Leveraging our two decades experience manufacturing laser diodes and laser amplifier modules, CEO is the only laser manufacturer offering commercially available Joule class all diode-pumped laser systems.

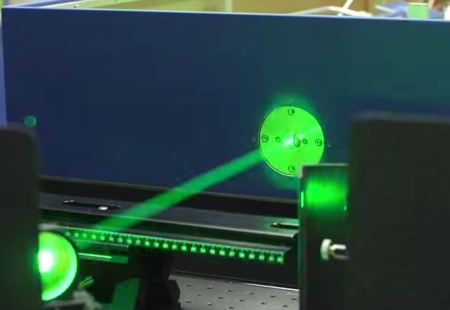

Utilising our PowerPULSE™ laser amplifier technology, we've developed a set of design standards for high energy DPSS laser systems. Starting with the customer's desired final beam characteristics and a given set of pumping conditions, we model the entire laser system, beginning with the final amplifier stage. We computationally work our way backwards through each amplifier stage until an energy level suitable for a single mode oscillator is achieved. We then choose a seed laser appropriate for the entire laser system.

Our laser scientists and engineers apply field proven design rules to each amplifier stage to produce a system that maximises spatial and temporal performance, while minimising cost per Joule of stored energy. By using only the inner 80 per cent of each laser rod, each amplifier stage minimises beam aliasing, beam clipping, and maximises gain uniformity. Utilising data collected over many years of laser amplifier manufacturing, we have determined that our modules store about 30 per cent of the pump energy. With this data we are able to minimise diode bar count, maximise energy extraction, and ensure that we stay below the damage limits of the optical coatings within the laser system.

We optimise each system by utilising our computational models, in concert, with our reconfigurable COTS laser amplifiers. This design approach produces high energy laser systems that meet the output requirements of our industrial and scientific customers.