Dry fog technology applies to crushing, screening, conveying, loading, and unloading of dry bulk materials.

"When done properly, dry fog dust control systems are as effective as dust extraction with bag houses and much less expensive to implement, operate, and maintain"

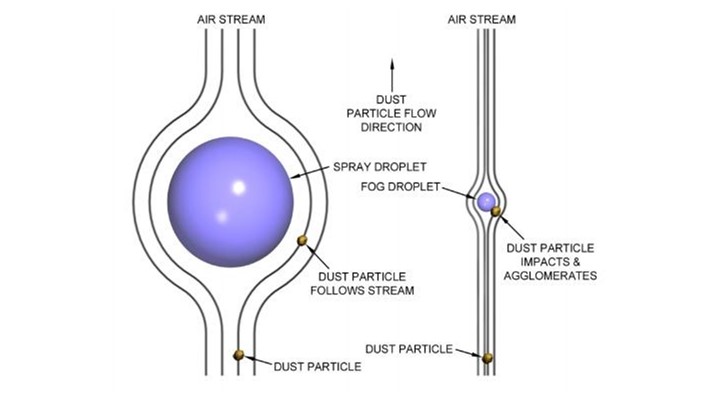

Dry Fog dust control systems use special acoustic nozzles to fracture water into a cloud of extremely small droplets that are in the same size range as the airborne respirable dust. Acting in the same way that clouds cleanse the atmosphere of dust, the water droplets agglomerate with (attach to) the dust particles, become heavier, and settle back to their source. The graphic nearby illustrates the principal. If the water and dust particles are very much different in size, the slipstream created by the larger one carries the smaller one around it and impact is prevented. When they are about the same size, the slip stream effect is too small to prevent collision.

Successful application of dry fog technology to industrial dust control requires four design elements:

- Containment,

- An adequate quantity of fog

- Retention time

- Collection surface.

Of the four, containment is the most important.

Transfer enclosures need to be a little larger than the norm, truck and rail dumps require features to contain the displaced air by rolling it back into the hopper, and bins need protection from wind and other outside influences.

Calculating the quantity of fog required begins with an estimation of the quantity of dust that is airborne, applying a scrubbing ratio (water mass flow divided by dust mass flow), and making adjustments for other factors such as retention time and collection surface within the containment. We use US EPA data and experience to estimate the dust and we use scrubbing ratios ranging from 3 to 10 depending on the application. For a typical dry mineral ore transfer point, the water flow rate will range from 0.1 to 0.3 gpm /1000 st/hr (.04 to 1.1 lpm / 1000 mt/hr).

Acoustic Nozzles are key to the reliable delivery of fog into the system. The FP series acoustic nozzle which was developed by Sonic Development Corporation, these devices use compressed air to create high frequency sound waves that shatter water into the fog sized droplets needed while retaining adequate kinetic energy to project the fog where it’s needed and penetrate through opposing air flows.

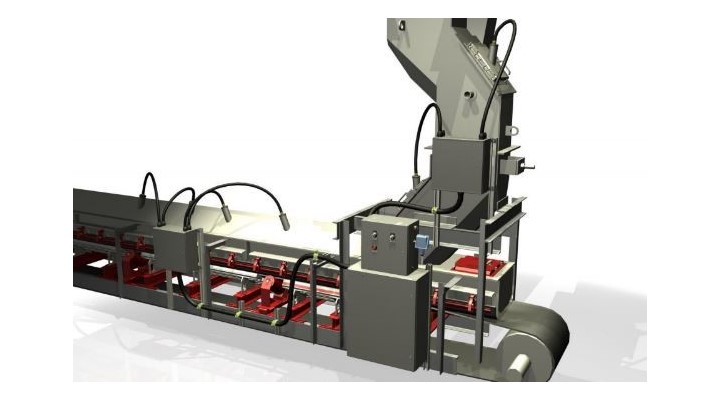

The nozzles incorporate relatively large liquid ports which act along with the acoustic nature of the nozzles to resist plugging. Nozzles are available in three sizes with air capacities ranging from 1 to 8 cfm (1.7 to 13.6 nm3/hr). A typical transfer point will require between 6 and 20 nozzles depending on belt size and speed, flow rate, chute height, material nature, and other factors. Operating pressures are well within normal industrial plant norms. A typical transfer point dry fog system will look something like the nearby model. There are nozzles in the head box insuring that there is fog surrounding the flow of material through the chute, in the tail box unless the chute is of a “dustless” design, and in the loading zone downstream of the chute. The loading zone is divided into individual scrubbing chambers separated with internal rubber baffles that distribute air flow and act as collecting surface for the agglomerated dust.

If the conveyor support, skirt rubber, and liners are properly designed, there will be zero visible emissions and control efficiency will be as good as, or better than, dust extraction, Dry fog is applied to crushers and screens in the same manner as at transfers. The only difference is that the discharge of a crusher or the fines chute under the screen will carry more airborne dust than a transfer point requiring

more fog.

Truck and rail dumps are a bit more difficult and each one presents its own challenge. Containment becomes more difficult and expensive and compromises must be made between dust control and production considerations. A deep, single sided, enclosed truck dump hopper with internal belt baffles is the ideal solution. The enclosure is called a “stilling shed” because of its function to contain and “still” the displaced air created from dumping the huge haul trucks. A picture nearby is a stilling shed at a major sub-bituminous coal mine in the Powder River Basin in Wyoming, USA. The picture below it shows the density and energy of the fog “filter” we create over an open hopper in a copper mine in Chile that captures and settles dust carried by the displaced and induced air flow. Less fog is required on closed dumps than on open ones.

Virtually all of the mines in both regions use dry fog for some or all of their dust control applications and even those that choose to apply dust extraction with fabric filters have a need for dry fog at the point where the dust is returned from the collector to the conveyor.

There are many ways to control dust in dry bulk material handling applications and all have their place. Dry fog is particularly well suited to most containable dust sources, it’s sometimes the only choice that has a chance of success, and it sometimes cannot be used.In most plants, a well thought out combination of technologies will provide the best solution.

If you would like to discuss any dust control requirements please contact us for more information or a free quote.