RAM sought to upgrade its circulating coin blank handling and finished coin ware- housing with a state of the art system incorporating leading edge technology.

RAM required an organisation that could provide innovative engineering design and also undertake the manufacture and installation of the materials handling and warehousing system (MHWS).

Required project outcomes included: increased product security; improved OHS; improved materials flow; providing high levels of process automation and process management; and increasing the Mint's appeal as a Canberra tourist destination.

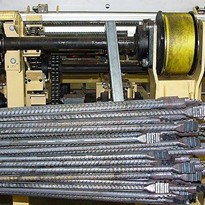

As the successful tender, Australis Engineering's design solution provided the following benefits: world's first coin Vision Counting System (VCS), a Manufacture Execution System (MES) to manage the entire coin production process; use of robotics to minimise manual handling and increase production output, fully integrated materials handling and warehousing solution, inclusive of special purpose roller conveyors.

The Result

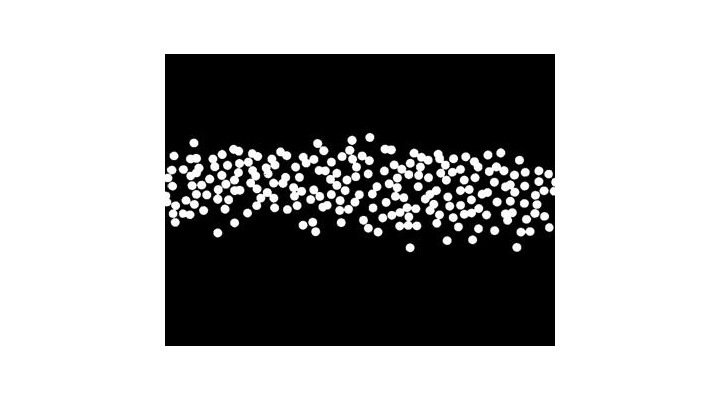

Beneficial outcomes of the Australis Engineering design include: whole of system integration using automation and best practice materials handling applications; total system output of over 2.2 million coins/ day with peak rates in excess of 8,600 coins/ minute; VCS capable of counting coins at rates exceeding 22,000 coins/ minute and accuracies over 99.9 per cent; AGVs to reduce manual lifting, improve throughput and OHS; industrial robotics to lift and decant large drums of coins and improve OHS; and design, manufacture and installation of belt conveyors, labellers, warehousing and bucket elevators.

Innovation

A key element has been the design, testing, manufacture and installation of a world's first, Vision Counting System (VCS) for coins. The VCS is a high-speed coin counter in a mass flow situation, allowing for elevated speeds and high throughput counting of up to 22,000 coins per minute. The system is designed to be virtually touch free so there is little chance of jams or blockages, resulting in a highly reliable system achieving over 99.9 per cent accuracy in production (depending on denomination).

The VCS has potential in other coin handling environments and for the pharmaceutical industry for tablet production facilities.

