A medium sized forklift weighs about the same as an average dump truck — and can cause just as much damage or injury. In fact, forklifts are still one of the greatest health and safety hazards in our warehouses and manufacturing sites.

According to the Occupational Safety and Health Administration (OSHA) in the USA, the equipment operator is the victim in 42 percent of fatal forklift incidents. This means that nearly 60 percent of incident casualties are suffered by innocent pedestrians or fellow workers.

These statistics are similar worldwide, and thousands more are injured every year from either falling loads or manoeuvring forklifts on site. But it’s not just the forklift operator who has a responsibility for safety.

Smart site design and safety features a good starting point for WAREHOUSE safety

As with any risk, preventing a serious injury starts with design. An intelligent warehouse floor design considers movement and activity flows throughout the warehouse and identifies high-risk, forklift-only areas to eliminate interactions between workers and forklifts.

Outside of forklift-only areas, the use of barriers and designated walkways will isolate workers from machinery. Forklift safety features should also be considered. Does the forklift have: an audible alarm, overhead guards, blue tracking lights, an operator presence system, automatic stability systems, or orange forks to increase visibility?

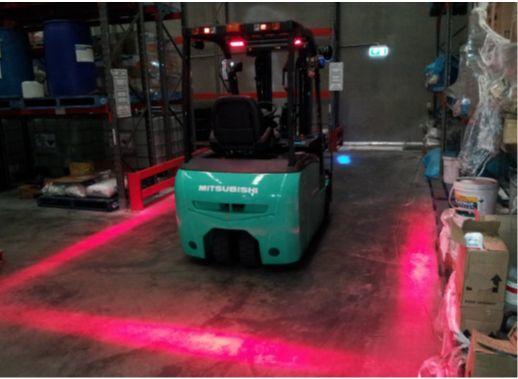

Forklift ‘Safety Halo’ an innovative method for working around machinery

No matter how much we improve our site designs for workplace safety, there will always be some interaction between forklifts operators and non-operators. So what can pedestrians, workers and operators do to minimize risk in the workplace?

At MLA Holdings Pty Ltd, we have implemented the forklift ‘Safety Halo’ to help our customers and staff safely navigate working around forklifts. The initiative is based around two safety halos, one set 1 meter from the machine and another 2 meters from the machine. The “Safety Halo” is a virtual two-ring safety zone around any forklift or mobile equipment and, as a worker or pedestrian approaches the forklift, a set of simple rules apply within each safety halo zone:

- The Danger Zone (1 m): the operator must immobilise the forklift to prevent any injury

- The Warning Zone (2m): requires equal focus by both the operator and pedestrian. Both must make eye contact; the pedestrian must indicate their intentions; and the operator is required to yield the right of way.

This new forklift policy also states that the forklift operator must always look in the direction of travel. If view is obstructed, the forklift must be operated in reverse. The ‘Safety Halo’ is a simple way to facilitate the need for increased awareness regarding safe factory-floor equipment transport practice. And it’s easy to implement

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)