The Customer

Moorebank Aerosol Fillers PTY LTD are a manufacturer of industrial gasses, mostly focussing on contract aerosol filling since they were founded in 1987.

Customer Challenge

Moorebank Aerosols needed an instrument capable of measuring an accurate level of deionised hot water (approx. 75°C). Without this it was required to weigh the materials before batching to insure the most accurate outcome for their product.

Product Solution

After careful reflection, Moorebank Aerosols contacted Innovec Controls interested in the IBL - Batch Controller to aid with their production and safety processes.

Aiding factories around Australia and more, the IBL - Liquid Batch Controller was the best choice for Moorebank Aerosol Fillers challenge and application. The CE approved IBL provided an accurate, easy to use and safe solution for the Moorebank factory and its valued staff.

Results Achieved

The IBL allowed Moorebank Aerosols to safely and conveniently measure liquid materials extremely accurately to 0.001 of a litre. This increased their production process greatly, while also allowing an extra level of safety for the factory staff as they had slightly less handling time of the hazardous materials.

With a newly installed batch controller as of February, Moorebank Aerosol Fillers is now running 3 Innovec IBL instruments, including an explosion proof batcher used with ethanol processes.

IBL - Batch Controller for Liquids

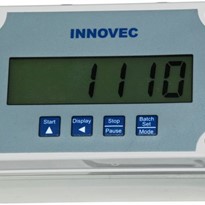

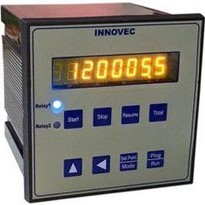

The IBL Batch Controller is an 85 to 265VAC or 12-40VDC powered batch controller for liquids that incorporates a six (6) digit 18mm LCD (liquid crystal) display and integrated back light. The instrument can be configured from the front touch buttons to batch volumes from 0.001 to 999,999 litres and K factors from 999,999 to 0.01 can be utilised. The instrument can batch in up or down mode and provide the excitation power supply for the flow sensor.

Key Features

- Batch in local or remote mode up or down from set point

- Simple touch switch programming with English statement prompts

- Low cost - High performance

- LCD display of 6 characters with 18 mm digit height and white LED backlight

- Low flow alarm with batch cancel

- Programmable end of batch signal with an end of batch pulse of 0.0 to 99.9 seconds

- Background total

- Programmable delay on relay two start and pre-stop

- Batch set from front panel in programme mode or in run

- Pulse output per litre

- Automatic over run compensation in whole litres only

- Dip switch selectable input: turbine, reed switch, open collector, Namur & CMOS logic

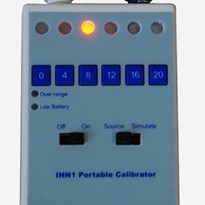

- Sensor supply that can be adjusted from 8 to 20VDC

- Plug in screw terminal electrical connections

- K factor 999,999 to .01 and set point 0.001 to 999,999

- 85 to 265VAC 47-63 Hz supply or factory fitted 12 to 40VDC isolated supply

- Optional clear silicon weatherproof boot to give front panel protection to IP67

-205x205.jpg)