Sure, a little ramp wear and tear over time is perfectly normal.

But using ramps incorrectly will accelerate the process. And there’s a point where misuse can become risky and unreliable.

At Ramp Champ, we’ve seen some horror stories: ramps overloaded, bouncing around in the back of a ute or left out in the weather through winter.

So, let’s run through the signs of ramp wear and tear and the correct maintenance, so you can safely move from A to B.

Maintenance varies depending on your ramp type (a poodle prancing up a ramp is different to an excavator). This guide will show you how to care for:

- Construction loading ramps

- Yard ramps

- ATV and motorcycle ramps

- Dog ramps

- Rubber threshold and kerb ramps

So scroll through, find your ramp and learn how to keep it in ship shape.

Construction Loading Ramps: Common Signs Of Wear And Tear

Construction loading ramps are one of the most important ramps to give a regular look over. Because a 6 tonne bit of kit is not something you want to mess around with.

With construction ramps, if you’re using the correct weight, height and machinery type, wear and tear should be minimal.

But if it’s been regularly misused or stored incorrectly, you might find rungs bending, beam damage, hairline cracks or welds breaking...

In other words, a bad day in the office.

How To Maintain Construction Loading Ramps

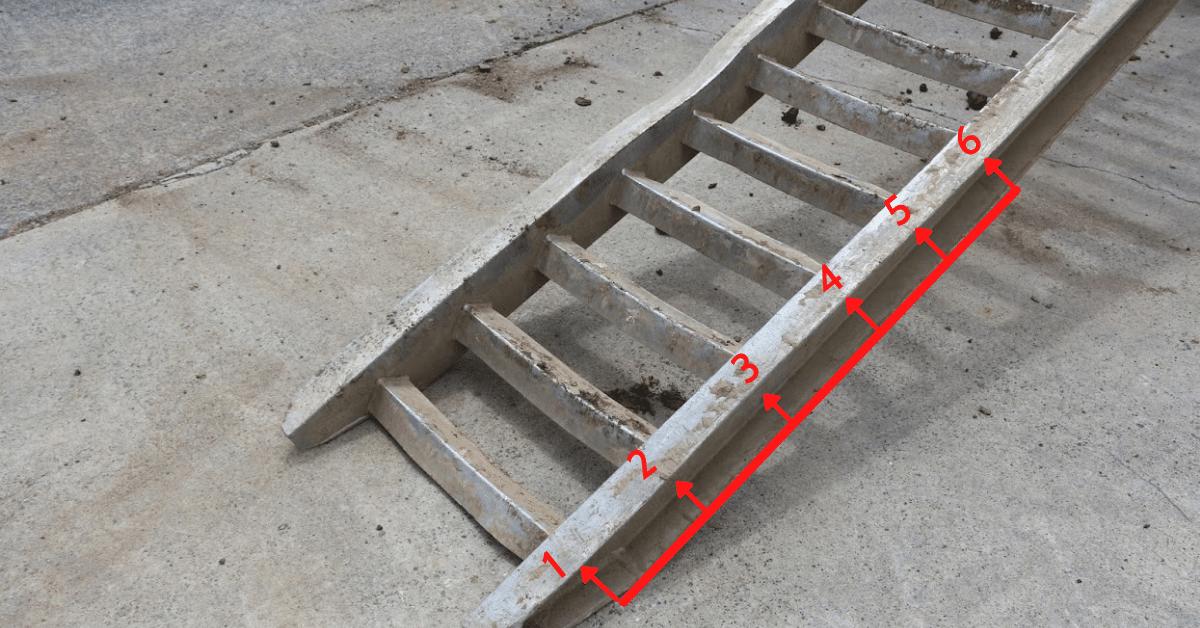

- Regularly check the first 6 rungs of your ramp, as they take the majority of the weight from the machine in the loading process.

