A representative of the company advised that WAM was their preferred supplier due to the quality of the product and the technical assistance provided when sizing the bin activators for the application.

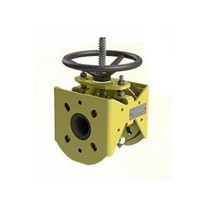

BA bin activators are devices of tapered conical shape that due to vibration facilitate material flow from hoppers or silos. They consist of a seamless carbon or stainless steel cone spun on sheet metal lathes, a seamless SINT engineering polymer seal with integrated top and bottom flange, suspensions for connection between bin activator and silo, as well as one or two electric vibrators.

To fit the BA bin activator, the silo cone has to be shorter than usual, leaving a wide outlet section. A flange supplied together with the bin activator is welded on the silo outlet on site.

Special suspensions and a seamless flanged SINT engineering polymer seal form a flexible connection between silo and bin activator.

One or two electric vibrators fitted to the unit generate vibration of the bin activator every time the feeding device beneath the silo is started for discharging material.

During operation the bin activator describes a gyratory movement which is transmitted to the material inside the silo. The result is smooth material flow through the bin activator outlet into the connected feeder.

BA bin activators are used in various industrial applications to facilitate discharging of powdery or granular materials from silos or hoppers.

The use of this equipment ensures optimum feeding of the material and causing 'mass flow' inside the silo, thus avoiding such phenomena as bridging or rat holing.

For more information, visit WAM Australia's website at www.wamaust.com.au.