Key Takeaways

- Productivity boost: Implementing a cobot welder can increase welding throughput by 50% to 150%, allowing you to get more done with your existing team.

- Cost vs. ROI: Expect an initial investment of $40,000 to $100,000+ for a full system. With consistent use, many businesses see a Return on Investment (ROI) within 6-18 months due to reduced labour costs and increased output.

- Ease of use is paramount: Prioritise systems with intuitive, tablet-based programming. Many cobots can be programmed by a non-expert for simple tasks in under 15 minutes.

- Safety and compliance: In Australia, your system must undergo a risk assessment based on AS/NZS 4024 (Safety of machinery) and ISO 15066 (Collaborative robots) standards. This is a non-negotiable legal requirement.

- It's an investment in skill: Cobot welders don't replace skilled welders; they take over the repetitive tasks, freeing your team for more complex, high-value work.

- Your process dictates success. A cobot welder requires consistent parts and a repeatable workflow; it automates a good process but cannot fix a broken one, so assess your readiness first.

- Fixturing is not an accessory. Budget 10-25% of your total system cost for high-quality jigs and clamps, as how you hold the part is just as critical as the robot welding it.

Introduction: The future of Australian fabrication is collaborative

For Australian manufacturers, the twin challenges of skilled labour shortages and the need for higher productivity have never been more acute. The solution for many isn't replacing people, but empowering them with smarter automation. Cobot welders, collaborative robots designed to work safely alongside humans, are bringing the benefits of automation to small and medium-sized workshops that previously found it out of reach. This guide will walk you through the essential information you need to make an informed decision about integrating a cobot welder into your operations.

What applications are best for a cobot welder?

Cobot welders are most effective for repetitive, short to medium-length welds where consistency is key. They are a perfect fit for production runs of similar components.

- MIG/MAG Welding: This is the sweet spot for cobot welders, ideal for a wide range of materials like mild steel, stainless steel, and aluminium.

- TIG Welding: While more complex, advanced cobot systems are increasingly capable of performing high-quality TIG welds, which is valuable for industries requiring a high-end cosmetic finish.

Understanding the investment and your return

A cobot welder is a strategic investment that pays dividends through increased efficiency.

Price points and financing

A complete, ready-to-weld system in Australia typically ranges from $40,000 to $100,000+. The price is influenced by the cobot's size, the quality of the welding power source, and any additional peripherals like workpiece positioners.

To preserve your cash flow, consider financing options. A chattel mortgage is a popular choice for Australian businesses, as you own the asset from day one and can claim the full GST on the purchase price in your next BAS.

Calculating the return

The ROI comes from a dramatic boost in operational efficiency.

- Increased Throughput: A cobot can maintain 85-95% arc-on time compared to a human welder's 60-70%, significantly increasing the number of parts welded per shift.

- Consistent Quality: Cobots deliver precise, repeatable welds, drastically reducing costly rework, grinding, and material waste.

Maintenance, warranty, and support

Cobot systems are designed for industrial use and require straightforward maintenance.

- Routine Maintenance: Daily or weekly tasks, such as replacing welding gun consumables (nozzles, tips) and cleaning spatter, are typically performed by your existing welders.

- Annual Servicing: Budget for a professional service call once a year to calibrate the arm and service the power source, costing around $1,000 - $3,000.

- Warranty and Support: Expect a standard warranty of 1 to 3 years on the cobot arm. Crucially, ensure your supplier has a strong, Australia-based technical support team and local availability of spare parts to minimise potential downtime.

Australian compliance and safety

Safety is paramount when humans and robots share a workspace. In Australia, your cobot welding cell must comply with key standards.

- Key Standards: Your system must be risk-assessed against AS/NZS 4024.1:2019 (Safety of machinery) and the principles of ISO 15066:2016 (Collaborative robots).

- Risk Assessment: A comprehensive risk assessment of the entire welding cell is a legal requirement under WHS law. This will determine the necessary safety measures, which may include light curtains or safety scanners, even if a full cage is not needed.