- Suppliers

- New to IndustrySearch? Book a Demo

- Advertise with us

- Login

- Email Marketing

- Buyers

- Get Quotes

- Articles & Ideas

- Login

- Subscribe to newsletter

- My Details

- Get Quotes

- Automation & Control

- Automotive Workshop Equipment

- Commercial Cleaning Equipment & Supplies

- Construction Equipment & Heavy Machinery

- Conveyor Systems & Components

- Electrical & Power Generation Equipment

- Electronic Components

- Farming & Agriculture

- Food & Beverage Processing

- Forklifts & Forklift Attachments

- Hydraulic & Pneumatic Equipment

- Industrial Materials, Tools & Components

- Industrial Pumps

- IT Hardware & Industrial Computing

- IT Software & Applications

- Laboratory Equipment & Instruments

- Manufacturing & Industrial Equipment

- Material Handling & Lifting Equipment

- Metalworking & Machining

- Mining Equipment & Machinery

- Packaging & Labelling Machinery

- Pallet Handling Equipment

- Personal Protective Equipment

- Security & Surveillance

- Test & Measurement

- Transport & Logistic Equipment

- Warehouse Storage, Shelving & Racking

- Waste Treatment & Environmental Management

- Welding Machines & Accessories

- Woodworking & Joinery Machines

- Workplace Equipment

- Workplace Safety Equipment

- Get Quotes

- Automation & Control

- Automotive Workshop Equipment

- Commercial Cleaning Equipment & Supplies

- Construction Equipment & Heavy Machinery

- Conveyor Systems & Components

- Electrical & Power Generation Equipment

- Electronic Components

- Farming & Agriculture

- Food & Beverage Processing

- Forklifts & Forklift Attachments

- Hydraulic & Pneumatic Equipment

- Industrial Materials, Tools & Components

- Industrial Pumps

- IT Hardware & Industrial Computing

- IT Software & Applications

- Laboratory Equipment & Instruments

- Manufacturing & Industrial Equipment

- Material Handling & Lifting Equipment

- Metalworking & Machining

- Mining Equipment & Machinery

- Packaging & Labelling Machinery

- Pallet Handling Equipment

- Personal Protective Equipment

- Security & Surveillance

- Test & Measurement

- Transport & Logistic Equipment

- Warehouse Storage, Shelving & Racking

- Waste Treatment & Environmental Management

- Welding Machines & Accessories

- Woodworking & Joinery Machines

- Workplace Equipment

- Workplace Safety Equipment

Trusted by 1,000,000+ Australian industrial buyers

Buyers

- Discover products & solutions

- Login

- Subscribe To Newsletter

- Browse All Products

- Read Articles

Suppliers

Advertise

- Promote your products & solutions

- New to IndustrySearch? Book a Demo

- Login / Forgot Password

- Advertise Your Products

- Success Stories

- Email Marketing

- Suppliers

- Advertise with us

- Login

- Email Marketing

- Buyers

- Get Quotes

- Articles & Ideas

- Login

- Subscribe to newsletter

- My Details

Get Quotes

- Automation & Control

- Automotive Workshop Equipment

- Commercial Cleaning Equipment & Supplies

- Construction Equipment & Heavy Machinery

- Conveyor Systems & Components

- Electrical & Power Generation Equipment

- Electronic Components

- Farming & Agriculture

- Food & Beverage Processing

- Forklifts & Forklift Attachments

- Hydraulic & Pneumatic Equipment

- Industrial Materials, Tools & Components

- Industrial Pumps

- IT Hardware & Industrial Computing

- IT Software & Applications

- Laboratory Equipment & Instruments

- Manufacturing & Industrial Equipment

- Material Handling & Lifting Equipment

- Metalworking & Machining

- Mining Equipment & Machinery

- Packaging & Labelling Machinery

- Pallet Handling Equipment

- Personal Protective Equipment

- Security & Surveillance

- Test & Measurement

- Transport & Logistic Equipment

- Warehouse Storage, Shelving & Racking

- Waste Treatment & Environmental Management

- Welding Machines & Accessories

- Woodworking & Joinery Machines

- Workplace Equipment

- Workplace Safety Equipment

Get Quotes

- Automation & Control

- Automotive Workshop Equipment

- Commercial Cleaning Equipment & Supplies

- Construction Equipment & Heavy Machinery

- Conveyor Systems & Components

- Electrical & Power Generation Equipment

- Electronic Components

- Farming & Agriculture

- Food & Beverage Processing

- Forklifts & Forklift Attachments

- Hydraulic & Pneumatic Equipment

- Industrial Materials, Tools & Components

- Industrial Pumps

- IT Hardware & Industrial Computing

- IT Software & Applications

- Laboratory Equipment & Instruments

- Manufacturing & Industrial Equipment

- Material Handling & Lifting Equipment

- Metalworking & Machining

- Mining Equipment & Machinery

- Packaging & Labelling Machinery

- Pallet Handling Equipment

- Personal Protective Equipment

- Security & Surveillance

- Test & Measurement

- Transport & Logistic Equipment

- Warehouse Storage, Shelving & Racking

- Waste Treatment & Environmental Management

- Welding Machines & Accessories

- Woodworking & Joinery Machines

- Workplace Equipment

- Workplace Safety Equipment

Trusted by 1,000,000+ Australian industrial buyers