Below is basic guide to help you understand the terminology that is most commonly used in the warehouse racking industry to describe pallet racking components.

Some of the most commonly used expressions include: pallet racks, selective pallet racking, heavy duty racking, warehouse racking.

Selective Pallet Racking

Selective pallet racking is the most popular pallet racking system. It is called “selective” because it allows a pallet to be selected from the racking system without having to move any other pallets. Selective pallet racking systems are the most cost effective racking system available, based on cost-per-pallet space.

Upright

Upright refers to the vertical posts within a pallet racking frame. They vary in heights and widths, depending on the overall bay load and pallet weight. 2 uprights joined together with bracing form an ‘Upright Frame’

Frame

Frames can be also referred to as an upright frame. A frame is made up of 2 upright posts and cross bracing. The capacity of the frames changes with the height and bracing pattern. The depth of a pallet racking frame will change depending on the depth of your pallets and product.

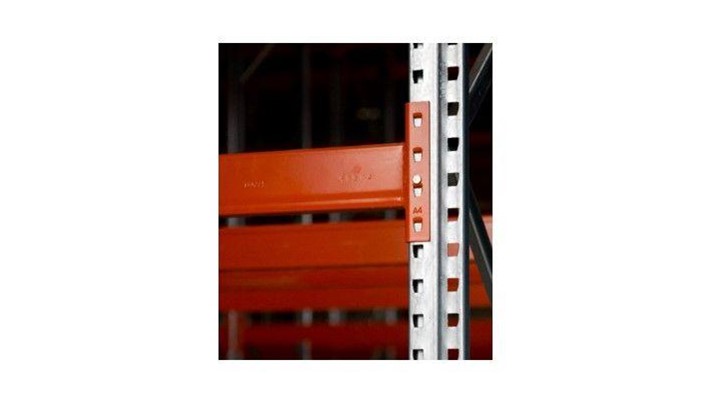

Beam

The horizontal piece or bar joining the frames together is called the pallet racking beam. Pallet racking beams slot into the holes in the upright frames. They are made in many different lengths and widths depending on the number of pallets being stored and the weight of the products. Many of our customers also refer to these as ‘rails’.

-205x205.jpg)