Level measurement has seen considerable change over the past decades – from purely mechanical level measurement through to complex electronic sensors using various measuring principles. The large number of different technologies for measuring level (such as hydrostatic, reed chain, magnetoresistivity, radar, ultrasound, optical and many more) today offers the user the possibility to choose the most suitable sensor technology for his individual application.

In continuous level measurement, hydrostatic pressure (also known as hydrostatic level measurement) is the principal sensor technology and measuring principle, with a market share of approximately 40 per cent 1 by sales volume.

Still considerably ahead of ultrasound and radar technologies, hydro- static sensors for level measurement are installed in more than every second measuring point. Thus, the immense importance of this technology is reflected in its steady growth from US$ 650 M in the pre-crisis year of 2008, to around US$ 770 M in 20131.

What is meant by hydrostatics?

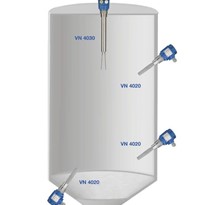

Hydrostatic pressure sensors are used for the measurement of level or filling height of a liquid. Hydro- static pressure measurement is suited for level measurement due to the hydrostatic effect of non- flowing fluids. This physical principle describes the effect of the weight force of a stationary, meaning non-flowing, liquid on a measuring point. This weight force is usually described as "hydrostatic pressure."

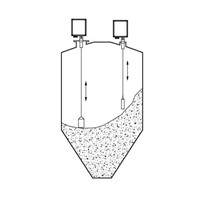

The most important condition for hydrostatic level measurement is what is called the "hydrostatic paradox." This means that, regardless of the shape and volume of a vessel, the hydrostatic pressure at the measuring point of a tank or vessel is proportional only to the filling height (Fig. 1). Thus, despite the apparent contradiction of an over-proportional increase or decrease in the volume or weight of a liquid with change in height, the hydrostatic pressure at the measuring point is solely proportional to the absolute filling height, and not to the filling quantity.

A static liquid generates, through its specific density and the acting force of gravity, a corresponding weight force or hydrostatic pressure which increases proportionally with the filling height. Consequently, the hydrostatic pressure represents a direct measure of the fill level or degree of filling of a tank or vessel.

Since, the hydrostatic pressure is not dependent upon the volume or the shape of a vessel, it can be used directly for the measurement of the fill level, but must be further processed to “measure” the fill quantity. From the measured level, using a ‚tank linearisation table‘, the actual fill quantity present in the vessel can be calculated.

A tank linearisation table documents, for different pressure values, the respective fill quantity present in the vessel. From the values documented, a curve can then be derived which presents the user a corresponding fill volume for every hydrostatic pressure measured. This calculation is usually carried out in the PLC, so that the operator has a display of the actual fill quantity present in the vessel, directly on-screen.

Continue reading "Fundamentals of hydrostatic level measurement."