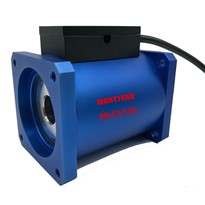

Torque sensors are professional instruments used to measure and record the force and torque on a rotating system.

While normally small and compact, torque sensors are powerful and critical in their applications. Generally, torque sensors use a strain gauge applied to a rotating shaft or axel to measure the force and torque. Strain gauges are small and sensitive assemblies that can fit perfectly into a torque sensor.

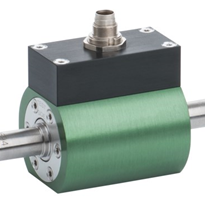

There are two main types of torque sensors: static and dynamic. Static torque is easier to measure compared to dynamic torque. Dynamic torque sensors have short response times and high torsional stiffness. Measuring range needs to be strictly monitored to avoid overload for both static and dynamic torque sensors.

Torque and force can be measured both clockwise and counter-clockwise. Both dynamic and static torque sensors are suitable to measure static working torque. However, dynamic working torque can only be measured by dynamic torque sensors.

The working principles between static and dynamic torque sensors are quite different. Static torque sensors convert strain generated by force into an electric signal, which has a linear relationship with it. Dynamic torque sensors can measure the electrical signal of the torsion from the elastic shaft; then a strain bridge is formed on the elastic shaft via strain electrical measuring technology, to provide power to the strain bridge. After amplifying the signal, it will be transformed into a frequency signal proportional to the response.

Dynamic torque sensors are widely used in many industries, such as waste-water treatment, manufacturing, and processing operations. Machinery and equipment, cars, aircraft and ships also rely on torque sensor to support their operation. Static torque sensors are generally used in testing machines, static torque detection and other test systems.

Torque sensors plays an important role in so many applications. Choosing the most suitable torque sensor is vital for owners and operators seeking to save costs.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)