Whether you’re in the automotive, METS, or engine reconditioning industries, Apollo Engineering’s automated parts washers deliver significant improvements in productivity, cost savings, and environmental impact.

In addition to these industry-leading solutions, Apollo Engineering offers complementary products like EziVac and the EziChem series, designed to enhance the efficiency of your cleaning systems.

Automated Parts Washers: Save Time and Cut Costs

Hand-cleaning parts is not only labor-intensive but also costly. Why pay your staff to spend hours scrubbing parts when an automatic parts washer can complete the job in minutes? Apollo Engineering’s range of parts washers reduces manual labor, freeing up your staff for more critical tasks.

Take our Super Wash SW1400 as an example. Designed for heavy-duty applications, its gear-driven turntable delivers 60% better cleaning efficiency than traditional water-driven models. Programmable timers allow you to schedule cleaning during off-peak electricity hours, reducing operational costs further.

Advanced filtration systems remove particles and contaminants, extending the lifespan of cleaning solutions. Optional rinse and divert machine functions streamline the cleaning process, handling both washing and rinsing in a single operation.

Save Chemicals and Energy with Apollo’s Hot Tanks

Apollo’s Hot Tanks are more than just cleaning solutions—they’re cost-saving powerhouses. These tanks save up to 75% on chemical costs and 25% on electricity, making them an ideal choice for businesses seeking sustainable and cost-efficient solutions.

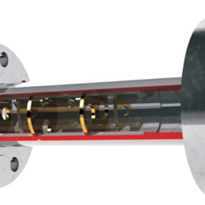

Featuring advanced centrifugal filtration, our Hot Tanks extend chemical life and minimize maintenance downtime. Easy-to-clean centrifuges and durable chemical solutions ensure maximum uptime.

Apollo Engineering offers a variety of tank sizes to suit workshops of all scales. From small engine components to large mining equipment, our Hot Tanks handle the load effortlessly.

Complementary Products: EziVac and EziChem Range

Apollo Engineering’s complementary products enhance the performance and efficiency of your cleaning operations.

EziVac

The EziVac is a high-performance wet and dry industrial vacuum cleaner, built for demanding environments. Manufactured in Australia, it complements our automated parts cleaners and Hot Tanks by keeping workshops clean and debris-free. With its powerful suction and user-friendly design, EziVac ensures enhanced productivity and safety.

EziChem Range

The EziChem range offers specialised chemicals locally manufactured to deliver optimal cleaning performance while minimizing environmental impact.

- EziWash: Formulated to be aluminium safe for spray washers and automated parts cleaners, this solution removes even the toughest grime.

- EziClean: A versatile multi-purpose casustic cleaner for various mild steel paint/carbon and scale removal.

- EziBoost: An additive that boosts the cleaning power of EziClean, ideal for stubborn contaminants.

By integrating EziVac and EziChem with your cleaning processes, you achieve superior results while reducing costs and environmental impact.

How Apollo Engineering Stands Out

Apollo Engineering is committed to Australian-made equipment and superior customer service sets us apart. Our machines are compliant with Australian standards (AS4024, AS1554, AS3000), ensuring they are built to last and meet rigorous safety requirements.

Key features that make our products stand out include:

- Advanced filtration systems that reduce consumable costs and extend the lifespan of cleaning solutions.

- Oil skimmers for ensuring a spotless finish after each cleaning cycle.

- Rinse and divert machines options, enhancing operational efficiency by automating both wash and rinse processes.

- Gear-driven turntables for better cleaning efficiency and safety.

- Programmable 7-day timers for optimised energy use.

- Auto water level tops for easier operation.

- Centrifugal filtration for longer chemical life and reduced maintenance.

- Variety in sizes to handle very large parts, making it ideal for industries like mining and heavy vehicle maintenance.

- Complementary products like EziVac and the EziChem range to enhance overall cleaning and maintenance efficiency.

The Apollo Hot Tank Filtration, featuring a centrifuge and oil skimmer, extends chemical solution life up to 9 years in heavy operations, saving over 75% on chemicals. It also eliminates downtime from tank de-sludging and the need for staff to pump chemicals.

Ready to Boost Your Workshop Efficiency?

Say goodbye to high labor costs, energy waste, and inefficient cleaning processes. With Apollo Engineering’s Spray Washers, Hot Tanks, and complementary products like EziVac and EziChem, you’ll find the perfect solution for your needs.

Don’t settle for less—choose Apollo Engineering, where efficiency meets cost savings.