?Using 3D printing, Mideco is able to reduce the lead time on prototype iterations substantially, getting more work done in less time and with less cost.

Company Overview:

Mideco, an Australian-owned company established in 1950, specializes in providing dust control products and solutions for mines, quarries, and various commercial environments. With over 70 years of expertise in dust collection projects, Mideco has a strong track record in solving complex dust collection and extraction system challenges.

The Challenge:

Mideco faced the challenge of optimizing its product development process, which involved designing intricate parts, prototyping, and collaborating with suppliers. The traditional method was time-consuming and expensive.

The Solution:

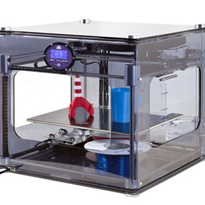

Raise3D Pro 3+ 3D Printer Mideco adopted the Raise3D Pro 3+ 3D printer to streamline their product development process. Here are the key reasons why this 3D printer proved to be a game-changer:

- Precision and Accuracy: The Raise3D Pro 3+ exhibited exceptional precision and the ability to produce highly detailed prints. This precision allowed Mideco to bring intricate designs to life with incredible accuracy, significantly benefiting their product development process

- Reliability: The Pro 3+ demonstrated remarkable reliability, consistently delivering exceptional results during long and complex print jobs. Its robust construction and stable performance earned the trust of Mideco's team

Improved Product Development Process:

Before implementing the Raise3D Pro 3+, Mideco's product development process involved designing a 3D model using Inventor, sending the design to a supplier to create a sample, and dealing with extended lead times and high labor costs.

With the Raise3D Pro 3+, Mideco streamlined their process:

- Design: Using Inventor, they created 3D models of desired parts

- 3D Printing: The 3D models were imported into IdeaMaker slicing software and printed using the Raise3D Pro 3+

Results:

The introduction of 3D printing with the Raise3D Pro 3+ brought about significant improvements:

- Reduced Lead Times: Prototyping and part production lead times were significantly reduced, resulting in cost savings throughout the design-to-production process

- Labor Savings: Mideco reduced labor costs by 50% during the production process, making their operations more efficient and cost-effective

- Production Cost Reduction: Depending on the size of the part, production costs were reduced by approximately 30%, further enhancing their competitiveness in the market

Future Possibilities:

Professionals in environmental engineering and sustainability can explore 3D printing applications related to recycling and sustainable materials. Some are already utilizing 3D printing to recycle plastic waste into usable products, aligning with the principles of environmental sustainability. In conclusion, the adoption of the Raise3D Pro 3+ 3D printer has revolutionized Mideco's product development process, leading to increased efficiency, cost savings, and enhanced precision. This success story showcases the transformative potential of 3D printing technology in various industries, including environmental engineering and sustainability.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)