- Magnesium oxide board (MgO) and how it fits into Australian construction.

- NEW multipurpose MgO building products handle fire, floods, impact, termites, mould, bacteria and ALL at a surprisingly low cost.

- New developments with NON Corrosive magnesium sulphate composite mix, changes the way MgO is now fully accepted while specifically excluding corrosive magnesium chloride from the content.

MgO board, as it is commonly called has been around a long time, but not here in Australia where plasterboard linings and cladding have dominated the construction industry for decades and controlled as they still are today, by a few major companies.

Some of these plasterboard companies, have over the decades also been responsible for the irresponsible promotion and sales of dangerous life shortening building products containing asbestos in manufacture, before legislation outlawed its use.

Australian plasterboard building material manufacturers

Currently, still nothing is being changed in an industry that has been crying out for decades for a better cladding solution in terms of the capability of such plaster products, in impact, security, water and flooding, where it absolutely just falls apart and has to be completely replaced. In comparison, MgO sheets will dry out in 48 hours with no physical change in the product and can be resealed and repainted at minimal cost and mess.

Plasterboard also destroys millions of oxygen producing trees each year in the pursuit of millions of kilometres of paper to line this ineffective weak and low strength building product.

Environment benefits extensively with MgO

MgO is a carbonation material (45%) of recycled waste, which is manufactured at kiln temperatures half that of plasterboard, around 650 deg Celsius.

So only 50% of Co2 is produced by MgO.

However the MgO product needs to carbonate (ie. cure, over around 3 weeks at controlled humidity) and in doing so draws back some 90% of the Co2 it produced in manufacturing, making this a low 5% contributor of Co2 and without destruction of millions of oxygen producing trees each year.

So MgO is a “double whammy benefit” to the environment (tree friendly)!!

Corporate and Govt responsibility should lead the way

Large corporations and superannuation funds, commissioning construction or investment and the insurance investment industries, need to address the issues of environmental public concern and environmental responsibility in new construction, and if not, substantial and sometimes irreparable damage is done to such corporate and potentially political reputations.

Extensive consideration to matters like this by Government departments are now turning their own specifications to ensure environment and responsibility, is demonstrated wherever possible.

Whilst MgO Boards may not be the best friend of the plasterboard industry it's certainly in the best interests of the users, buyers and the environment in the immediate and long term.

Health with MgO

Health issues with paper based plasterboard with mould and mildew are legendary and as such invokes the growth of bacteria in and on paper, particularly in wet areas, showers, bathrooms and high humidity parts of Australia. MgO eliminates all forms of mould, mildew and “bacteria” cannot survive on MgO board, so it is ideal for hospitals, medical centres, schools, public buildings and similar high density areas, where health is an issue.

MgO has been cited in periodicals and on web sites dealing with those suffering severe allergies as being totally unaffected as compared with plasterboard and other manufactured products in claddings and linings.

Maintenance of timber homes

For those that live in modern low cost construction brick veneer timber framed homes, termite attacks are inevitable and unseen. There are 4 primary termite species on the east and south coast of Australia that can destroy the average timber lined home in a year.

Plasterboard offers no such protection in this direction at all! In comparison, termites cannot get through MgO boards.

Low lying flood prone areas and bush fires

For those in flood and fire prone areas, much the same applies and exterior type so called water resistant and fire resistant plaster board can require “multiple layers” of 13mm and 16mm plasterboard when needing 1 to 1.5 hours protection. This has become more and more unacceptable, when 1 layer of 10mm MgO board will achieve the same BCA DTS fire tested result up to 1.5 hours so in modern high rise, low rise and fire separation walls MgO can reduce cost of labour and materials by up to 70% and increase ROI in all projects with more tenancy space due to thinner walls, etc.

So it's ideal for use in high rise inter-tenancy walls, low rise, duplexes, townhouses, cluster developments, factories, commercial units, etc. all with common walls.

Light weight building construction

Architects and designers are at the forefront of such changes and with clients who are demanding more, not just in cost considerations, but in long term low maintenance and environmental support issues.

Light weight construction is the new move in economic construction whether it’s free standing homes site built or prefabricated new products like MgO.

MgO with NATA / CSIRO FIRE tested products is 10 times stronger than any plasterboard, Fyrchek etc. It won't degrade in water or flooding and can withstand fire for 1.5 hours and more in meeting BCA Aust standards which otherwise require, multiple layers of fire rated plasterboard. In high rise construction, cost of labour and materials can be cut between 50% and 70% which is extensive in major high rise construction projects.

