Explore our mini excavator buying guide for contractors and equipment procurement experts. Learn about costs, financing, and ownership for urban and landscaping jobs.

Key Takeaways

- Weight: Mini excavators in Australia typically weigh between 1.7–5.5 tonnes, ideal for residential or urban jobs with tight access.

- Price: New mini excavators cost $30,000–$85,000+, while used models range from $15,000–$60,000 depending on hours, brand, and condition.

- Usage: Best for trenching, post holes, tight-access demolition, site prep, and plumbing—especially on small or medium sites.

- Transport: Machines under 3.5T are towable by ute and trailer, making them versatile for tradies or rental operators.

- Efficiency: Fuel use ranges from 3–6 litres/hour. Operating costs are low compared to larger excavators.

- Compliance: No licence needed for private use. A RIIMPO320F ticket is typically required on commercial job sites.

- Buyers: Ideal for landscapers, builders, local councils, plumbers, and hire companies seeking high ROI, compact power, and flexibility.

What Is a Mini Excavator?

A mini excavator, sometimes called a compact excavator, is a lightweight digging machine designed for small to medium excavation tasks. Typically weighing under 6 tonnes, these machines can navigate tight access spaces, making them a go-to solution for residential, urban, and light commercial work.

They're often used where a standard excavator is too large or heavy for the site. From backyard pool digs to kerb and channel work for councils, mini excavators fill the gap between manual labour and full-sized machines. In procurement contexts, mini excavators often serve as high-utilisation assets in hire fleets, municipal public works departments, and subcontractor fleets.

Size and Weight Classes

Mini excavators are generally split into three size categories:

- Micro excavators (under 1 tonne): Ideal for ultra-narrow access and indoor jobs

- Compact models (1 to 2.5 tonnes): Great for landscaping, fencing, and plumbing

- Mini class (2.5 to 6 tonnes): Suitable for more demanding excavation tasks with better reach and lifting capacity

The higher end of the mini range — such as 5.5 tonne machines — offers more power and stability without losing the key benefit of compact access.

Key Features to Look For

When comparing models, focus on these features to ensure performance, operator comfort, and suitability for your job types:

- Zero-tail swing: Prevents the rear of the excavator from extending beyond the track width during rotation, ideal for working next to buildings, fences or walls.

- Retractable undercarriage: Allows the width of the tracks to contract for entry through narrow gates or laneways, then expand for stability once on site.

- Rubber tracks: Reduce surface damage, especially important for driveways, turf, and pavement work.

- Quick-hitch systems: Let you change attachments rapidly, keeping downtime to a minimum on-site.

Attachments and Versatility

Mini excavators are valued for their ability to handle multiple jobs thanks to a wide variety of compatible attachments. Popular options include:

- Standard digging and trenching buckets

- Tilt buckets for shaping and finishing

- Augers for post-hole or pier drilling

- Rock breakers and hydraulic hammers

- Grabs, thumbs, and rippers for material handling or demolition

This makes a mini excavator a multi-functional asset on any site, especially when paired with a quick-hitch system.

Pricing in Australia: New vs Used

Mini excavator prices in Australia depend heavily on brand, machine weight, attachments included, and condition. Typical costs include:

- New machines: $30,000 to $85,000 or more, depending on features and brand (e.g., Kubota, Takeuchi, Yanmar, Hitachi, Caterpillar, Kobelco)

- Used machines: $15,000 to $60,000, depending on hours and maintenance history

- Off-brand or imported models: Can be cheaper, but buyers should consider local parts support and resale value

Financing options are widely available from dealers and lenders, especially for sole traders and ABN holders.

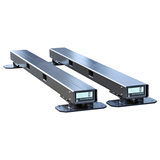

Transportation and Site Access

One of the standout advantages of a mini excavator is how easy it is to move from site to site.

- Models under 3.5 tonnes can often be towed using a dual-axle trailer and a suitable ute or light truck, reducing transport costs

- No tilt tray or heavy-duty float is needed for most models in the 1.7 to 3.5 tonne range

- Narrow models and those with retractable undercarriages can pass through gates, laneways, and tight driveways

Always check local towing regulations to ensure your tow vehicle and trailer meet legal weight limits.

Operating Cost and Fuel Efficiency

Mini excavators are among the most fuel-efficient machines in the field.

- Fuel usage typically falls between 3 to 6 litres per hour

- Smaller engines and lightweight designs mean lower servicing and maintenance costs

- Downtime is reduced with routine care, especially when using quality filters, fluids, and regular grease intervals

Hydraulic systems are a key maintenance focus — clean oil and hoses free from contamination will extend machine life significantly.

Licensing and Training Requirements

Most states and territories in Australia do not require a formal licence to operate a mini excavator under 2 tonnes on private property. However, when working on construction sites or commercial jobs, you may need:

- RIIMPO320F: Conduct Civil Construction Excavator Operations — a nationally recognised unit of competency

- Verification of Competency (VOC): Especially required on major civil or government-funded works

- Always follow Safe Work Australia and state-specific guidelines (e.g., WorkSafe VIC, SafeWork NSW)

Insurance providers may also require operators to demonstrate competency.

Warranty and Servicing Considerations

Protect your investment by reviewing warranty and support terms before purchase.

- Most new machines come with a 1–2 year standard warranty, with some offering extended plans

- Choose suppliers or dealers with strong after-sales support and access to mobile service units

- Availability of spare parts should be a key consideration — well-known brands generally offer quicker parts turnaround

- Second-hand machines should be inspected for service history, wear on pins and bushings, and overall hours

A strong service plan can extend machine life and support resale value.

Who Should Buy a Mini Excavator?

Mini excavators are a strategic fleet asset for:

- Local councils: For public works, parks, and facility maintenance

- Hire companies: As high-demand, versatile units with low TCO

- Trade contractors: Especially plumbers, landscapers, and fencing crews looking to reduce external hire costs

- Civil contractors: Needing urban-friendly machinery for utility and subdivision work

They offer a low barrier to entry, strong ROI, and rapid deployment potential — making them a cornerstone machine in any compact machinery strategy.

Final Thoughts

Mini excavators offer a powerful combination of flexibility, affordability, and practicality. Whether you're breaking ground on a backyard project or managing multiple small contracts, these machines deliver serious value in a compact package.

Choosing the right mini excavator depends on your job type, transport setup, and budget. Be sure to prioritise dealer support, attachments, and long-term operating costs — and you’ll end up with a machine that works as hard as you do.