The Epson SurePress™ range represents a breakthrough in label production. It has never been easier to go digital and you can do it with machines that are compact, offer wide media compatibility and high production flexibility. Equipment is easy to install, easy to maintain, and cost effective to run. Jobs can be set-up and completed quickly with low wastage and minimum labour. They produce output with outstanding print quality that is suitable for a wide range of consumer and industrial applications.

The SurePress L-6034VW digital label press features Epson’s latest heat-free PrecisionCore® line ink-jet printhead technology and industrial grade Epson UV ink. It is designed for converters who wish to produce quality labels with a durable finish in short to medium print runs. The press is compatible with a wide range of paper and film stocks, producing high resolution output with outstanding scratch and weather resistance. Jobs are quick to set up and fast to complete with minimum effort and wastage. Machines are compact, cost effective to run, and can be managed by a single operator. Output is compatible with a wide range of industry standard finishing equipment to enable a low set-up cost with maximum production flexibility. The press is packaged with ESKO RIP software and can be ordered with an optional X-Rite spectrophotometer for work with custom media.

Features at a glance

- Superior Print Quality – Epson heat-free PrecisionCore line heads with 600 x 600dpi max resolution, VSDT, and in-line pinning.

- Superior Colour with an Outstanding Finish & Print Durability – 5 colour UV ink set with an enhanced gamut + White, selectable Digital Multi-Varnish, optional integrated colour management.

- Fast Job Turnaround – Fast media loading, rapid configuration, digital image processing, supports production speeds up to 15m/ minute1.

- High Production Flexibility – Variable frame lengths, variable print lengths, fully adjustable label sizing, compatible with a industry standard substrates from 80-340mm wide, integrated re-winder; optional in-line curing, in-line corona treatment, X-Rite spectrophotometer and variable label content support.

- Easy Operation – Touch-screen display with simple menu structure and user-adjustable pre-sets, supplied with a choice of RIP software.

- Reduced Running Costs – Cost-effective bulk ink system, achieves print speed rapidly for reduced substrate wastage, single operator management with minimum job oversight, automated nozzle status checking and head cleaning, reduced cleaning/ mechanical maintenance and system downtime .

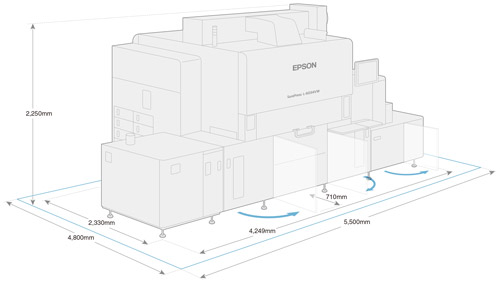

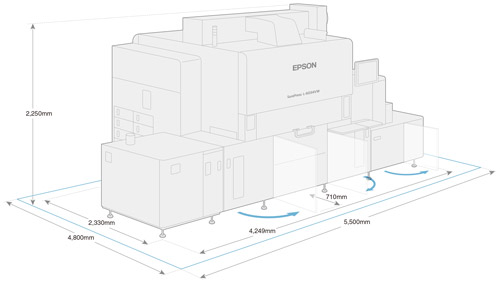

- Simplified Installation – compact & space saving design, requires a basic ozone extraction system, supplied and installed by Epson in conjunction with authorised dealer/integrators2.

- Simplified Handling with Reduced Environmental Impact – no film or plates, ink shipped in crushable bags & loaded via re-usable vacuum cartridges.

The L-6034VW digital label press features advanced Epson heat-free PrecisionCore® line inkjet print-head technology with multiple heads positioned around a rotating drum with LED partial curing (pinning) lights. The large drum and cool LEDs ensure consistent and predictable imaging with minimal media expansion/ shrinkage while an advanced web transport system with direct steering ensures precise tracking. Each head incorporates hundreds of micro-fine nozzles that are precision engineered with an electro-mechanical operation for ultra-precise drop formation and placement. The heads enable superior and consistent print with remarkably sharp detail. Labels can be produced with crisp small type, fine line art, and extremely accurate bar codes. Integrated Epson Variable-Sized Droplet Technology (VSDT) enables different sized droplets to be produced for smooth gradations, optimum ink application and minimum consumption.

