Research shows that if part reliability drops below 80%, performance gets worse. If reliability falls under 20%, the system might work better than at mid-levels but still isn't safe. Good-quality parts also reduce breakdowns, saving money on fixes and lost work time. To get these benefits, buy parts from reliable sellers to ensure they are strong and fit properly.

Key Takeaways

-

Good excavator parts keep work smooth and safe. Buy from trusted sellers to prevent accidents and fewer breakdowns.

-

Learn about important parts like hydraulics, undercarriages, and engines. Knowing their jobs helps keep your machine working well.

-

Pick strong materials like Hardox steel for long-lasting parts. Tough parts work better and save money on fixing things.

-

Use OEM parts for safety and trust. They fit right and follow strict rules, making them great for big tasks.

-

Read reviews and ask experts before buying parts. Real stories help you choose wisely and avoid wasting money.

Key Excavator Parts and Their Roles

Excavators need important parts to work well. Knowing these parts helps you keep your machine in good shape. Below are three main types of excavator parts.

Hydraulic System Components

Hydraulic systems make excavators dig, lift, and turn. They include pumps, hoses, cylinders, and valves. These parts work together for smooth and strong movements. Good hydraulic parts make machines more reliable and efficient.

New hydraulic technology can save fuel and speed up work. The table below shows how hydraulic systems improve performance:

|

Metric |

Description |

|---|---|

|

Increased Productivity |

New technology must prove it improves work output. |

|

Reduced Fuel Consumption |

Using less fuel is a big reason for new systems. |

|

Improved Cycle Times |

Faster cycles mean better efficiency and reliability. |

|

Enhanced Control Systems |

Better controls improve how well excavators perform. |

|

Increased Horsepower |

The CASE CX800B excavator has 17% more power, boosting work. |

|

Increased Digging Force |

Auto Power Boost adds 10% more digging strength, improving reliability. |

|

Energy Saving Features |

Smart systems lower costs and make machines more reliable. |

|

Condition Monitoring |

Checking parts helps keep systems working well. |

Strong hydraulic parts reduce breakdowns and help you get more done.

Undercarriage Parts

The undercarriage supports the excavator and helps it move. Tracks, rollers, and idlers are key parts. These parts wear out quickly, especially on rough ground. Good care and strong materials make them last longer.

Undercarriage parts usually last 2,000 to 7,000 hours. Problems like misaligned tracks or rust can shorten their life. New designs, like stronger rubber tracks and sealed rollers, last longer and need less care.

Self-cleaning tracks and tough rollers keep the machine steady and moving. Choosing good undercarriage parts helps your excavator work well in tough places.

Engine and Powertrain

The engine and powertrain give the excavator its power. New engines with turbocharging and electronic fuel injection use less fuel and work harder. These features also make engines last longer and stay reliable.

The table below shows how engine quality affects fuel use and performance:

|

Evidence Description |

Impact on Fuel Efficiency and Operational Performance |

|---|---|

|

Advanced engine technologies (turbocharging, electronic fuel injection, hybrid powertrains) |

Use less fuel, give more power, and last longer. |

|

Development of fuel-agnostic engines |

Work with different fuels, save fuel, and cut emissions. |

|

John Deere’s 85 P-Tier excavators |

Have 18% more power, saving fuel and boosting work. |

Good engines lower fuel costs and improve how well your excavator works. Reliable engines handle heavy jobs without problems.

Attachments and Tools

Attachments and tools make excavators more useful for many jobs. These parts let you adjust your machine for different tasks, improving work speed and output.

Buckets, grapples, and hydraulic breakers are key for digging and breaking. Quick couplers help you switch tools fast, saving time on site. For instance, the Genesis XLP tool allows quick jaw changes, so you can do more jobs without delays.

Attachments give contractors great benefits. Small excavators with changeable tools can handle many tasks daily. This reduces the need for extra machines, cutting costs and making work easier. Cheaper linkage tools are helpful for road and bridge jobs where budgets are tight.

Special tools also help in specific industries. Tiannuo grab arms work well in railway building, recycling, and ports. A railway project saw a 37% rise in material handling speed. A recycling plant processed materials faster and sorted them better. Ports handled 28% more daily loads using these grab arms.

|

Evidence Type |

Description |

|---|---|

|

Versatility of Attachments |

Contractors can switch attachments throughout the day, enabling diverse tasks. |

|

Cost Savings |

Lower-cost linkage tools save money for road and bridge projects. |

|

Flexibility |

Genesis XLP allows quick changes between jaw sets, enhancing efficiency. |

|

Quick Couplers |

Faster attachment changes reduce downtime on job sites. |

|

Application |

Improvement |

|---|---|

|

Railway Construction |

37% improvement in material handling efficiency with Tiannuo grab arms. |

|

Recycling Facility |

Reduced processing cycle times and better separation of recyclable materials. |

|

Port Facilities |

28% increase in daily tonnage processing using specialised grab arms. |

Picking the right tools and attachments helps your excavator do more jobs and get better results in different areas.

