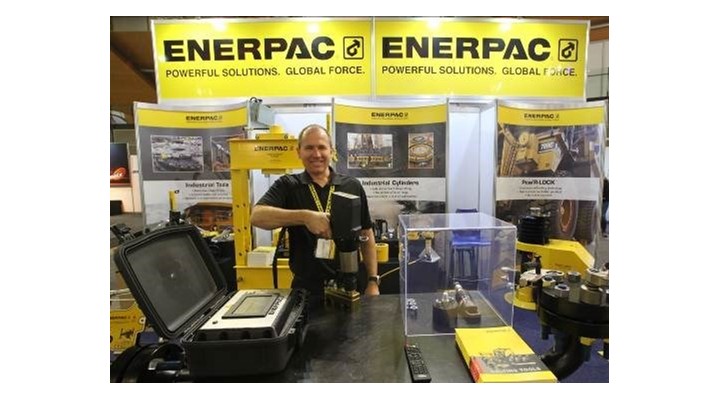

The latest non-impact professional bolting tools, powerful lifting technologies and portable hydraulics were all on show at the Enerpac stand.

A highlight of the display was Enerpac's new Electric Torque Wrench (ETW), which improves bolting efficiency and performance for industries requiring high repetition and high precision such as mining and energy, infrastructure, oil and gas, power generation, rail, petrochemical and processing plants.

"Not only is the ETW a more efficient tool, it also records torque measurements as you're working. Fastening records can be viewed on-screen and transferred through a standard USB connection, saving the laborious task of manually recording each measurement," says Andrew Marsh, National Bolting Manager, Enerpac Australia.

"There was a very strong interest in the ETW from the mining industry, where the simplicity and reliability of the tool were important considerations. Users can input a nominal torque value followed by a specific angle of rotation, allowing for functionality, efficiency and ease-of-use," said Marsh.

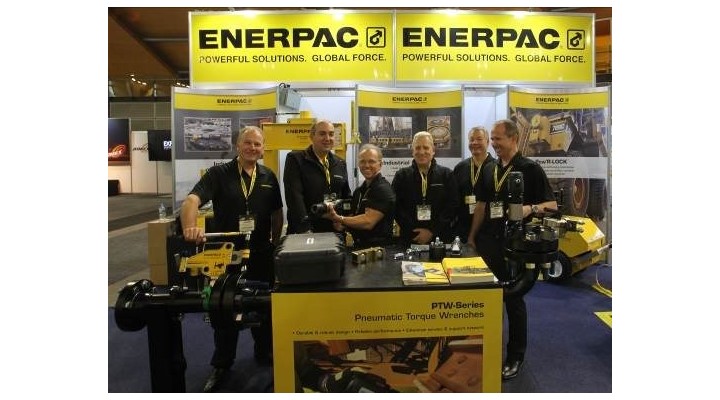

Safety was another strong focus at this year's AIMEX, and Enerpac staff were on hand to demonstrate the safety features of their industry-leading hydraulic tools.

Enerpac Asia-Pacific Marketing Manager and Goal Zero safety team member Antony Cooper said that he received positive feedback on Enerpac's new Goal Zero On-Site Safety Training programme.

"I had a number of people in the mining industry talk to me about our new on-site safety training. The overwhelming response was that it was great to see an industry leader not just selling products, but also providing their expertise," he said.

Enerpac's Goal Zero safety programmes draw on the organisation's practical workplace experience in more than 30 countries and its commitment to promote the goal of zero harm to employees, customers and end users of Enerpac and other-brand heavy lift, shift, position, fabrication and bolting machinery used across Australia, New Zealand and PNG.

Western Australian Territory Manager David Capper is working in partnership with his East Coast colleague and SE Queensland/ Northern NSW Territory Manager Sandy Whyman, along with Enerpac's network of Territory Managers, to bring the safety message on-site to audiences who might not otherwise have the time or opportunity to bring themselves up to date with technology advances and the latest safety and maintenance best practice global standards.

"We've found that companies are often too busy to send their workers offsite for training, so we've created a programme where we come to them. These are practical, down-to-earth safety training development courses designed to deliver immediate benefits from course leaders who combine local expertise with global knowledge and standards. The key outcomes on which they focus are reduced accidents and downtime," said Cooper.