UV ink3 provides excellent weather, scratch, chemical, and water resistance. The Epson formulation features an advanced construction that provides an enhanced gamut with brighter colour. It was developed specifically for industrial label production and is manufactured to extremely high precision under an ultra-clean environment for consistent and predictable performance. It adheres directly to a wide range of substrates including paper, clear and metalized films, without the need for surface treatments or coatings. It ships in large and cost-effective bags that are not only efficient to transport and store, but are also crushable for easy disposal. The colour set incorporates a high-opacity White ink that can be applied in-line as a surface colour or as a separate layer in a multi-pass print run. It also includes a Digital Multi-Varnish that can be applied with a selectable matte or gloss finish, on a spot basis or as a wash, for additional durability and presentation value. An optional in-line corona treater is available while the integrated in-line pinning system ensures dot shape and positioning is maintained for superior imaging with precise edge definition, even tonal gradations, and low graininess. The in-line pinning system ensures accurate dot shape and positioning for superior imaging with precise edge definition, even tonal gradations, and low graininess. With SurePress you can produce premium quality output that is predictable and consistent with a finish that is durable, bright and packed with punch.

Epson's SurePress™ digital label press provides an innovative solution for short to medium run print jobs. The digital process ensures make-ready time is dramatically reduced while substrate changeover is quick and easy. An integrated take-up and optional in-line UV curing unit enable roll to roll production with no requirement for colour adjustment or drifts in the registration mark, from the first frame to the last. The press requires minimum oversight and can be managed by a single operator via a simple menu driven touch-screen panel with user-configurable pre-sets. There is none of the plate or film waste involved with traditional print processes and the press achieves print speeds quickly for minimum media wastage. Short-run jobs that were traditionally difficult, time consuming and costly, can be produced quickly, efficiently and profitably. Ink bags are loaded via clean and convenient reusable cartridges. They are inserted in pairs for maximum capacity and can be replaced while printing continues. The UV pinning system features long-life LEDs while the print-heads incorporate an advanced nozzle status analysis and error detection system that requires no ink ejection and operates continuously, engaging a cleaning wiper automatically as and when required.

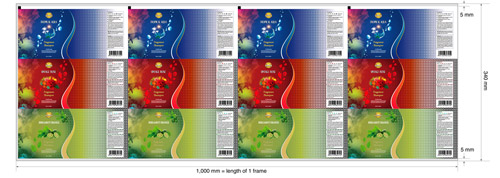

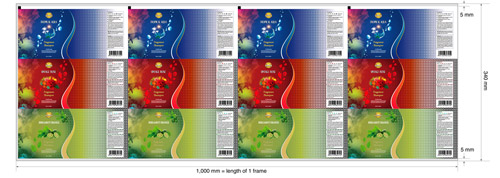

The L-6034VW not only delivers on print quality and operational ease, but also output versatility. It prints in adjustable frames up to 1000mm in length on a huge variety of off-the-shelf substrates up to 320 micron thick and 340mm wide. An optional in-line corona treater provides enhanced media support while the LED pinning system enables operation with heat-sensitive substrates such as PE. An optional in-line curing system works with the integrated re-winder to enable rapid roll-to-roll production with adjustable tension control to suit wide range of industry standard finishing equipment. The LED pinning system provides support for heat-sensitive substrates such as PE while the integrated re-winder and optional in-line curing system enable rapid roll to roll production. Precision alignment and adjustable tension control on the re-winder ensure output rolls are suitable for a wide range of industry standard finishing equipment. Installing an Epson SurePress will not only boost your marketability but leave you amazed at how flexible and cost effective your operation can become.

