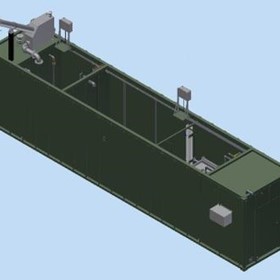

Various designs and configurations enable efficient and economical treatment of most industrial wastewater applications:

- Small “Busta” units are for treating 300 – 500 litres per day. They are manual and economic

- Semi-Automatic units require minimal operator time and are available in stainless steel construction and ideal for treating 750 -1000 litres per hour

- Fully automatic units are PLC controlled and of stainless steel construction

- Treatment rates range from 1000 litres per hour up to 10,000 litres per hour and can continually treat without operator attention 24 hours a day

Equipment and options available with a Baldwin RM-10 treatment system can include:

- Skid mounted oil skimmers, decanters with integrated 5,000 litre waste oil tank

- Coalescing plate separators

- Dirty water collection tanks

- Collection tank agitators / mixers

- Mixer stands

- Pre-treatment pH adjustment systems

- Feed and filtrate pumps

- Post-treatment pH monitoring and adjustment

- Filtration skids

- Conductivity monitoring

- Control panel options

- Skid mounting

- Paint manufacturing – wash water

- Corrugators – ink and glue water

- Vibratory de-burring

- Diecasting

- Metal working coolants

- Plating

- Equipment washdown

- Parts washing

- Phosphate removal

RM10 bag : 5kg

RM10 pallet : 64 x 15kg

-280x280-state_7.jpg)