Technologies on display at AIMEX 2017 included:

Enerpac's new ETW – in maximum torque capacities from 1625-8135Nm (1200-6000 ft-lbs) – incorporates the latest advanced SMART safety and efficiency technology based on Enerpac's 50 years of experience as an industry leader in bolting solutions and is fully backed by Enerpac's extensive service and distribution network throughout Australasia and New Zealand to facilitate optimum reliability and safety compliance.

The ETW complements Enerpac's comprehensive range of hydraulic torque wrenches and bolting tools, which is highly valuable to companies seeking time-saving choice, consistency of quality and traceability of outcomes.

Advances incorporated into the design of the Electric Torque Wrench include a large seven-inch touchscreen on the control box as well as a bright 3-line LED display on the back of the tool, so that it can be read easily, even in bright sunlight.

Enerpac's PL-Series Pow'R-LOCK Portable Lifting system with full-time locking capability is designed and purpose-built to provide safe and secure lifting for heavy off-highway machinery including Haul trucks and large industrial equipment.

Pow'R-LOCK accomplishes its load-holding protection by utilising a control system that maintains the position of a rotating locking collar, providing a mechanical lock regardless of cylinder movement and control cycle.

The heavy-duty lifting system integrates into a rugged mobile cart with a high capacity and compact 700 bar (10,000 psi) hydraulic cylinder and an air-driven hydraulic pump unit with complete valving and control systems. There are two versions which feature strokes of 356 and 622mm (14" and 24.5"), that are ideal for companies where time and safety are paramount, such as mining and heavy transport.

XC-Series Cordless Hydraulic Pumps

Enerpac's XC Series cordless pumps, which now come in single and double acting versions, offer the performance capabilities of an electric pump with the convenient portability of a hand pump.

Both types of Enerpac XC-Series cordless pumps actuate hydraulic tools as fast as a basic electric powered pump and create up to 700 bar (10,000 psi) of pressure. The option of double-acting power – offering powered extension and retraction of an array of widely used cylinders and tools – extends further the versatility of XC-Series Gen II cordless pumps, which weigh less than most common hand pumps and are capable of being used in any position.

Non-impact Professional Bolting Equipment

Enerpac's comprehensive range of mechanical and hydraulic bolting equipment provides precise & effective force to make your work more productive, safer, and easier to perform. The tools are designed to streamline many of Australasian industry's most common, time-consuming and potentially hazardous maintenance and fabrication tasks.

The Enerpac family of non-impact bolting tools includes hydraulic torque wrenches and torque wrench pumps, nut splitters, flange spreaders and alignment tools engineered to complete the most difficult bolting jobs with the degree of safety and accuracy demanded in today's work environment.

High performance hydraulic bolt tensioners, above, that facilitate faster, safer and more precise maintenance and fabrication operations. The GT-Series universal bolt tensioners – in capacities up to 2845kN (320 ton) at 1500 bar – are particularly suitable where operators want to achieve known and accurate bolt loads across multiple applications, such as pipelines and flanges.

Hydraulic Cylinders and Pumps

Enerpac will also showcase at AIMEX hydraulic and mechanical technology that is lighter, quieter, safer, more powerful and more efficient in use, including its comprehensive range of cylinders and pumps.

Ultima two-speed hand pumps feature an innovative design that provides greater ease-of-use with handle effort reduced by up to 20 percent without compromising speed or performance. The two speed operation of the ULTIMA series of steel hand pumps means the faster first stage can be used to quickly position the plunger of the hydraulic cylinder where it is needed, before employing the powerful second stage (700-2800 bar, 10,000-40,000 PSI) to do the heavy work.

RC Duo hydraulic cylinders from Enerpac optimise extension capabilities while minimising retraction times to get jobs done faster and with outstanding reliability and safety. The compact and powerful high pressure 700 bar RC Duo cylinders – in capacities from 5-95 tons and long-stroke models typically from 156-362mm – are part of Enerpac's RC general purpose cylinder family, which is one of the world's most widely used compact, powerful and ruggedly versatile high-pressure cylinder ranges.

New generation hydraulic pumps, including the TQ-700E Classic 700 bar electric pump, above, which features a brushless motor designed for continuous usage and simplified maintenance in high cycle applications and demanding environments. The pump – which weighs less than 30kg dry and operates well from generators – is also ideal for mobile plant workshops on mine and resource sites, and field maintenance for dragline, shovel and heavy plant repair.