The difference to other welding methods is that the filler rod that serves as the welding electrode in MMA welding shortens continuously as the welding progresses. In TIG and MIG/MAG welding, the distance of the torch from the work piece must remain constant at all times. In MMA welding, however, the electrode holder must continuously be brought toward the work piece to keep the distance between the electrode and the molten weld constant. This presents special challenges for MMA welding.

APPLICATIONS

MMA welding can be used under almost any conditions, and therefore it is a rather universal method in the welding industry. It is commonly used in installation worksites were good reachability is required of welding machines and where work is often done in outdoor environments.

MMA welding is a common welding method for example in welding power plant pipelines and in other pipe welding sites. It is also a welding method favoured by hobbyists and small repair shops. It can also be applied in underwater welding, where fillers designed particularly for underwater environments are used.

EQUIPMENT

MMA welding requires a power supply, a ground cable and a welding cable equipped with the electrode holder. There is no shielding gas, as the welding electrode is coated with a material that produces shielding gas and slag over the molten weld pool. Many TIG welding machines are also suitable for MMA welding.

Today’s small inverter power sources further increase mobility and reach ability. The power supply can, for example, be connected to a generator with long input cables, taking the welding machine next to the work piece. The smallest power sources currently weigh only 5 kg (10 lbs).

MMA welding is rather popular in hobbyist use as the only required parts are the power source and the filler material rods. No shielding gas is required, and the devices usually operate with the current obtained from a regular residential power outlet.

Browse Kemppi MMA welding equipment.

ELECTRODES

A welding electrode is a fixed-length, straight welding wire coated with a filler material. The welding electrode as a fixing head with which it is attached to the electrode holder. The other end of the electrode has the ignition head with which the work piece is stuck to ignite the arc. The quality or trade name of the electrode is indicated near the fixing head in the coating. Usually also the AWS class ID is included.

The diameter of a welding electrode refers to the diameter of the metal rod inside the electrode. The purpose of the coating on the surface of the metal rod is to protect the welding event from the effects of the surrounding air, to produce slag to support the weld and to make the creation of the arc easier.

TECHNIQUE

Before welding, it is recommended that one check the condition of the welding power source, the cables, electrode holder and the grounding clamp. If the power source has a control panel and remote control, their functionality should also be reviewed. The quality and strength of the welding electrodes must be checked and they must match the work piece. The coating on the electrode must be intact.

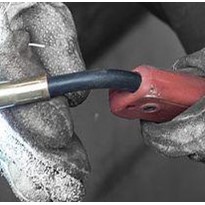

The welding is started by sharply striking the bottom of the groove with the welding electrode. After this, move the welding electrode back to the beginning without stretching the arc, and move the electrode easily while monitoring the width of the molten weld pool. Move the welding electrode with the handle pointing forward. The boundary of the slag formed is visible after the molten weld. It must be behind the molten weld. The distance of the slag boundary from the molten weld can be adjusted with the welding current and the angle of the electrode holder.

Throughout the welding, concentrate on the length of the arc and keep it as short as possible. The length of the arc increases easily as the electrode decreases in size during the welding. The movement may be somewhat difficult to control at first but it is easy to get accustomed,

When the welding electrode runs out, one needs to remove the slag from the previous weld and clean it with a steel brush. Ignite the next electrode slightly ahead of the previous weld and then move the welding electrode back to the previous weld and continue with the welding.

Turn off the welding electrode by moving it slightly back to the completed weld and then lifting the electrode straight away from the work piece.