At Toyota Material Handling, we know how important it is to keep your Huski skid steer loader on site working for you.

That's why after evaluating available technology alternatives, we purposefully decided to retain the reliability of solid-state electronics on the Toyota Huski 5SDK skid steer loader range in order to minimise maintenance requirements and reduce possible machine downtime.

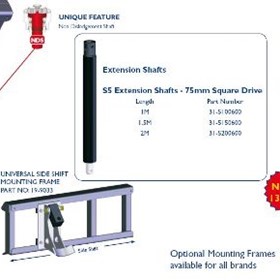

SOME OTHER FEATURES ON OUR HUSKI 5SDK SKID STEER LOADER RANGE INCLUDE:

- All models use large-capacity and high pressure resistant HST motors

- The hydraulic fluid capacity has increased to maintain fluid temperature at optimum levels

- Re-positioning of the oil cooler improves cooling performance

- Pressure reduction rings for each of the lift and dump cylinders absorb impact when digging. This protects the gasket seal and improves reliability with respect to oil leaks.

- Wedge-shaped pins that move vertically instead of horizontally secure the bucket in place and reduce noise during bucket operation

(ISO hitch only) - Multiple safety interlock systems

Skid Steers Loaders for Australian Conditions -

Australia has some of the most rugged working conditions in the world, which is why Toyota Material Handling chose to develop and test the Huski 5SDK skid steer loader range here. This truly means the Huski 5SDK is engineered to handle Australian conditions.

- Tested in varying conditions, from sub zero to high ambient temperatures

- Air conditioning available as an option to keep an enclosed cabin at a constant and comfortable temperature. An external air-intake port and air filter prevent dust from entering the cabin

- An alkyd paint has been replaced by a urethane paint for greater protection against rust and to reduce fading.

-280x280-state_7.jpg)