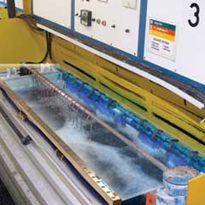

Their set-up (shown in the photo) had been working well until they increased the speed. The position of each Super Air Knife from top to bottom was correct. (This is recommended for removing water in a counter-flow direction when the bottles are traveling from the right side of the photo to the left side). However, as soon as they cranked up the speed, the bottles were wet, leaving lots of droplet marks that could be seen when they dried. This made the bottle appearance unacceptable.

The Solution:

The company modified the blowing direction of the Super Air Knives to optimise the efficiency. Originally, the airstreams of each Super Air Knife were aimed directly at each other - a high likelihood of splattering water all over. Now, the airstreams are directed downward toward the center of the conveyor. Now, the airstream wipes the water down the bottle surface, giving each bottle more contact time with the airflow. They are able to increase the conveyor speed and throughput as needed.

Editor's Comments:

This application goes to show that positioning can make all the difference in performance. It is worth mentioning that if you have a conveyor that transports a variety of products, the Model 9060 Universal Air Knife Mounting System to go with the Super Air Knives can prove quite useful. WIth a quick turn of the mounting system knobs, the correct angle of the Super Air Knife can be set to an optimal position.

-720x400.jpg)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)