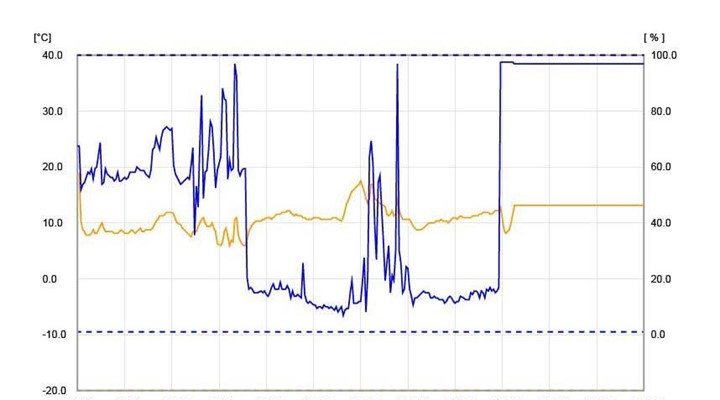

Let’s look at data log reports for a large food processing plant. The two graphs below are reports showing the humidity and temperature levels and fluctuations within an ante chamber adjacent to a blast freezer.

Client needed the 60 to 80% fluxing humidity in their blast freezer to be brought down to 20% relative humidity (RH) and remain at 20% RH.

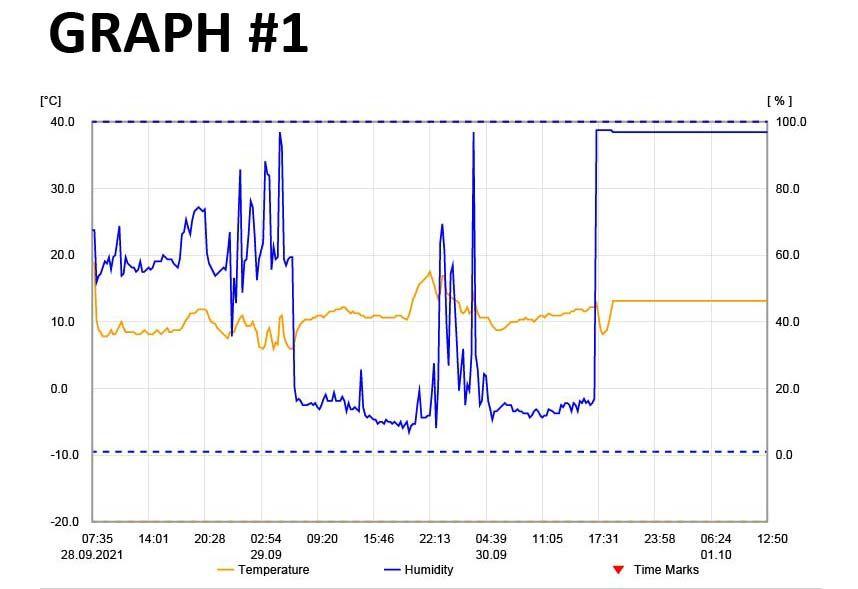

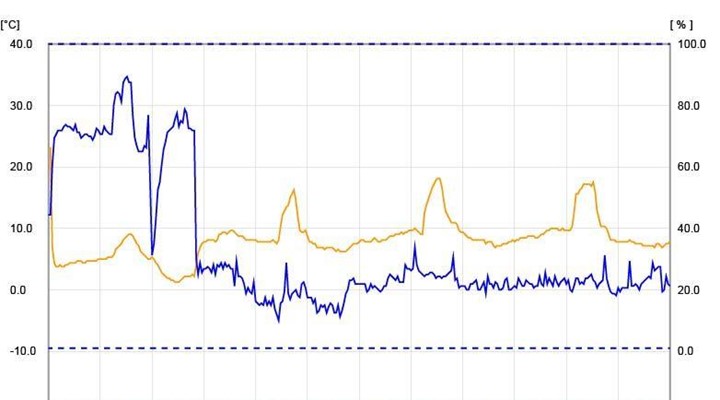

Look at GRAPH #1

This data is over a three-day period. This process freezer has automatic doors, strip curtains and a dehumidifier installed. However… door opening times were sometimes longer than necessary and strip curtains were pulled up and left up.

As you can see the humidity is all over the place (blue line). And condensation, fog and ice began to creep back into the storage area.

