The arc fuses the material being welded and the welding wire, thus creating the weld. The wire feeder continuously feeds welding wire through the welding gun throughout the welding process. The welding gun also provides shielding gas to the weld.

The MIG and MAG welding methods differ from each other in that MIG (metal inert gas) welding uses an inert shielding gas, which does not participate in the welding process, while MAG (metal active gas) welding employs an active shielding gas that participates in the welding process.

Usually the shielding gas contains active carbon dioxide or oxygen, and therefore MAG welding is by far more common than MIG welding. In fact, the term MIG welding is often accidentally used in connection with MAG welding.

APPLICATIONS

Today, MIG/MAG welding is used nearly everywhere in the welding industry. The largest users are heavy and medium-heavy industry, such as shipbuilding, manufacturers of steel structures, pipelines and pressurised containers, as well as repair and maintenance businesses.

MIG/MAG welding is also commonly used in sheet metal industry, particularly in the car industry, body shops and small industry. Hobbyists and home users also most commonly have a MIG/MAG welding machine.

EQUIPMENT

MIG and MAG welding equipment is typically comprised of a power source, wire feeder, grounding cable, welding gun, optional liquid cooling unit and a shielding gas tank or gas network interface.

The purpose of the wire feeder is to feed the welding wire needed in welding from the spoolcoil to the welding gun.

The wire feeder also allows for starting and stopping the power source and, when using an electronic power source, control the voltage provided by the power source. Therefore the power source and the wire feeder are connected with a control cable. Additionally, the wire feeder controls the flow of the shielding gas. The shielding gas needed in welding is obtained either from a gas tank or from a gas network.

Kemppi-manufactured MIG welding machines are often modular in structure, and the cooling device, power source and wire feeder can be freely selected according to the requirements. The wire feeder can be detached from the power source, thus making it unnecessary to move the entire welding machine from one worksite to another.

The devices may also have a replaceable control panel and separately activated additional features.

The welding gun heats up during welding, and therefore it must be cooled with gas or liquid. In gas-cooled welding guns, the shielding gas running to the gun through the welding cable simultaneously acts as the gun cooler. In liquid-cooled guns, a separate liquid cooling unit is required to recycle the cooling liquid within the welding cable to the gun.

The structure of a MIG/MAG welding machine is restricted by the welding wire coil inside the machine. The coil is often a heavy and space-consuming component. Even so, the most modern MIG/MAG welding machines are stylish, compact machine packages, such as the Kemppi MinarcMig Adaptive 180, which won the Red dot award for industrial design in 2006.

TECHNIQUE

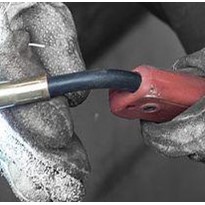

In MIG/MAG welding, the welder’s tool is a welding gun. It is used to introduce the filler material wire, shielding gas and the required welding current to the work piece. The most important issues related to MIG/MAG welding are the welding position, welding gun angle, wire stick out length, welding speed and the shape of the molten weld pool.

The arc is ignited with a trigger in the gun, and the gun is then moved at a steady welding speed along the weld groove. The formation of the molten weld must be observed. The position and distance of the welding gun relative to the work piece must be maintained constant.

It is particularly important that the welder concentrate on managing the molten weld at all times. A moment of wandering thoughts increases the risk of welding errors. In such cases, it is advisable to interrupt the welding for a moment and then resume.