The thinner, stronger 10mm MgO board replaces 2 x 16mm Fyrechek or similar fire rated plasterboard and increases rental lease space with use of thinner 10mm walls sections. The ROI and the development get a double hit in saving. Plus add transport (weight) halved, site handling is halved and crane up time is halved, plus the likely higher returns due to larger lease, rent or buy floor areas.

Acoustics are maintained at Rw 62 plus ctr net 52 and above BCA requirements (Rw50) on a double stud discontinuous frame.

FCA MgO easily contains bush fires to max BAL (FZ) Flame zone which is only FRL 30/30/30.

Other uses for MgO

The product is made with thicknesses from 3mm to 25mm.

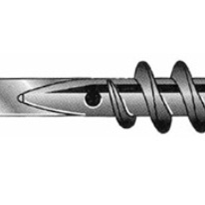

- Various edges in SQ recessed for plaster set joints SE and TE..V Groove board 12mm TS12 .

- Tongue and Groove TG board for floors and decks in 16mm and 19mm.

- “Timber look-a-like” weatherboard panels, totally non combustible for bush fire areas

- Used for construction, doors, hatches, kitchen and bathroom furniture and can be surface and edge laminated

- Decorative surface for facades or internal decoration finishes in timber, decorative designs and colours at much lower costs and lighter than heavy pollutive CFC

Changes in MgO products

Most MgO products out of China, where all Mgo board almost without exception is manufactured, have a mix of Magnesium Oxide and (MgO) and Magnesium Chloride (MgChl2).

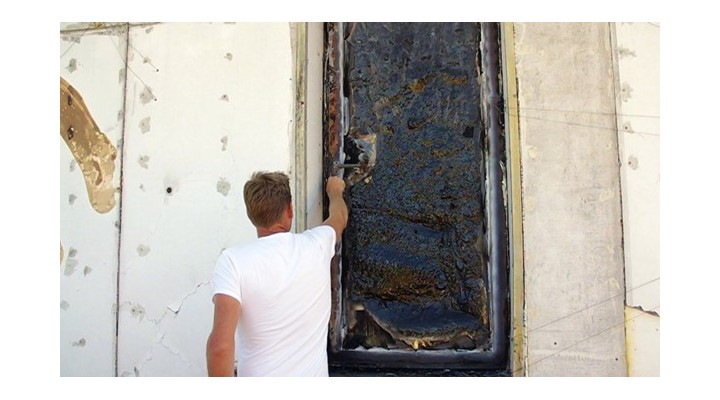

Whilst the board in this form is still excellent for fire, flooding, termites, etc, it can suffer quite badly in terms of wet areas and humidity when in contact with metal surfaces even (20 Ga) Galvanised steel due to the chloride content.

Users should be careful in selecting an MgO board product which contains chloride as it is not just the steel framing but the steel fixings can be corroded as well with chloride IONS reactions.

The products to look for are (MgSO4) using a magnesium sulphate bonder not chloride

Use of any of these products in Australia requires the user to ensure that the product has also been tested to Australian standards under the BCA DTS (deemed to satisfy) provision by fire accredited testing authorities like NATA accredited CSIRO or Exova Warrington. This also need a Non Asbestos NATA accredited lab test under AS 4964.

Such compliance certificates must be obtained from every MgO supplier before use or final certification will be refused.

Sourcing MgO products in Australia

MgO is not an off the shelf item in Australia with only a few companies importing the product often for a self purpose use and virtually none carry on call stock, or even have the required range of ABCB /NCC certifications.

---------------------------------------------------------------------------------------------------------------

Availability in Australia

Firecrunch Australasia PL is a compnay that does have the non chloride product Magnesium sulphate (MgSO4) known as Firecrunch FCA.

FCA carries warehoused stocks in the three eastern State capitals in QLD, NSW, VIC and ACT and has been Fire Tested by NATA accredited testing authority, CSIRO Infrastructure Technologies North Ryde Sydney under ISO/IEC 17025 AS/1530.4-2005/16 and valid until 2025 .

Certificates of Australian Fire testing in BCA compliance can be seen on the web site at www.firecrunch.com.au/certification with an extensive range of support, technical and installation manuals and other information.

For more information on the MgSO4 board, please contact us via the IndustrySearch enquiry form.