Features of High-Quality Excavator Parts

Durability and Material Standards

Durability is very important for excavator parts. Strong materials help parts handle heavy loads and tough conditions. Hardox 400 steel lasts up to 24 months because it is stronger and harder. Regular steel lasts only 12 months due to lower strength. Hardox steel also boosts load capacity by 20%, making it great for hard jobs.

Hardness affects how well parts perform. Harder materials carry heavy loads without bending, improving efficiency. For example, strong buckets are better for tough digging tasks. They dig faster, need fewer repairs, and increase work output.

|

Steel Type |

Tensile Strength (MPa) |

Hardness (HB) |

Lifespan (Months) |

|---|---|---|---|

|

Hardox 400 |

1100 |

400 |

24 |

|

Conventional |

800 |

250 |

12 |

Compatibility with Excavator Models

Parts must match your excavator model to work properly. Using the wrong parts can harm performance or damage the machine. Incorrect parts may cause safety problems or make the equipment less reliable.

To avoid issues, learn what your excavator needs. Manuals or expert advice can help you pick the right parts. This ensures your machine works safely and efficiently.

-

Wrong parts can harm performance and damage equipment.

-

Safety problems may happen if parts don’t fit correctly.

-

Manuals or experts help you choose compatible parts.

Manufacturer Reputation and Certifications

A good manufacturer shows their parts are high-quality. Reliable brands follow strict checks to make sure parts work well. Certifications like ISO 9001 prove the parts meet global standards.

Testing agencies like TÜV Rheinland and SGS check parts for strength and reliability. These tests give you confidence that the parts will last and work properly.

|

Criteria/Tests |

Description |

|---|---|

|

Quality Management System |

ISO 9001 ensures strict checks on materials, processes, and finished products. |

|

Joint Testing and Certification |

Agencies like TÜV Rheinland and SGS confirm product strength and reliability. |

Choosing parts from trusted brands ensures they last longer and work better.

Warranty and Customer Support

When buying excavator parts, think about the warranty and support. A good warranty shows the maker trusts their product. It also reassures you that problems will be fixed quickly.

Trusted sellers, like YNF Machinery, know warranties matter. They cover defects and promise high-quality parts. This lowers the chance of surprise costs or delays.

Customer support is just as important. If issues arise, helpful support can solve them fast. Whether you need advice on parts or fixing problems, a skilled team keeps your work running smoothly.

Tip: Check warranty details and support options before buying. These can save you money and time later.

Manufacturers watch warranty claims to check product quality. Many claims may mean reliability problems, raising repair costs and lowering satisfaction. Spending on quality control reduces claims, improves reliability, and builds trust.

-

Big equipment makers track warranty claims to check quality.

-

More claims mean higher repair costs and less happy customers.

-

Quality checks cut claims and make products more reliable.

Picking a seller with strong warranties and great support gives you dependable parts and a smooth experience. This protects your money and keeps your excavator working well.

How to Choose Reliable Excavator Parts

Evaluating Equipment Requirements

Picking the right excavator parts starts with knowing your machine's needs. Each excavator has different requirements based on size, model, and job type. Understanding these factors helps your machine work better.

Think about the tasks your excavator does. For tough jobs like mining, choose parts that handle heavy stress. For lighter work like landscaping, pick parts that improve accuracy and efficiency. Matching the machine size to the job is also important. Small machines may struggle with big tasks, while large ones can waste fuel on small jobs.

Other things to consider are fuel use, maintenance, and spare part costs. Machines that use less fuel save money over time. Easy maintenance reduces downtime and keeps work going. Faster cycle times mean more work gets done, so choose parts that support this.

Tip: Look up manufacturer reputations and read reviews. This helps you find brands with durable and efficient parts.

