Do you operate a temperature controlled warehouse?

Did you know, that by using ventilated stretch wrap that you can significantly reduce your electricity bills?

It's no secret that energy costs are continuing to rise. As a key yet unavoidable operating expense, businesses are seeking ways to reduce their electricity consumption and costs, but it's becoming more difficult due to many external factors beyond their control.

Switching to solar electricity and LED lighting is a great start. And if you operate a temperature controlled factory, you'll also want to reduce your refrigerating costs, which will take up a big chunk of your energy spend.

Choosing to use ventilated stretch wrap for your pallets of goods and fresh produce can be an easy and effective way in which to reduce those costs.

So, how can ventilated stretch wrap reduce electricity costs for cool rooms?

Breathable stretch wrap helps to keep the load ventilated, allowing cool air to easily flow into and around the pallet. Contents are cooled faster and more evenly, reducing freezing time. In this way, ventilated wrap can immediately impact your energy consumption, as opposed to conventional stretch wrap, which acts as an insulation for the load, increasing the cooling time required.

Checking the temperature of your cool room:

Typically, cool room operators keep the temperature lower than required so that the pallets which are wrapped with conventional film can be cooled adequately. A lower-than-required temperature becomes an unwanted necessity for cooling the centre of the pallet load to the required degree. This results in higher electricity costs. However, with a ventilated, breathable stretch wrap, free-flowing cold air can circulate more easily, cooling the center of the pallet load with lesser effort. The freezer temperature isn’t required to be kept as low, and can be maintained at energy-optimum levels.

Other uses for breathable ventilated stretch wrap:

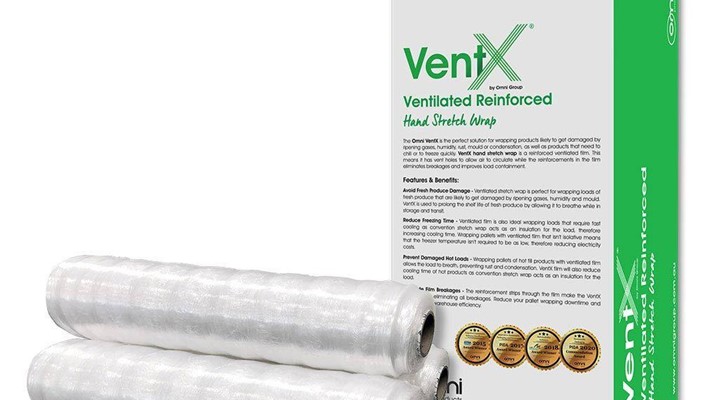

In addition to wrapping pallet loads that are to be refrigerated or frozen, ventilated stretch wrap can be used to wrap loads of fresh produce that may get damaged by ripening gases, humidity, mould or condensation. Ventilated stretch wrap is used to prolong the shelf life of fresh produce by allowing it to breathe while in storage and transit.

Engineered for strength and performance:

Omni VentX Stretch Wrap is a reinforced ventilated film. The ‘reinforcement strips’ run through the film making it tear-resistant, while wrapping the pallet loads. Without stretch film breakages, the pallet wrapping downtime is reduced. The additional reinforcement means it is also highly effective for load containment.