Low Co2 emission construction and cladding materials have suddenly become a VERY SERIOUS CONSIDERATION IN CONSTRUCTION, not just in Australia, but around the globe!

NEW HI SPEED PRODUCTION LINES INVESTMENT HAVE SUBSTANTIALLY REDUCED THE COST OF COMPOSITE CLADDING, IN SOME CASES UP TO 50% LESS THAN INSTALLS OF 16MM FYRCHEK AND SIMILAR FIRE RATED PLASTERBOARD

New discriminatory tender price penalties for High Co2 ,low sequestration products in Europe

Some countries like Norway, recently began applying an additional default add on pricing % ,relative to the levels of Co2, turning a low tender price into the highest.

They use an assessment scale of Co2 pollutive values, seriously affecting products like plasterboard which have LITTLE OR NO ( CCS) CARBON CAPTURE SEQUESTRATION VALUE.

These Co2 pollutive assessments may well be expected to be expanded through Australian Federal Govt intervention, if reluctance to change is not observed ,as they move toward the 43% reduction accord

The plasterboard industry in Australia, in manufacturing and distribution is already being affected as public opinion and construction responsibility in terms of Govt 43% emissions reductions, weighs in rapidly on NON Co2 sequestering products.

Products like plasterboard paper lined cladding are beginning to be seen as Pariahs with 95% Co2 pollutive values and the additional destruction of Oxygen generating Co2 absorbing green trees to make ( now not so cheap) paper linings

WHO HAS BEEN USING MgSO4 PRODUCTS IN AUSTRALIA

GOVERNMENT AND PRIVATE CONSTRUCTION

PHOTOS, COURTESY FIRECRUNCH AUSTRALASIA PTY LTD

Worldwide demand for low Co2 construction products

Reduces costs

The huge surge in demand for low Co2 composites and high Carbon sequestration products in cladding and general construction, has over the last 2 years seen substantial new investment into hi speed, computer driven production lines, reducing costs.

These have substantially reduced production costs OF MgSO4 COMPOSITES like Firecrunch and instead of being an expensive green solution, they, as of now in 2023, are similar, and sometimes lower than conventional 13mm and 16mm Fyrchek and similar Fire rated plaster board cladding products in Australia.

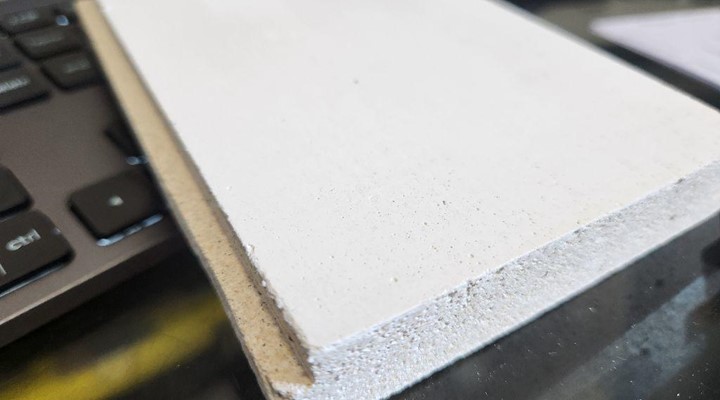

Hi Impact stronger 1.15g/cm3

These very strong hi impact Magnesia (MgSO4) products are up to 8-10 times stronger than plasterboard and enable a single 10mm sheet ( CSIRO) to cover fire for FRL 90/90/90 (90 minutes), otherwise requiring 2 layers of 16mm Fyrchek and similar plaster board

Plus 50% less in install time ,material costs and freight

This halves the material cost ,site handling, installation, freight weight transport cost crane up time and halves the screw fixings materials cost. This all increases a projects ROI

MgSO4 cladding composites have no paper linings

These MgSO4 composites have no paper linings, so are better suited to wet areas and humid climates and in one MULTI-PURPOSE material, covers FIRE, FLOODS ACOUSTICS, TERMITES, BACTERIA, MOULD and heavy IMPACTS, while providing a longer life and low maintenance life with nothing to wash way or rot, with no paper linings

Better for climate planet and humanity

All these extra benefits in one material, while better addressing the lowering of Co2 emissions and having a high Carbon sequester value in retaining carbon emissions (CCS) Carbon Capture Sequestration

( NEW SCIENTIST magazine USA) CCS.

Decreases Tree Destruction

This change will afford gradual reduction in the destruction of millions of Oxygen generating Co2 absorbing green trees to make , (Now not so cheap ) Paper lined plaster board !

No changes for Trades

Set flushed joints same as plasterboard prime and paint

MgSO4 magnesia Oxy-sulphate boards are screw fixed with power tool. They have recessed edgeso on cladding 30mm wide to use regular tapes compounds and provide a top class 4/5 surface finish after priming, under coat, and 2 finish water based paints. Similar or lower m2 material cost half the time and half the material to complete installs in higher fire FRL

Conclusions moving forward

Responsible Architectural and all small and major construction should consider embracing these new greener technologies in pursuit of contributing as much as possible to the reduction in Global warming.

Every step no matter how small is a contributor

Editorial article by Peter Jones /Administration Director

-160x160-state_article-rel-cat.png)