The Full Body Harness

A full body harness is one of the most crucial elements of someone’s personal protective equipment (PPE): of everything that employees use, they will interact most frequently with the harness, whether donning, adjusting or inspecting it. However, it’s not enough for the employer to simply ensure that staff wear the harnesses when working. Often, harnesses can be extremely uncomfortable if they are not worn correctly or adjusted properly, and this can put the fall arrest effectiveness at risk for the user. In addition, proper inspections should highlight in advance those fall protection harnesses that can no longer be used due to wear and tear.

Harness Evolution

Harnesses have come a long way since the linesman’s ‘body belt’, worn in the early 1900s around users’ waists for pole climbing. These forerunners of today’s full body harnesses were at best better than nothing, only providing some protection to arrest falls if the worker happened to fall ‘correctly’. The belts offered no impact or shock protection from impact forces to the body. Worse still, they rarely fitted correctly, meaning that workers often fell out of the belts which were too loose.

Accidents led to the development of the first full body harness, designed initially with the objective of better distributing fall arrest forces and minimising the chance of the worker falling out of the system. Developed in the 1940s and modeled on the military parachute harness, this harness did distribute fall arrest forces more evenly but still fell way short of perfect. The bulky and heavy materials used in its construction proved to be very cumbersome and hard to don and wear, leading to a lack of widespread use.

In time, developments moved on to triangular and X-fit style harnesses. These were easier to don, as they fell in place by simply grasping the dorsal D-ring. The first harness with comfortable features such as soft edging and padding was not developed until 2001. Designed in the mould of a recreational harness, this comfort harness used durable materials and included features such as five points of adjustment, a ‘stand-up’ dorsal D ring and quick connect buckles to aid donning and achieve a good fit.

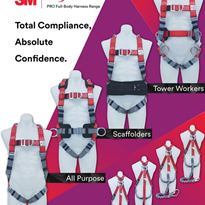

Today’s height safey harnesses have evolved to include features designed for specific industries. As long as the harness is comfortable and does not restrict a worker’s movement, he will choose to wear it in order to protect his safety. This is particularly important in companies where there is not a large safety culture and no clear procedures for operator training. If a worker feels that he cannot do his job as well when encumbered by a body harness then he will not wear it unless he is forced to.

The Right Fit

Only a properly fitted harness will ensure the right distribution of fall arrest forces to the appropriate regions of the body. In the event of a fall, if the harness is too loose, the uneven distribution of forces throughout the body could exert dangerous pressure on certain areas. Movement of the sub-pelvic strap can lead to serious injury for male workers, and if the chest strap is loose it can cause the shoulder straps to fall of the shoulders. A fall protection harness that is not not correctly adjusted can cuase a choking hazard in the event of a fall. Any loose straps could also prove hazardous if caught on moving or heavy equipment.

Harnesses that are too tight also lead to the improper distribution of fall arrest forces in the event of a fall, as well as extreme discomfort and loss of circulation. As a general rule, if the user is able to just make a fist in between his body and one of the harness straps when wearing the harness, then it is a snug and proper fit.

Top 5 Most Important Full Body Harness Features

1. Comfort

It’s all very well for a harness to meet Australian Standards and have every certification mark going. However, these safety components are useless if the harness doesn’t get worn, or is worn incorrectly. Some harnesses have to be worn for up to 12 hours per day, so comfort is paramount. Webbing and edging should be soft to avoid chafing the skin, and in moist environments anti-absorbent and water-repellant webbing can help to keep the worker cool and dry in moist environments. Padding around the shoulder straps and leg areas is essential.

2. Adjustability

The harness will not be comfortable if it doesn’t fit properly.

• There should be multiple points of adjustment, in order to ensure the worker can properly fit the harness to his own body. Harnesses with 5 points of adjustment on the chest, shoulder and leg straps are readily available in Australia.

• Adjustment points should be maintained and secure. This is less easy to find in a full body harness, as often adjustments are required throughout the day. However, today harnesses are available with torso adjusters and quick-connect buckles that lock without loosening, even when worn for extended periods.

3. Ease of donning and use

Features to look for to maximise ease of donning and use include quick-connect buckles and stand-up dorsal D-rings. It’s also easier to put on harnesses that maintain their shape so they don’t get tangled.

4. Durability

A good quality harness will stand up to any tough conditions that it’s being used in, making the investment in premium harnesses worthwhile. Features such as pads over high-wear areas like shoulder straps help to reduce them from wearing out. Other durability features include rigid belt loops, corrosion-resistant hardware and abrasion-resistant webbing.

5. Customisation

Different harnesses suit different work situations, so it’s important to select the right harness to complement the task in hand. If the harness is treated like a necessary tool of the trade rather than an encumbrance then the worker will be far more inclined to wear it. There are several customised features available on the market, such as areas to attach a tool pouch, suspension trauma straps and seat slings.

Harness fitting and inspection

As well as ensuring the right harness selection and fit, it’s vital that the equipment is properly inspected before each use. An inspection program should be developed by a competent and trained person at least 6-monthly or less depending on the working conditions during use. Each separate inspection should incorporate 5 distinct elements:

1. Hardware

All hardware including keepers, grommets, buckles, the back pad and D-rings should be checked to make sure there are no sharp edges, cracks, corrosion or worn parts. Buckles, including any springs and metal rollers need to work freely. If any hardware is coated in PVC, it must not be damaged in any way in order to maintain non-conductivity. Any proper markings such as ratings and certification marks should be in place.

2. Webbing Inspection

Straps and belts need to be free of any signs of wear and tear, fraying, abrasion or ripped stitches, and also mould, stains or discolouration. It’s important to check the manufacturer’s instruction manual for the number of stitches permitted in a stitch pattern, as these can differ from harness to harness. The harness should be removed from service if any of these signs are present.

3. Label inspection

All required labels need to be present and legible.

4. Subsystem Components

Each system component or subsystem should be inspected according to the manufacturer’s instructions.

5. Record keeping

The maintenance and inspection results should be recorded clearly on a record card or history sheet, including dates and details of all previous inspections and also the date first used.

The manufacturer’s instruction manual also includes information on how to adjust and don the harness. Capital Safety has developed instructional posters on how to properly don and inspect a harness, along with inspection and maintenance guidelines and checklists. These tools are available at no cost from the company’s website at www.capitalsafety.com.au.

In summary, it’s not enough just to make full body harnesses safe. Employers and workers need to keep abreast of improvements in the fall protection industry to ensure the best possible customisation for harness users. Up-front investment in a premium harness will help to reduce the overall cost of any company’s fall protection program, but the ultimate cost of not wearing the correct harness could be far more than financial.

For further information on issues contained within this article or any other, please contact Capital Safety on 1800 245 002 (AUS) 0800 212 505 (NZ) or visit www.capitalsafety.com.au.