Thickness Gauge 0.08 mm to 635 mm | 39DL PLUS use Get a quote.