Tucked away in a hidden enclave on Sydney’s North Shore is a private golf course. The golf course was crafted in 1926. The golf club is certified as an Audubon Society Cooperative Sanctuary for outstanding environmental management, and it harbours abundant birdlife. The course greenkeeping and management use cutting-edge water management systems [such as nanobubble technologies] and conduct their affairs in an environmentally friendly and reputable way.

The problem?

The golf course did however have a water issue they needed to tackle. A long narrow dam of theirs in the base of a gorge suffered from low dissolved oxygen [DO] and destratification. The low DO causing unwanted odours and poor water quality for use on the course.

The Solution

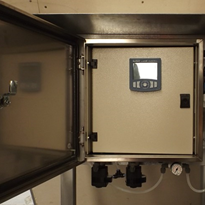

A consultancy firm contacted Hydro Innovations on behalf of the golf course and inquired about Venturi Aerators. Venturi Aerators are mounted on the banks of dams or lagoons, ensuring easy access for safe maintenance.

How do Venturi Aerators work?

They require a pump to deliver flow to the inlet nozzle [under pressure], where an increase in velocity uses the Venturi principle to draw in atmospheric air, mix it with the water, and discharge it saturated with DO into the dam. Venturi-Aerators are very efficient at delivering DO, but because the suction and discharge of the system can be located at any depth within the dam, destratification issues could also be dealt with.

What was installed?

Two pumps were installed to deliver flow to two 4″ Venturi-Aerators, which were set up to deliver 11.8kg of DO per hour per unit.

The results? …. They were great!

After running the units for a few weeks, Oxidation Reduction Potential [ORP] and DO readings were taken. The ORP went from -125mV at a 3m depth to + 130mV. The DO levels increased from less than 0.3mg/L to 6.0mg/L and 7.3mg/L at a depth of 4.75m.

The Managing Director of the consultancy firm said, ” the results look fantastic!”

Hydro Innovations will generally pair Venturi-Aerators up with Gorman-Rupp self-priming pumps to allow installation of the systems on the banks of dams and lagoons, making them safer and more cost-effective to maintain. When the right pumps are selected, oxygen transfer rates can be as high as 1.86kg O2/kWh, making good use of available power.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-205x205.jpg)