A soup production facility was looking to replace their unreliable surface aerators to save maintenance costs and improve efficiency at their facility. The facility environmental engineer contacted Hydro Innovations for a solution. Hydro Innovations suggested Venturi Aeration. The soup manufacturer greatly improved their efficiency with Venturi Aeration.

Venturi Aeration line of wastewater treatment products was introduced to Australia after their successful application by food processors in the USA and Europe. They have experienced great success in the Australian market, especially the food process market, where Venturi Aerators treat the wastewater.

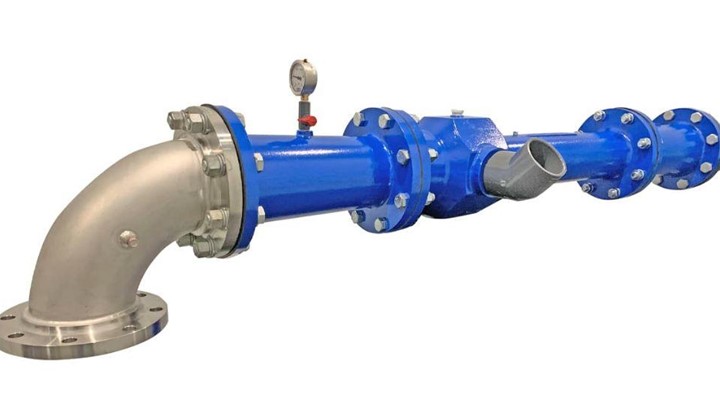

The Venturi Aeration aerators are used in conjunction with Gorman-Rupp pumps and can be mounted on the banks of basins and lagoons instead of needing to be installed within them.

The soup production facility was happy with their results when they converted to a Venturi Aerator. The installation resulted in annual operating cost savings of more than $112, 000.

The system has improved the overall EQ tank performance to produce clearer effluent, controlling odours, settling solids, cooling the water, and hydrolysing fats, oils, and greases causing them to float for better removal efficiency.

The former system was to add dissolved oxygen to mix and equalise the contents in the EQ tank using submerged aerators. The addition of the dissolved oxygen would cause fats, oils and grease to float so they would not be discharged with the plant’s effluent into the publicly owned treatment works.

The submerged aerators were also supposed to provide cooling of the influent process washdown water (at around 40°C).

The aerators had been in operation for several years and were not achieving the desired conditioning objectives. Further, whenever one of the submersible pumps plugged or failed, the company had to rent a crane to remove the pump for repairs and then had to use the crane for removal, repair and to reinstall the repaired pump at additional costs on each occurrence.

As one or more of the submerged pumps was failing at least once if not twice a year, the company began to look for more viable aeration, mixing, and equalisation solution to keep them in compliance.

The facility environmental engineer decided to replace the existing aerators with a Venturi Aeration Model VA-1400 aerator and a T8 Gorman-Rupp pump. The venturi aerator was designed to handle 82L/s. This allows the contents of the EQ tank to be recirculated four times during a 24-hour period, achieving greater oxygen transfer and better mixing and equalisation.

With better circulation and cooling in the EQ tank the fats, oils, and grease is floated for separation and treatment and is not being discharged with the effluent to the local treatment works, reducing surcharges.

The plant was able to achieve a $6000 annual energy cost reduction, an $89,000 annual reduction in chemical costs, a $12,000 annual reduction in non-compliance charges, and further maintenance cost reductions.

The facility environmental manager now has a system that allows him to achieve his discharge permit parameters and he has less concern over maintenance issues and costs. The soup manufacturer improved their efficiency with Venturi Aeration and will continue to experience fantastic results.