At the forefront of this evolution is AGEN Robotic Structural Steel Assembly (RSSA)—an innovator enabling traditional workshops to transform into fully automated, intelligent factories.

Emerging Trends in Robotic Fitting and Welding

The structural steel and heavy fabrication industries are embracing these breakthrough automation trends:

- Full Automation of Steel Assembly. Robotic systems now handle complex welding and fitting tasks with minimal human input, reducing labour dependency, eliminating inconsistencies, and improving throughput.

- Advanced Sensing and Adaptive Control. Robots equipped with real-time sensors and adaptive control systems dynamically adjust to variations in parts, joint gaps, and material conditions—delivering consistent weld quality regardless of part complexity.

- Rise of Collaborative Robots (Cobots). Cobots work safely alongside humans, blending robotic precision with human intuition. This hybrid approach boosts workshop agility and accelerates automation adoption.

- IoT Integration and Predictive Analytics. IoT-enabled robotic systems collect operational data, offering insights to optimise workflows, schedule maintenance, and reduce unplanned downtime.

- Artificial Intelligence and Machine Learning. AI-powered robots now learn from historical data and improve with each task. These intelligent systems support autonomous decision-making and reduce manual supervision.

How AGEN RSSA Leads the Robotic Manufacturing Revolution

AGEN RSSA is setting a new benchmark in robotic steel assembly through innovation, integration, and performance. Here’s what sets them apart:

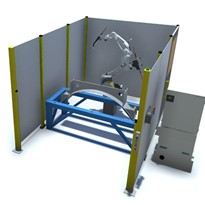

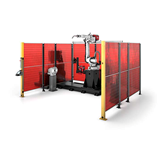

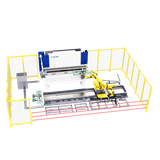

- Turnkey Automation for Structural Steel. AGEN delivers full-system automation for beam fitting, welding, and layout marking. These robotic platforms streamline entire workflows, ensuring faster project delivery and precision at scale.

- Next-Gen Robotic Platforms. Designed for complexity and built for performance, AGEN’s robots handle non-standard beam geometries, thick plate welds, and high-mix production environments with ease—reducing reliance on manual processes.

- Human-Robot Collaboration with Cobots. AGEN’s cobot systems enhance operational safety and flexibility. Easy to deploy and reprogram, they allow small-to-mid-size workshops to integrate robotics without overhauling existing layouts.

- Real-Time Data and IoT Monitoring. Through seamless IoT integration, AGEN’s robotic lines capture critical operational data—empowering fabricators to make data-driven decisions and unlock predictive maintenance benefits.

- AI-Driven Continuous Improvement. With embedded AI and machine learning capabilities, AGEN’s robots adapt over time, improving weld accuracy, cycle times, and part recognition—delivering true intelligent automation.

The Future of Fabrication is Robotic—and AGEN is Leading the Way

The future of robotic welding and steel assembly is not just promising—it’s already here. AGEN RSSA is enabling steel fabricators to reduce labour costs, improve output quality, and remain competitive in a rapidly changing market. Their advanced robotic technologies are redefining what’s possible in structural steel manufacturing. Transform your workshop into a smart factory. Partner with AGEN RSSA—where automation meets precision.

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)