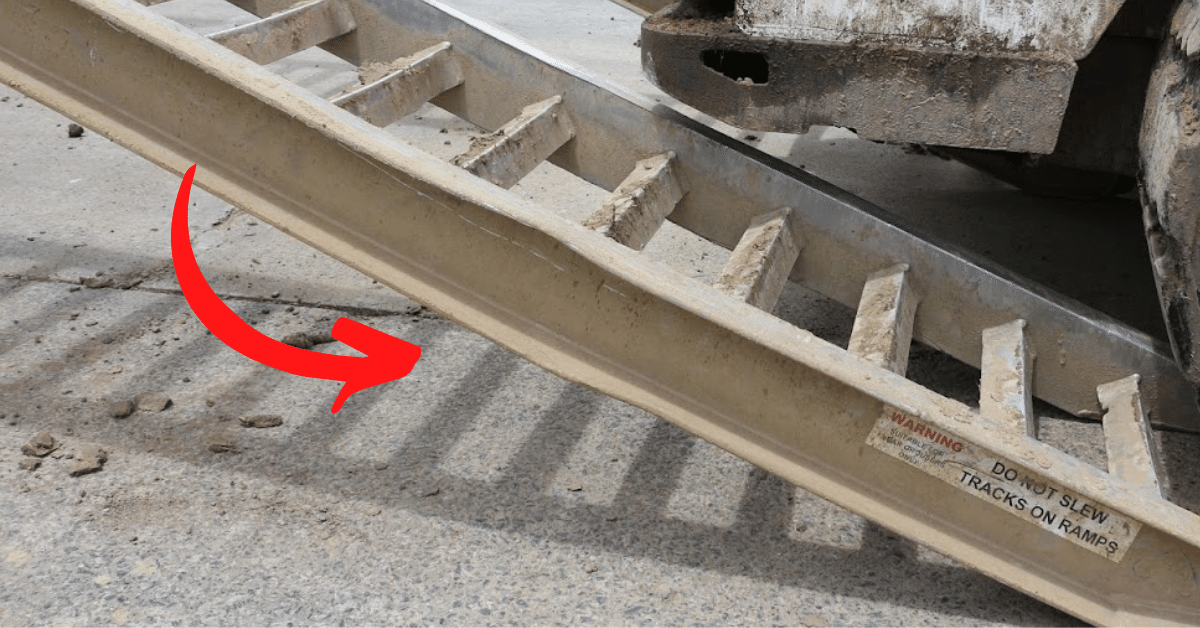

- Check the beams of your loading ramps, as these can become bent over time. This is particularly common with skid steer loaders that bottom out and knock the beams on the way down.

- When you’re checking your beams, also look for hairline stress cracks. These may look tiny (but it won’t be long before they open up).

- Check the weldings, as these may weaken if the ramp is corroding or supporting too much excess weight.

- Ensure your ramps support the weight of your machine (check the rating against the weight of your machine - including attachments and machine liquids).

- Avoid letting mates borrow your loading ramps, especially if they operate a heavier machine than what your ramps are capable of!

- Make sure the ramp rung type is suited to your machine. Steel track machines need ramps with rungs that are specially designed for steel tracks. Whereas rubber track machines need ramps designed for rubber tracks and rubber tyres.

- Securely store the ramp while in transit (avoid it flying around loose in the back of your truck).

- When not in use, store your loading ramp out of the weather.

- Clean your ramp if it becomes wet or muddy, as this could lead to corrosion.

Finally, avoid buying second hand ramps, as you never know whether these have been properly maintained or misused in the past.

We recommend checking your loading ramps at least every 6 months (more often if you use them daily). This includes washing it down and thoroughly checking the beams, rungs and welds

Yard Ramps: Common Signs Of Wear And Tear

Forklift and yard ramps are often made to be incredibly durable with an impressive carrying capacity. But over time, exposure to weather and lack of maintenance can lead to rust, wearing and even the breakdown of the hydraulic pumps.

How To Maintain Yard Ramps

- When not in use, store your yard ramp under shelter or out of the weather to avoid deterioration.

- Clean your ramp if it becomes wet or dirty, as this could lead to corrosion.

- Assess and replace areas of high traffic, such as the ramp surface.

- For mobile yard ramps, regularly check the tyre pressures.

- For yard ramps with hydraulic pumps, check the joins and hinge points before each use.

- Replace the hydraulic oil every 12 months to ensure it operates efficiently.

ATV And Motorcycle Ramps: Common Signs Of Wear And Tear

For ATV and motorcycle ramps, common signs of wear and tear include dents, cracks and corroded joins, most often caused by improper use (like exceeding the capacity) or improper storage (like leaving it outside in the weather).

How To Maintain Motorcycle Ramps

- When not in use, store your ATV or motorcycle ramp under shelter or out of the weather to avoid deterioration.

- Clean your ramp after it becomes wet or muddy, as this could lead to corrosion.

- Check the hinge points to ensure there are no corrosion or cracks.

- Secure the ramp in transit (we’re looking at you, the ones who toss it into the back of the ute).

- Make sure the motorcycle or ATV tyres are narrower than the ramp.

- Driving your motorcycle or ATV up the ramp is often the preferred way, but avoid doing this if it means you’ll exceed the ramp weight capacity.

As a general rule, we recommend checking your ATV and motorcycle ramp once a year (but more often if you regularly head out for a spin).

