Cost control is among the initiatives of medium-sized businesses to achieve consistent revenue goals. One area where it’s critical is in securing products for shipment While fully automatic strapping machines may seem like the gold standard, semi-automatic strapping machines often strike the perfect balance between performance and cost for medium-sized businesses.

One of the common traps among business owners is being lured by the idea of buying new or fully automated equipment long before they can afford to have one. The dread of the purchase always comes when sudden instances require funding in the business or the ROI didn’t go as expected.

Scaling and maintaining the business are the stages of the business that requires careful decisions. Every decision can make or break the business. That's why every purchase of equipment must be studied carefully.

In this article, gain some insights on which equipment fits your type of business and what will be more cost-efficient for your goals.

Understanding the Basics: Semi-Automatic vs. Automatic Strapping Machines

The primary difference between semi-automatic and automatic strapping machines lies in their level of automation and suitability for different business needs. In general, these three factors hold crucial data that will help you develop a more educated decision when purchasing equipment.

#1 Automation and Operation

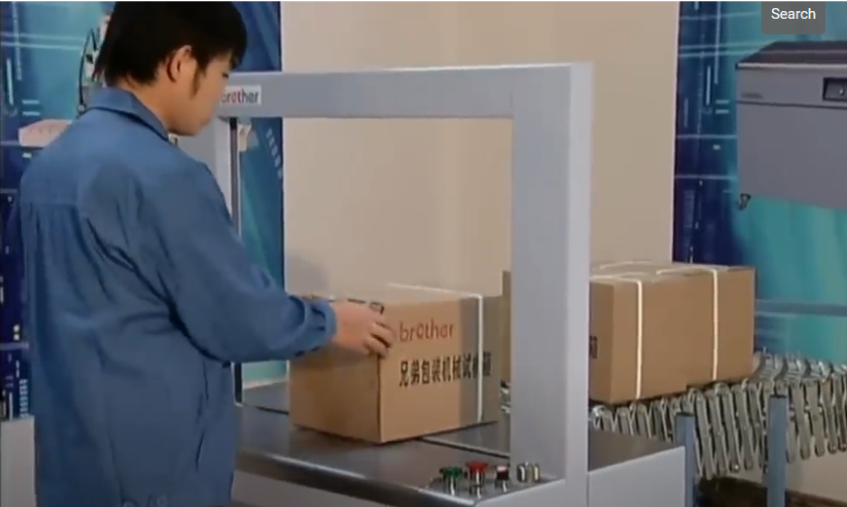

Alt-text: Automatic strapping machine used for strapping small boxes

The most telling difference will always be on the distinct features of each equipment. One machine is ideal for high-speed production while the other one is the best for versatile or flexible use.

Automatic strapping machines are fully automated that can perform the entire strapping process—from applying the strap to tightening and sealing it. Only two manual steps are required from the operator which include placing the package on the equipment and stepping on the pedal to strap and seal it.

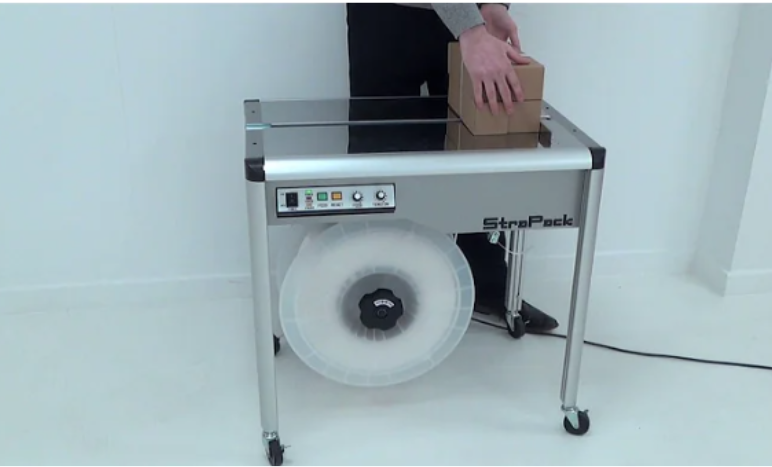

For semi-automatic strapping machines, operators need to manually position the strap around the package and feed it into the machine, which then tightens and seals the strap. It would take approximately three steps per strap for the operator to successfully strap one package. The steps usually include:

- Place the package on the equipment.

