What is box build assembly?

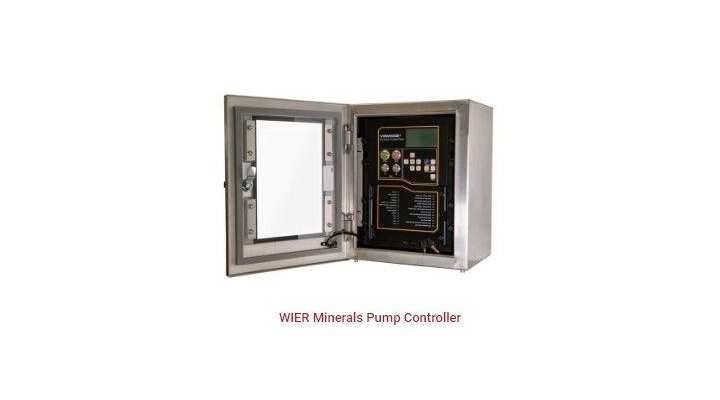

Box build assembly is a general term given to all assembly processes in electronics design and manufacture chains other than producing printed circuit boards. Sometimes referred to as systems integration, box build assembly can include anything from placing a circuit board into an enclosure to creating a complex electronic, fully-integrated system.

Why is it beneficial to use the same box build and printed circuit board manufacturing company?

By using the same company to both create your circuit board and complete your box build needs, you are eliminating any room for error as you are trusting one company to complete a full system assembly. Communication between two companies may be limited, causing them to complete the box build services incorrectly or damage the circuit board in their manufacturing process.

Utilising one company to complete both services is a much more cost-efficient option as you eliminate the need to transport your products between two manufacturers. This ensures the final product can be created much more quickly and efficiently.

How can box build assembly create a more reliable product?

Often, turnkey products are much more reliable as a prototype of the product can be created by one manufacturer that is subject to tests before mass production and the product being shipped to the end-user. If flaws in the product are found, the manufacturing company can analyse both the printed circuit board and box build processes to find and eliminate the issue. By outsourcing your design and manufacturing needs to one company, you can have total confidence in the end-result of your product, as the product can be tested more accurately and efficiently.

Hetech electronics design and manufacturing

If you would like to outsource both your printed circuit board and box build assembly needs, trust Hetech. We are your electronics design and manufacturing partner and provide complete turnkey services, so you can rely on us to support you from concept to creation.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)