- Fume Extraction: Standard Australian WHS requirements for welding fume control must be strictly followed.

Actionable Tip: Insist that your supplier provides a comprehensive risk assessment as part of their proposal to ensure compliance from day one.

Assessing your parts and processes for automation readiness

Before you even request a quote for a cobot welder, you must conduct an honest assessment of your own operations. A cobot is a precision tool that thrives on consistency; it automates and perfects a good process, but it cannot fix a chaotic one. This is the "garbage in, garbage out" principle of automation.

To determine if you have the right work for a cobot, run through this simple readiness checklist:

- Repeatability: Do you manufacture parts in consistent batches? Cobots deliver the best ROI on repetitive tasks. If you are welding batches of 20, 50, or 100+ of the same item, you have a prime candidate for automation.

- Consistency: Are the parts that arrive for welding consistent? A cobot follows a precise path. If your parts have wide dimensional tolerances or poor fit-up from the cutting and bending stage, the cobot will struggle to produce a good weld.

- Simplicity: Are the required welds relatively straightforward and easy to access? Cobots excel at simple, repetitive seams (straight lines, circles, stitch welds). They are less suited for highly complex, out-of-position welds that require constant human judgment.

Finally, analyse your process flow. A cobot that can weld a part in two minutes is useless if it takes an operator ten minutes to prepare and deliver the next part. Map the flow of materials to and from the proposed cobot cell. A cobot that is constantly waiting for work is not a productive asset; you must ensure your upstream processes can keep it fed.

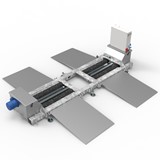

A guide to fixturing and part presentation

How you hold the part is as important as the robot that welds it. In welding automation, your fixturing (the jigs and clamps that hold the workpiece) is not an optional extra; it is a core and critical component of the entire system. Its job is to present the part to the cobot in the exact same position and orientation, every single time. Inconsistent fixturing is the number one cause of failed cobot welding projects.

Types of fixturing

- Manual Clamps: Simple, cost-effective toggle clamps are excellent for lower volume or less frequent jobs. They are flexible but slower to use.

- Pneumatic Clamps: For higher volume production, pneumatic clamps are faster and provide more consistent clamping pressure, reducing variability.

- Modular Fixturing Tables: These offer the ultimate in flexibility. A modular table with a grid of holes allows you to use a "Lego-like" system of clamps, blocks, and vices that can be quickly reconfigured for different jobs, making them ideal for high-mix, low-volume workshops.

Budgeting for your fixturing

A common and costly mistake is to spend the entire budget on the robot and neglect the fixturing. As a rule of thumb, you should allocate between 10% and 25% of your total system cost for high-quality, repeatable fixturing. This investment is essential to guarantee the precision and reliability that the cobot is capable of delivering.

Common questions from buyers

1. Do I need a robotics expert to program it?

No. Modern cobots are designed for ease of use, with intuitive tablet interfaces. A skilled welder can typically learn to program simple, repetitive tasks in under an hour.

2. Is it truly safe to use without a cage?

Yes, with a proper risk assessment. Cobots have built-in safety features that limit their force and speed, allowing them to stop if they make contact with a person. However, your risk assessment will determine if additional safety measures like light curtains are needed to protect against the welding arc or hot components.

3. Will a cobot replace my skilled welders?

No, it augments them. The cobot handles the dull and repetitive tasks, freeing your skilled team for more complex, high-value work like custom fabrication, intricate TIG welds, and programming the cobot itself. This increases job satisfaction and makes your entire operation more efficient.

Conclusion: A strategic step forward

The cobot welder represents a pivotal shift for Australian manufacturing, offering a flexible and cost-effective solution to boost productivity and improve quality. By understanding the technology, calculating the strong potential for ROI, and prioritising Australian compliance standards, you can make an informed decision. This isn't just about buying a robot; it's about investing in the future capability of your workforce and positioning your business to thrive.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)