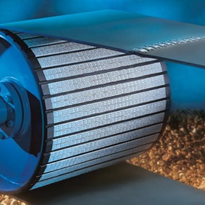

After assessing their application and a number of possible solutions, it was decided that the most effective action to take was to install a high intensity, rare earth magnet pulley. The company had an existing head pulley available so they sent it to MSA for the addition of their special ‘magnetic pulley lagging’.

This system causes no disruption to the process line, but instead of dropping contaminates into the same bin as the clean material, the pulley carries the contaminates underneath the conveyer belt and drops them off into separate bin underneath the head pulley.

This was met with high praise from Managing Director Peter Smith, who says "We recently needed a Magnetic Pulley with a very quick turnaround. When we started making enquiries, many companies couldn't make one or import one in less than a month. We made contact with MSA Magnetics and couldn’t believe the difference! They discussed the situation with us and gained an understanding of what we needed to do. We were able to make a simple Pulley and ship to MSA Magnetics overnight. They had promised a 3-day turnaround to convert the Pulley to a Magnetic Pulley… we had it back on a truck within 24 hrs! I have no hesitation in recommending MSA for their high level of expert and professional assistance and engineering, quality workmanship and most of all, exceptional service".

MSA provides complete new magnetic head pulley solutions OR magnetic lagging upgrades to your existing pulleys, any width and any diameter above 150mm.

For more information view our product here, or contact our friendly team today.

-720x400.jpg)

-720x400.jpg)

-720x400.jpg)

-205x205.jpg)

(1)-205x205.jpg)