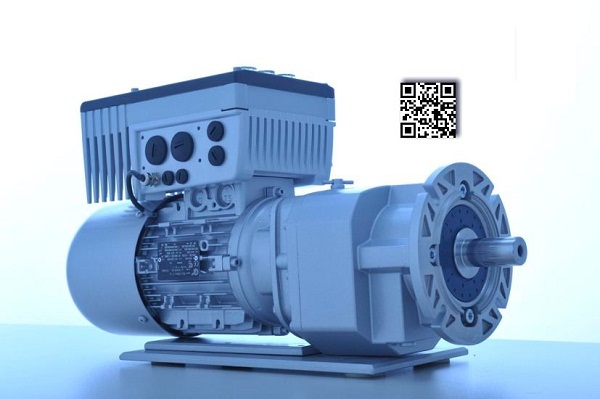

NORD DRIVESYSTEMS has more confidence in the abilities of these decentralised drives and this supplier of complete drive systems equips its SK 200E inverters, which are available for installation near the motor or as motor-integrated models, with the same wide functional range as the centralised SK 500E series of cabinet-installed inverters.

The decentralised frequency inverters not only provide an ample overload capacity of 200 per cent, but also enable users to position the drive with high precision. The relative positions (incremental or endless axes) or absolute values (rotary tables / fixed, repeatable positions) can be controlled with binary values through the SK 200E's inputs and stored within the drive.

Alternatively, they can be set via a fieldbus system. Positions can be detected via incremental encoders (an onboard referencing function is included in the inverters' basic equipment), or position values provided by a CANopen absolute encoder may be directly imported. Configuration is easy, fast, and concise – only a few parameters need to be set for commissioning and optimisation.

Moreover, the encoder signals can be used for speed control, which enables an unprecedented dynamic performance from asynchronous motors. This approach has proven a viable alternative to servo drives, e.g. in palletisers (see video linked via QR code). For such and similar scenarios, NORD provides individually assembled decentralised drive solutions from a single source.