Driving our best-in-class digital label press is achieved through the use of RIP package from ESKO. The ESKO RIP software has been designed to enable simple, flexible, and intuitive production. Options are available to support workflow control, colour management and advanced functionality. An optional i1Pro X-Rite spectrophotometer with appropriate software gives you the ability to create ICC profiles for custom media substrates with colour-accurate results that can be repeated job after job. With optional variable data support you can even output super-premium jobs with serialised, application and customer specific content. By listening to customers and working with industry-leading manufacturers on every aspect of production, Epson has been able to offer a new open approach that makes adoption of digital label production an easy and cost-effective choice.

Specifications

| SIZE |

| Max Media Width |

13.4 inches |

| PRINT TECHNOLOGY |

| Print Mechanism |

6 x PrecisionCore™ linehead with Nozzle State Analysis & auto wiper |

| Head Configuration |

11 x inkjet print chips x 800 nozzles |

| Resolution |

600 x 600 dpi max |

| Minimum Drop Size |

3.2 picolitres |

| INK SYSTEM |

| Family |

Epson UV |

| Type |

LED UV Curable |

| Colour Set & Loading |

2 x (blacK, Cyan, Magenta, Yellow, White)

|

| 2 x Digital multi-Varnish |

| Pack Size |

3L (2.6L White) |

| PRINT PERFORMANCE |

| Print Speed |

Up to 15m/min Normal Mode

Up to 7.5m/min in Reverse White or with Variable Data |

| Note: Print speeds are provided for comparison purposes only. They do not include image processing/ transfer times, are RIP dependant and not all print modes are compatible / recommended for all media types. |

| SUBSTRATE SUPPORT |

| Formats |

3" core roll based

80-340mm wide

100kg max weight

600mm max diameter (including 3" core) |

| Thickness |

3.14 – 12.60 mils / 80 - 320 microns |

| Media Types |

Self-adhesive label stock, PP, PE and PET

Uncoated, coated and cast coated papers |

| Max Frame Size |

1000 x 330mm

|

| Output |

Integrated Re-winder |

| OPERATION |

| Control Panel |

Touchscreen LCD |

| Networking |

Ethernet 1000 Base-T |

| Dimensions (WxHxD) |

4250 x 2485 x 2285mm (complete with Corona Treater & UV Curing Unit) |

| Weight |

Printer 2,710kg

Corona Treater 170kg

UV Curing Unit 190kg |

| ENVIRONMENT |

| Operating Temperature |

20° to 28°C |

| Operating Humidity |

35 to 55% (no condensation) |

| Power Supply |

Printer: 200V AC (Three phase), 50-60Hz, 30A

Corona Treater: 200-240V AC (Single phase), 15A

UV Curing Unit: 200-240V AC (Single phase) 40A |

| Power Consumption |

Printer: 10kVA

Corona Treater: 3kVA

UV Curing Unit: 8kVA |

| Max Operating Noise |

80dB (excluding the alarm sound) |

| External Dimensions (WxHxD) |

5.5 x 2.6 x 4.8m

|

| Minimum Floor Stiffness |

520kg/m2 |

Usage Conditions

Epson products are designed and made to give highly reliable use and long life when used according to its specifications. With any system, product or device used in situations where human life may be involved or at risk, Epson advises that you should take all necessary steps to ensure the suitability of your Epson product for inclusion in your system, and recommends that you include fail-safe procedures and redundancy support or backup equipment in your system, to maintain the maximum safety margin and optimum system reliability. Examples include but are not limited to – do not interfere with any electrical components within the device, do not use items supplied with the product for purposes other than as intended by Epson (ie mains cords, inks, CDs, plastic wrapping) and do not make modifications to the product.

This printer is designed to function only with genuine Epson ink cartridges and not with third party ink cartridges. The printer may not function properly or at all if you use third party ink cartridges.

-280x280-state_7.jpg)