Accurately measuring temperature during the process can be the difference between success and failure in a run. If the temperature is incorrect, it can cause faulty or damaged products. Pyrometers are a type of temperature measuring device which are now being used in many industries due to the fact they can measure temperature without having to be in direct contact with the item they are measuring.

What is the history of pyrometers?

The first pyrometer was the human eye, blacksmiths used their eyes to determine the colour of the metal to estimate the temperature of the metal they were working with. Scientists in the late 1700’s developed more advanced pyrometers that could measure temperature more accurately. Also, a pyrometer called the thermoscope was invented which used the expansion of liquid to measure temperature.

In the 1800 and 1900’s there where big developments in pyrometry, which created more sophisticated and accurate pyrometers. This development was optical pyrometry the use of spectral emissions and colour to measure temperature.

1917 was the first practical infrared pyrometer was designed, it used a prism to separate the infrared radiation emitted from an object. Later in the mid-20th century electronics and computer technology were introduced to pyrometers which lead to the advancement of the modern-day pyrometer.

What is a modern Pyrometer?

A modern pyrometer is designed to detect an object emitting thermal radiation which advises the temperature of the object. With advanced optics and electronics, the pyrometer captures the radiation reading and determines the objects temperature with a degree of accuracy.

A modern pyrometer is designed to detect an object emitting thermal radiation which advises the temperature of the object. With advanced optics and electronics, the pyrometer captures the radiation reading and determines the objects temperature with a degree of accuracy.

There are a few types of pyrometers, ones such as optical pyrometers, radiation pyrometers and infrared pyrometers. Optical measures the colour of thermal radiation emitted by the object. Radiation measures the total amount of thermal radiation emitted and Infrared use advanced optics to focus on a spot on the object and measures the thermal radiation emitted by the spot.

What is an Infrared Pyrometer?

An infrared pyrometer commonly known as IR pyrometer, the basic principle behind infrared pyrometers is the fact that all objects above absolute zero emit infrared radiation in the form of heat. With advanced optic to focus on a specific spot on an object and measures the thermal radiation (in the form of electromagnetic waves) emitted by that spot. IR pyrometer then converts radiation into an electrical signal which then analyses and gives an accurate temperature reading, infrared pyrometers can read temperatures from -50°C to 3000°C, depending on the IR model and the industrial application.

What are the Advantages of Infrared Pyrometers?

The main advantage of an infrared pyrometer is that they are non-contact and non-intrusive in obtaining temperature reading, this is ideal when the object being measure is of very high temperature or moving too quickly making it impossible to having contact with the object.

The IR pyrometers are fast and accurate reducing the time required to take a measurement and eliminating the need for calibration, the IR pyrometers are very accurate, with some models capable of measuring to within 0.1°C.

Where do we use the Infrared Pyrometers?

There is a wide range of industries that use IR pyrometers, such as the glass manufacturing, steel and metal production, food and beverage processing and scientific research.

There is a wide range of industries that use IR pyrometers, such as the glass manufacturing, steel and metal production, food and beverage processing and scientific research.

The glass industry use IR pyrometers for measuring the temperature of the glass as it is being formed and to monitor the cooling down process of the glass. The IR pyrometer in metal/steel industries is used to measure the temperature of the molten metal in the furnaces and other high-temperature environments. In the food and beverage industry the pyrometer measures the temperature of the cooking process to ensure the product is safe for consumption.

What to consider when setting up a pyrometer system?

Setting up a pyrometer system in your industrial process there are a few crucial factors to consider, we have set up a few pointers on how to select what you require for your system.

Factor 1. You need to know what temperature range you need to measure, the distance between the pyrometer and the targeted object and any other specific requirements for your industrial measurement application.

Factor 2. Once you have determined your measurement requirements you need to select the correct pyrometer. There are many options with different configurations each one suited to different industrial applications. It is better to use a specialist like us Pyrosales to assist you in your selection with our expertise who can assist you in the correct selection.

Factor 3. The installation of the pyrometer system will require a specialist to ensure the pyrometer or pyrometers are mounted correctly and securely so there is no chance of vibration. Aligned with the targeted objects is crucial to have accurate temperature measurement.