Comparing OEM and Aftermarket Options

When buying excavator parts, you can pick OEM or aftermarket ones. Both have pros and cons, so knowing them helps you decide.

|

Aspect |

OEM Parts |

Aftermarket Parts |

|---|---|---|

|

Quality |

High quality, very durable |

Quality varies, not always reliable |

|

Cost |

30-50% more expensive |

Cheaper upfront |

|

Longevity |

Lasts longer |

May need replacing sooner |

|

Warranty |

Full backing for 1-2 years |

Limited coverage, depends on brand |

|

Safety Standards |

Meets strict rules |

Some may lack proper certifications |

|

Best Use Cases |

Reliable, safety-critical jobs |

Budget-friendly, older machines |

OEM parts are great for safety and long-term use. They meet strict rules and come with good warranties but cost more. Aftermarket parts are cheaper and good for older machines or quick fixes. Their quality varies, so pick trusted brands.

Note: For safety and reliability, OEM parts are best. For saving money, high-quality aftermarket parts work well.

Checking Quality Assurance and Compliance

Quality checks are vital when choosing excavator parts. Good suppliers test their parts to meet industry standards. Pick parts that pass these tests for better durability and performance.

Important tests include checking for defects, hardness, and surface finish. Strength tests ensure parts handle heavy loads without breaking. Advanced scans and magnetic tests find hidden flaws or cracks.

Trusted suppliers also track delivery times and material quality. They follow strict rules to ensure you get reliable parts.

Tip: Look for suppliers with ISO 9001 certification. This shows they focus on quality and reliability.

By choosing tested and certified parts, you reduce breakdown risks. This keeps your excavator running smoothly and efficiently.

Using Reviews and Recommendations

When picking excavator parts, reviews and advice can help. They share real experiences from users who tested the parts. By reading these, you can choose wisely and avoid wasting money.

Why Reviews Are Important

Reviews show what’s good or bad about parts. They explain how parts handle tough jobs, how long they last, and if they work as promised. Good reviews mean quality parts, while bad ones warn of problems.

Tip: Look for reviews with clear details like strength, fit, or setup. These are more useful than general opinions.

Types of Reviews to Look For

Reviews come in different forms. Each type gives unique insights:

-

Customer Reviews: Written by people who used the parts. They share practical tips about how well the parts work.

-

Expert Reviews: Industry experts test parts and give detailed feedback. Their reviews are reliable and thorough.

-

Video Reviews: Watching parts in action shows how they work and their quality.

Advice from Trusted People

Best Places to Get Excavator Parts

Approved Dealers and Distributors

Approved dealers are the most trustworthy for excavator parts. They work with manufacturers to provide genuine parts. These parts are made to fit your machine perfectly. This lowers the chance of problems and improves performance.

Another benefit is expert help. Dealers have staff who can advise you on the right parts. They also offer warranties, so you know the parts will last. If you want quality and reliability, choose approved dealers first.

Online Shops and Marketplaces

Online shops are a popular way to buy excavator parts. They are convenient and have many options. But you must check if the parts are real before buying. Look for sellers with good reviews and high ratings. Check product pictures to ensure they match trusted brands like Case. Shops with easy return policies are safer to use.

Before buying a lot, contact the seller to confirm the parts are real. This helps you avoid fake products. Online shops are great for comparing prices and finding rare parts, but research carefully.

Local Stores and Workshops

Local stores let you see the parts before buying. This ensures they meet your standards. Many workshops also install the parts for you, saving time. They often have parts for older or uncommon machines, which is helpful.

Building a good relationship with a local store can get you better deals. They may also give advice on maintenance and recommend the best parts. For quick repairs, local suppliers are usually the fastest choice.

