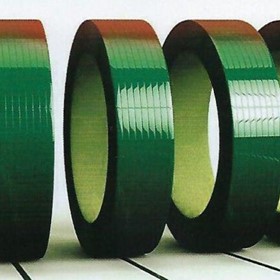

If the volume of goods you are strapping is not high, or if you need to occasionally strap product onto pallets, or to secure and bundle, then light gauge poly strapping is the answer.

If, however, you need to unitise a heavy load, then heavy gauge poly strapping is called for. Heavy-duty poly has taken over from steel strapping in most instances, simply because it caters for a small amount of stretch if the load shifts, whereas steel strap will simply come loose.

Manual strapping requires a Tensioning Tool, a Crimping Tool and Crimps or Seals as they are otherwise known.

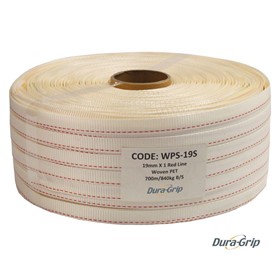

First, select the gauge of poly strap you need to use. This is shown as a load kilogram rating. For heavy loads requiring many constraints, go for the higher load rating.

Your Tensioning and Crimping tools must match the force required to hold and seal the strap.

There is also a choice between manual and powered tensioning tools. Powered Tensioners are usually used with heavy gauge strapping, and are battery operated. It allows the operator to hold and use the tensioner in one hand, after placing the strap end and the strap loop into the tensioner body.

A squeeze of the trigger and the strap tensions then is friction welded at the same time, thereby creating a bonded seal. The loop is cut and the Tensioner removed.

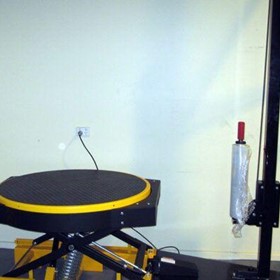

When unitising a load to the pallet, the poly strap end is passed under the pallet using either a flexible rod with a strap clip, or a broom handle, or a specialised piece of equipment that feeds the strap under, up and over to meet the operator, who then simply takes the loop and the end and feeds them into the tensioner. Naturally, this type of equipment is used only when a potential health and safety risk has been identified with strap feeding, or the volume of goods being strapped makes the purchase worthwhile.

-280x280-state_7.jpg)

-280x280-state_7.jpg)

-280x280-state_7.jpg)