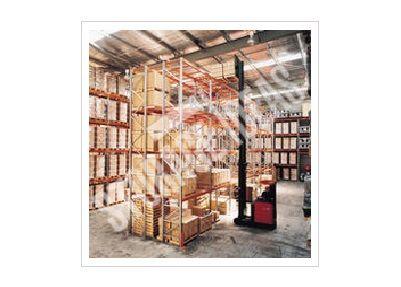

An existing storage building was upgraded and Colby racking was installed where previously pallets of drums were block stacked on top of each other, up to four high. Storage Requirements: Four standard drums per pallet were to be stored on racks up to five pallets high and four oversized drums per pallet on racks two and three pallets high. A total of 1700 pallet positions were required.

1. Designing for the Seismic Code

| CUSTOMER: |

Aust. Nuclear Science & Tech. Organisation |

|---|---|

| LOCATION: |

Lucas Heights, Sydney, New South Wales |

| BACKGROUND: |

The facility is on the site of Australia's nuclear research reactor in Sydney's southern suburbs. An existing storage building was upgraded and Colby racking was installed where previously pallets of drums were block stacked on top of each other, up to four high. |

| STORAGE REQUIREMENTS: |

Four standard drums per pallet were to be stored on racks up to five pallets high and four oversized drums per pallet on racks two and three pallets high. A total of 1700 pallet positions were required. |

| SPECIAL REQUIREMENTS: |

Erected in stages, the entire system was specially engineered and strengthened to meet seismic code design requirements. |

2. Our Storage Solution

Storage Ideas was chosen because it had the products to meet the requirements of the design, at the right price. It was also able to complete the project in stages within the desired timeframe.

To satisfy the Seismic Code Requirements, Colby heavy-duty Selective and Double-Deep Racking with additional bracing was installed. Particular emphasis was placed on extra fixing of racking at the floor connection to ensure the structure's overall strength and stability.

An independent engineer certified the design.

3. Customer Benefits

The installation of racking has increased the storage capacity of the facility and created a safer working environment for the operators.

Double-Deep Racking

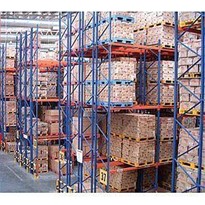

Although not a truly selective system, Double-Deep Racking offers many companies a cost-effective method of bulk storage. Access and stock rotation is compromised compared to Selective Pallet Racking, however, cube utilisation is much higher.

Specially designed forklifts use a variety of double-deep reach mechanisms to allow easy placement and retrieval of pallets.

Key features of Double-Deep Racking include:

- Access to a minimum of 50% of pallets

- Relatively low cost racking system

- 40% increase in storage capacity