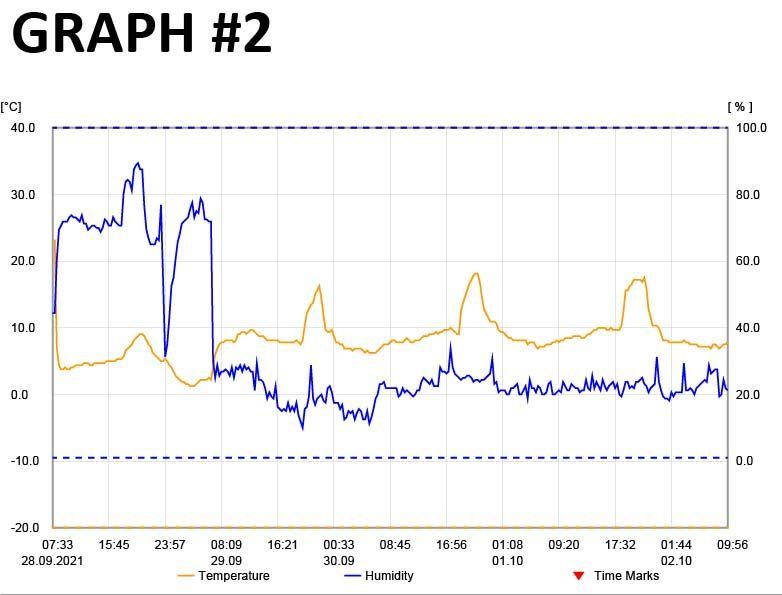

Look at GRAPH #2

Same ante chamber – data over a four-day period. For the purpose of this report, we turned off the dehumidifier and turned it back on again. This allows us to show you the difference in humidity levels once a commissioned dehumidifier is up and running.

Once the dehumidifier was running again, employees were mindful, so door opening times were reduced and strip curtains were not swung up.

As you can see the 20% humidity set point is achieved and maintained

Solution Achieved

After installation and commissioning of a dehumidifier a far more consistent humidity level is reached and maintained. Meaning fog and ice build-up were dramatically reduced along with energy consumption and production downtime.

Why Does Ice Build Up Happen?

Ice build-up is caused when moist air enters the cold store. Sometimes there can be thin layers of ice which has the appearance of snow. When the moist air comes into contact with cold surfaces such as floors, walls and evaporator coils, the water vapour in the air condenses to form water and then freezes to form ice.

Moisture typically enters the cold store or freezer during door opening times. As the doors open warmer, more moist air is naturally drawn into the cold store, which in turn causes fog, condensation, and ice.

Three Ways to Reduce Ice in Cold Stores:

1. LIMIT NUMBER OF SECONDS DOOR IS OPENED EACH TIME.

Do not underestimate how much moisture enters the cold store every time the doors are opened. If you can reduce the number of seconds the door is open, you will significantly reduce the amount of moist air entering. Rapid doors on timers are a good idea. Or put in the practise of the shutting the door straight after you enter. Do not leave the cold store door open as you are packing or looking for product!

It only takes 30 seconds of a door being left open to the ambient air for ice to start to grow on an evaporator fan.

2. INSTALL PLASTIC STRIP CURTAINS.

Plastic curtains are a good way to reduce the amount of air that enters the cold store during door opening times. The curtains act as a barrier so that it is harder for the moist air to get into the cold store. However, moist air will still get into the cold store through the gaps and when a forklift is running through the curtains.

3. USE A DEHUMIDIFIER TO ENSURE YOUR COLD STORE IS KEPT DRY.

The best way to ensure your cold store is kept as dry as possible and for ice build-up to be dramatically reduced is to install a dehumidifier. It dehumidifies the air as it enters the cold store. As the doors open, it captures the moist air, dehumidifies it, and supplies dry, low dew point air at the entry doors. This dry air is drawn into the cold store when the doors open and circulates freely across the floor to keep it dry.

Key Facts:

- A TFT Desiccant Dehumidifier can be placed inside the cold store. It has been specially designed to withstand the tough, cold environment within cold stores, ensuring the unit runs reliably and efficiently.

- Even when the doors are closed, the dehumidifier will still sublimate ice and snow inside the cold store, in comparison to an airlock, which is running during the logistic time.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)