This approach works really well in most applications and Robotunits utilises this approach on all standard conveyors. There are however, a few circumstances where this approach is not reliable and other solutions need to be implemented. Conveyors with a width to length ratio of less than 1:2 for instance will not track properly with crowned rollers. Conveyors where the direction of travel changes should also not rely on crowning.

The clever solution – A conveyor with a tracking strip

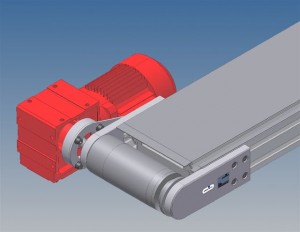

It is now possible to order belt conveyors from Robotunits where the belts themselves are fully guided. This is done via a tracking strip joined onto the underside of the belt, which in turn runs in the base extrusion T-slot and a location groove machined into the rollers.

This feature offers the opportunity to integrate standard belt conveyors into an automation solution, which up to now would have demanded the use of a modular belt conveyor. In most cases those would be substantially more expensive.

With clever and innovative solutions such as the fully tracked belt conveyors we are again able to help you save money. Fully guided conveyors can still be shipped within two working weeks, fully assembled!

-160x160-state_article-rel-cat.jpg)

-205x205.jpg)