Second-hand and Refurbished Parts

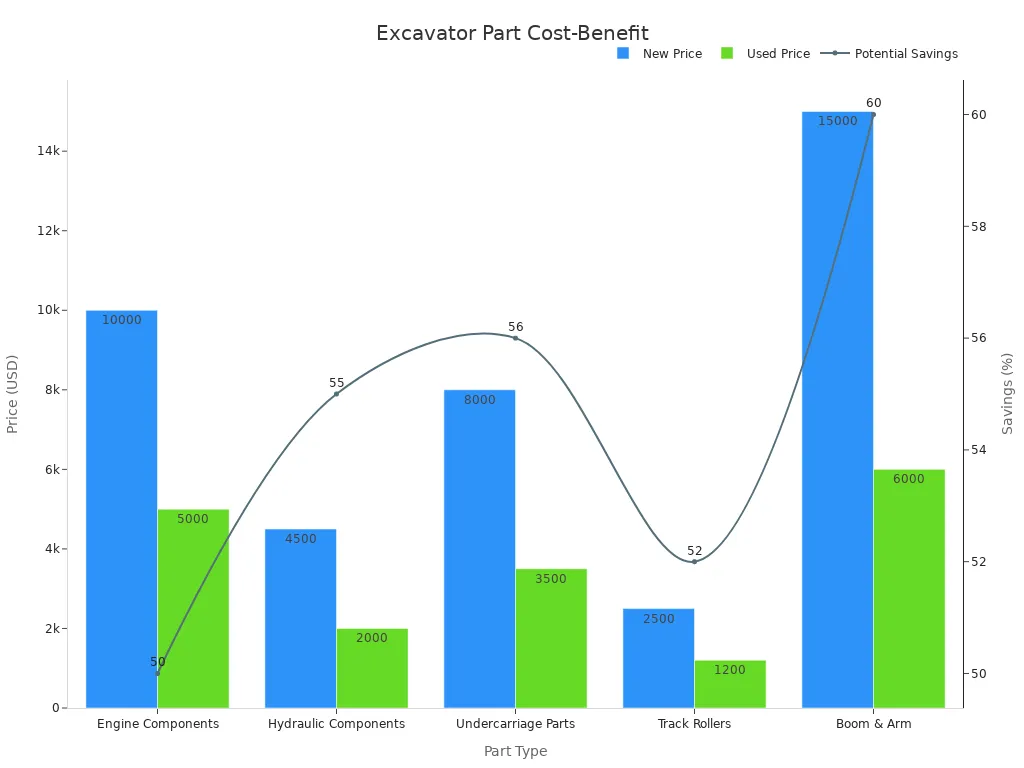

Used and refurbished excavator parts are a cheaper way to maintain machines. These parts save money and still work well if bought from trusted sellers. Choosing used parts helps cut costs without losing quality.

The main benefit of second-hand parts is their low price. Refurbished parts are checked and fixed to meet good standards. This makes them a reliable option for keeping your excavator running longer. For instance, refurbished engines or hydraulic pumps often work like new ones but cost much less.

The table below shows how much you can save with second-hand parts:

|

Part Type |

New Part Price |

Used Part Price |

Potential Savings |

|---|---|---|---|

|

Engine Components |

$10,000 |

$5,000 |

50% |

|

Hydraulic Components |

$4,500 |

$2,000 |

55% |

|

Undercarriage Parts |

$8,000 |

$3,500 |

56% |

|

Track Rollers |

$2,500 |

$1,200 |

52% |

|

Boom & Arm |

$15,000 |

$6,000 |

60% |

When buying second-hand parts, check their condition carefully. Look for rust, damage, or wear that might affect how they work. Trusted sellers often give warranties on refurbished parts, which adds extra security. Also, refurbished parts are better for the environment because they reduce waste and encourage recycling.

Tip: Make sure second-hand parts match your excavator model. This avoids problems and keeps your machine working well.

By using second-hand or refurbished parts, you save money, cut downtime, and help the environment. These parts are a smart choice for those who want to save money while keeping their machines efficient.

Buying strong and matching excavator parts keeps your machine safe and working well. Good parts last longer and break down less, saving you money over time. Knowing important parts like transmission and undercarriage helps you pick the right replacements. Many companies now upgrade old parts to newer ones for better work results.

|

Evidence Type |

Description |

|---|---|

|

Transmission Parts |

Move power efficiently; strong parts are needed for better performance. |

|

Undercarriage Parts |

Help the machine move; tough parts handle rough ground and are in high demand. |

|

Modernisation Demand |

Firms swap old parts for advanced ones to improve work speed and meet needs. |

Choosing good-quality parts from trusted sellers keeps your excavator dependable. This protects your money and ensures steady work, even in tough conditions.

FAQ

What are the benefits of using OEM excavator parts?

OEM parts fit your machine perfectly and meet strict standards. They are strong, reliable, and come with warranties. This lowers risks and saves money over time. They are ideal for tough jobs and safety-critical tasks.

How often should you replace excavator undercarriage parts?

Change undercarriage parts after 2,000 to 7,000 hours of use. Check them often to spot wear early. Problems like rust or misaligned tracks can shorten their life. Regular care keeps your machine working well and avoids costly repairs.

Can aftermarket parts match the quality of OEM parts?

Good aftermarket parts can be as reliable as OEM ones. They cost less and work well for older machines. Always check reviews and certifications to ensure they are safe and fit properly.

How do you identify the right part for your excavator?

Look in your machine’s manual for part details and numbers. Ask experts or sellers like YNF Machinery for advice. Giving exact information about your excavator helps you find the right part and avoid problems.

Are refurbished excavator parts a good option?

Refurbished parts are cheaper and still work well. Trusted sellers fix and test them to meet high standards. They are great for less demanding jobs and help reduce waste, making them a smart choice for saving money.

.jpg)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)