Factor 4. The plant control system needs to be installed or connected to the pyrometer or pyrometers so monitoring can commence. You will need to configure your control system to receive the pyrometers signal and use it to control your temperature process.

Pyrosales works very closely with our distributor of pyrometers Accurate Sensor Technologies (AST). An example of an AST system being used.

Pyrometers for a Lab Grown Diamond.

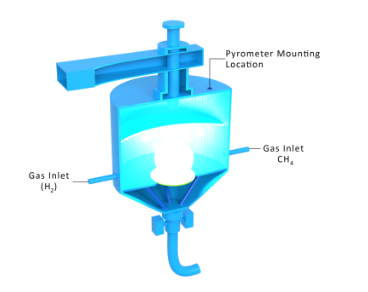

Plasma Chemical Vapour Deposition (PCVD) is a technique by which lab growing diamonds can be grown from a hydrocarbon gas mixture. In the CVD process, a thin slice of diamond seed (often an HPHT produced diamond) is placed in a sealed chamber at high temperature and high pressure. The chamber is then filled with a carbon rich gas (usually methane) along with other gases. Then, the gases are ionised into plasma using microwaves, lasers, or other techniques. The Ionisation breaks the molecular bonds in the gases and the pure carbon adheres to the diamond seed and slowly builds up into up into a crystal, atom by atom and layer by layer form.

Plasma Chemical Vapour Deposition (PCVD) is a technique by which lab growing diamonds can be grown from a hydrocarbon gas mixture. In the CVD process, a thin slice of diamond seed (often an HPHT produced diamond) is placed in a sealed chamber at high temperature and high pressure. The chamber is then filled with a carbon rich gas (usually methane) along with other gases. Then, the gases are ionised into plasma using microwaves, lasers, or other techniques. The Ionisation breaks the molecular bonds in the gases and the pure carbon adheres to the diamond seed and slowly builds up into up into a crystal, atom by atom and layer by layer form.

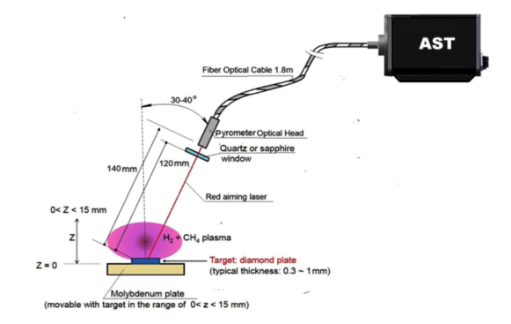

The method for producing diamonds includes positioning a diamond in a holder such that a thermal contact is made with a side surface of the diamond adjacent to an edge of a growth surface of the diamond, measuring temperature of the growth surface of the diamond to generate temperature measurements, controlling temperature of the growth surface based upon the temperature measurements and growing single crystal diamond by microwave plasma chemical vapour deposition on the growth surface, wherein the growth rate of the diamond is greater than 1μm per hour. In this entire process temperature plays a critical role. We need to measure the temperature of the target diamond rather than the plasma.

Temperature Measurement by Infrared Pyrometers.

A non-contact temperature measurement device is positioned to measure the temperature of the diamond across the grown surface of the diamond. The pyrometer is mounted on a glass window of a chamber to read the temperature of target diamond. The challenging part of the application is Plasma emits IR energy at specific wavelengths and we need to measure consistent temperature of the target through the plasma. AST offers non-contact type IR based Pyrometer which works in selected wavelength where plasma is transparent.

Key Features

Key Features

- Temperature Range – 350°C to 1800°C

- Fast response time in millisecond

- Laser sighting

- Connectivity via USB 2.0, Bluetooth V2.0 and RS-232 or RS-485 Serial interface

- Measure the temperature of target through plasma at specific wavelength.

In conclusion a pyrometer system is a vital component in many industrial processes, providing curtail temperature measurement data that creates and maintains a safe and efficient operations. Each pyrometer system comes with different configurations, each suited for specific industrial applications. The design of a pyrometer system is better set up with knowledge of a specialist like us Pyrosales.

Please contact us for more information or a site visit to consult on your temperature requirement.