Dog Ramps: Common Signs Of Wear And Tear

Just like our lil’ best mates, dog ramps come in all different shapes and sizes.

And wear and tear, such as bending or cracking, is often caused by overloading the ramp (in other words, using a Chihuahua-sized ramp for your Great Dane). Leaving the ramp out in the weather can also damage the material, lift the grip tape or lead to corrosion.

How To Maintain Dog Ramps

- Keep your dog ramps indoors or out of the weather. This is especially relevant for wooden ramps, as wet weather can cause the timber to rot.

- Make sure the ramp is correctly suited to your dog so they don’t bend, crack or split the ramp.

- Check the hinge points to ensure there are no corrosion or cracks.

- If you’ve got a muddy dog on your hands, hose down the ramp afterwards as mud can erode the surface material.

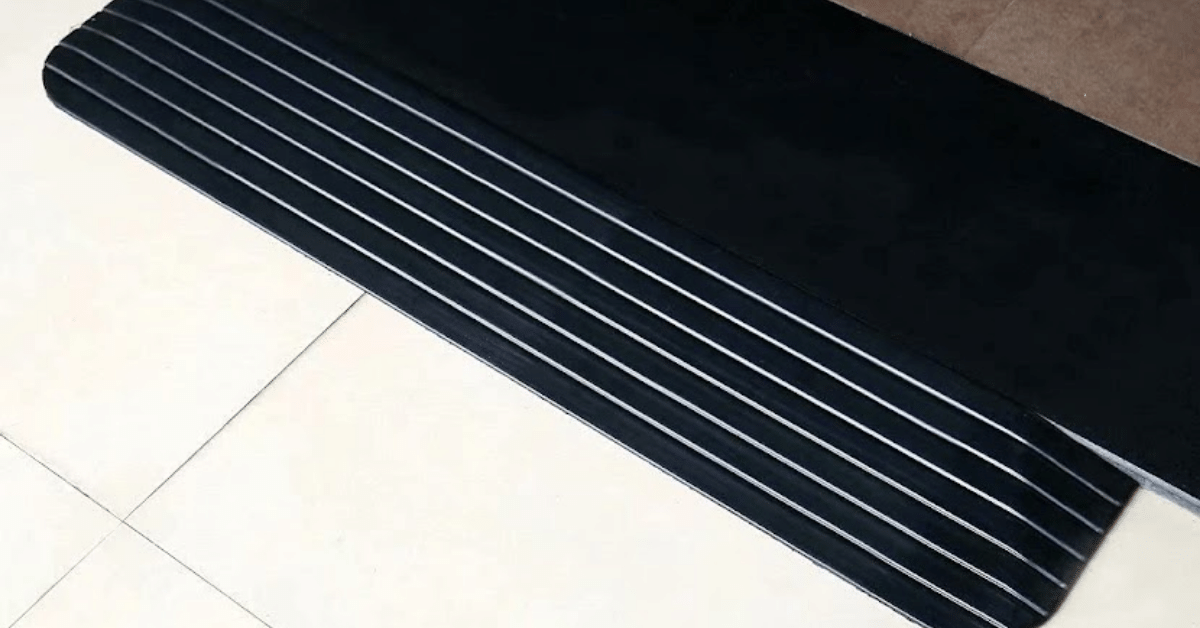

Rubber Threshold And Kerb Ramps: Common Signs Of Wear And Tear

Whether you’re using a rubber ramp for your doorway or kerb, the signs of wear and tear are similar. Excessive use can lead to splits, chips or eroded edges - which usually happens on the thinnest section of the wedge.

How To Maintain Rubber Threshold And Kerb Ramps

- ??Clean your ramp regularly with mild detergent and warm water. Avoid using a pressure washer, strong cleaning chemicals or rough brushes directly on the ramp as this could lead to wear and tear.

- If you’re concerned about your threshold ramp moving, secure the ramp using an adhesive sealant. We recommend Sikaflex which is available at Bunnings.

- If you’d like to keep your rubber kerb ramp secure, many options come with permanent fixing holes.

Keep Your Ramp Going In Years To Come

Now you know how to properly care for your ramp, you can avoid excessive wear and tear, and keep it spick and span in years to come.

At Ramp Champ, we’re Australia’s largest and best ramp retailer. We sell thousands of ramps every year and ship to any location in Australia (and we mean any - just try us).

We’ve also seen our fair share of customers with damaged ramps due to misuse. So if you read through this guide and you’re wondering whether your ramp is too far gone, check out our Warning Signs Your Ramp Needs Replacing.