- Feed the strap around the package.

- Press the equipment so it will tighten and seal the straps

#2 Volume and Production Speed

Alt-text: Operator wrapping a strap around a box in a semi-automatic strapping machine

The speed of automatic strapping machines makes them ideal for businesses with a high-volume of packages to strap daily where speed and consistency are crucial.

Semi-automatic strapping machines, on the other hand, combine automation and manual input which makes it ideal for businesses with low to medium production volumes and varying packaging sizes and shapes.

Semi automatic strapping machines can produce around 10-15 packages per hour while automatic doubles it with 30-60 packages per hour. With that, there’s around 50% difference between the two machines. However, factors such as operator speed should also be considered for more accurate analysis.

#3 Cost and Investment

Due to their advanced features automatic strapping machines typically require a higher initial investment. However, the increased efficiency and reduced labour costs can lead to significant long-term savings, particularly in high-volume operations.

The investment costs depend on the technology used by the equipment. Here’s a price range per model range:

- Entry-Level or Basic Models: These are suitable for businesses that need a basic level of automation which can range from AUD 5,000 to AUD 10,000.

- Mid-Range Models: These machines offer more features, better build quality, and are suitable for medium to high-volume operations, ranging from AUD 10,000 to AUD 25,000.

- High-End Models: For advanced, fully automated machines that can handle high volumes and offer integration with existing production lines, prices can range from AUD 25,000 to AUD 50,000 or more.

Semi-automatic machines sit between automation and versatility offered by manual input and are more affordable. Due to those two factors, they are considered as a more viable option for medium-sized businesses or those with budget constraints.

While semi-automatic machines may result in higher ongoing labour costs due to manual operation, their lower upfront cost and versatility still offers a certain level of automation with less financial risk.

Why Semi-Automatic Strapping Machines Are Ideal for Medium-Sized Businesses

Medium-sized businesses, regardless of their size, are not exempted to potential risks. Therefore, balancing cost, efficiency, and flexibility is a trifecta that they often consider in managing or controlling operation costs.

Within that trifecta, semi-automatic strapping machines are among the possible options due to the following factors:

- Flexibility and Versatility: Semi-automatic strapping machines offer a room for flexible adjustments that allows businesses to strap packages of varying sizes and shapes. This particularly benefits companies with a diverse range of products.

- Cost-Effectiveness: Semi-automatic strapping machines present a more affordable alternative for those who are not yet ready to invest in a fully automated system but still need to optimise their packaging efficiency. A step before businesses fully automate. This makes them accessible to businesses.

- Operation: The training required to operate a semi-automatic machine is also less extensive compared to manual strapping. Less skilled workers will have a smaller learning curve since the automation will do all the tightening and sealing of the straps, requiring less need for specialised staff.

- Scalability: Semi-automatic strapping machines help businesses in their growth phase to prepare to scale without too much financial risk to meet evolving demands.

- Return on Investment (ROI): While the initial cost of a semi-automatic strapping machine is lower, businesses must consider the total cost of ownership (TCO) over the equipment’s useful life.

Semi-automatic machines generally offer a favourable ROI for medium-sized businesses, as they provide a balance between upfront investment and operational efficiency without relying on cash injections and protect their cash flow. Total Cost of Ownership (TCO) includes - Maintenance

- Repairs

- Operating costs

- Potential downtime.

- Adaptability to Business Needs: The full benefit of semi-automatic strapping machines shine in times of fluctuating volumes often experienced by medium-sized businesses. There would be less frustration for its wasted capability and the pressure to gain an ROI in times of volume changes in the production.

Find The Perfect Strapping Equipment for Your Business with IndustrySearch

Gain more insights if semi-automatic strapping machines suit your business needs with IndustrySearch. Sourcing industrial equipment is made easy with one platform where you can connect with the best semi-automatic strapping machine providers in Australia.

Take the first step towards optimising your operations—get your personalised quote today and start scaling your business.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)