These switches are used in a variety of industrial applications, including manufacturing, transportation, and aerospace, among others. In this article, we will discuss the function, types, and applications of pneumatic pressure switches.

Function of Pneumatic Pressure Switches

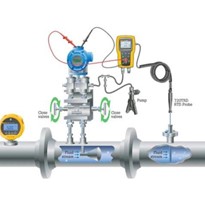

Pneumatic pressure switches are used to monitor and control air pressure in a system. When the pressure in the system reaches a certain point, the switch will activate and trigger a response, such as turning on a compressor or opening a valve. Pressure switches are designed to detect both high and low pressures, and can be adjusted to trigger at a specific pressure point.

Types of Pneumatic Pressure Switches

There are two main types of pneumatic pressure switches: electromechanical and solid-state.

Electromechanical pressure switches use a mechanical switch to detect pressure changes. These switches have a diaphragm that flexes as the air pressure changes. When the pressure reaches a certain point, the diaphragm will activate a mechanical switch that triggers a response in the system.

Solid-state pressure switches use electronic sensors to detect pressure changes. These switches are more precise and reliable than electromechanical switches, and can be used in a wider range of applications. Solid-state switches can also be programmed to trigger at specific pressure points, and can be integrated with other electronic systems to provide more advanced control over the pneumatic system.

Applications of Pneumatic Pressure Switches

Pneumatic pressure switches are used in a variety of industrial applications, including:

- Manufacturing: Pneumatic pressure switches are used in manufacturing equipment to control the flow of air through pneumatic cylinders, valves, and other components. They can also be used to monitor the pressure in pneumatic tools, such as air compressors and impact wrenches.

- Transportation: Pneumatic pressure switches are used in transportation systems to monitor air pressure in tires and brake systems. They can also be used in air suspension systems to control the height and stiffness of the suspension.

- Aerospace: Pneumatic pressure switches are used in aircraft systems to monitor the pressure in pneumatic components, such as landing gear and hydraulic systems.

- Medical: Pneumatic pressure switches are used in medical equipment to control the flow of air in respiratory equipment, such as ventilators and oxygen concentrators.

Conclusion

Pneumatic pressure switches are essential components in many industrial applications. They provide a reliable and precise way to monitor and control air pressure in pneumatic systems, and can be used in a wide range of applications, from manufacturing to transportation to aerospace. Whether you need to control the pressure in a pneumatic tool or monitor the pressure in an aircraft system, pneumatic pressure switches are an essential tool for maintaining efficient and safe operation.