AmbaFlex offers its customers the choice between highly standardised ‘off the shelf’ spiral conveyors, the so-called Pre-Defined Configuration, and customised spiral conveyor solutions. Solutions using predefined spirals have been configured and are available for almost all industries, being very economic and quick to deliver. Through the customized program, AmbaFlex offers a spiral conveyor for every application. Here AmbaFlex uses all of its 20 years of spiral conveyor expertise and proven technologies to solve even the most demanding applications.

A global manufacturer in prestige Chocolate confectionery had such a need to resolve an issue when upgrading a packing line. For the customer, if they could solve the issue, it meant saving substantial investments through changing the complete packing line layout.

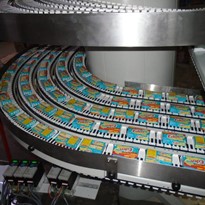

In a very space-restricted area, the confectioner needed to lower a double stream of packs down to two check weight checking scales. The horizontal distance between the two overhead feeding conveyors and the scales was less than 2 meters. However, the pitch between the feeding conveyors differed from that of the scales, so there was a need to create a spread in width. And on top of that, the scales were offset in the direction of travel. Another complicating factor was the handling of the products as the stand-up, circular shaped and unstable chocolate bar packs could not be allowed to tumble. A challenge of its own given high speeds. All together a challenging three dimensional issuethat needed to be resolved.

AmbaFlex focuses on offering customers a complete handling solution for complicated three dimensional challenges. The product range includes the SpiralVeyor® SVs series, the most compact spiral conveyor available in the market. This offers up to 50% space saving and is especially designed for highly demanding primary packing jobs. AmbaFlex’s SpiralConnect programme offers the option of a variety of connection possibilities at both ends of the Spiral. And by combining both, endless flexibility is achieved in the vertical and horizontal directions, making the most out of the available three dimensions. Our customers find it important that such a connection involves no additional internal transfers and so the Spiral Connect programme offers a one belt solution.

In this case, a SpiralVeyor® of the SVs series was chosen. The 140mm wide belt, with optional super flat friction topping, was combined with a short, but essential, connecting extension from the SpiralConnect programme. This connection created the small correction sideways and in height, and extends up to the start of the scale conveyor. The dual lane option offered the best space utilisation as two separate spirals proved not to be an option in this case. The endless, stainless steel B-style guides, with polished contact surfaces, is the final piece of this perfect primary packing solution.

The integration of this special customer configurator dual lane solution proved easy to implement. The unit came preassembled and tested and was plug and play. The critical transfers at both ends were also pre-tested in AmbaFlex’s test centre in Zwaag to avoid any delay during an overnight installation.

One more proof of AmbaFlex’s leading position in Spiral Conveyor solutions.