FMS (Force Measuring Systems) web guides detect the position of the material with web guide sensors, calculate the deviation from the reference position, and then maintain the material at the required position with a steering frame actuator.

FMS’s wide range of web tension control and web guiding products offer many possible modular combinations to cover virtually all applications.

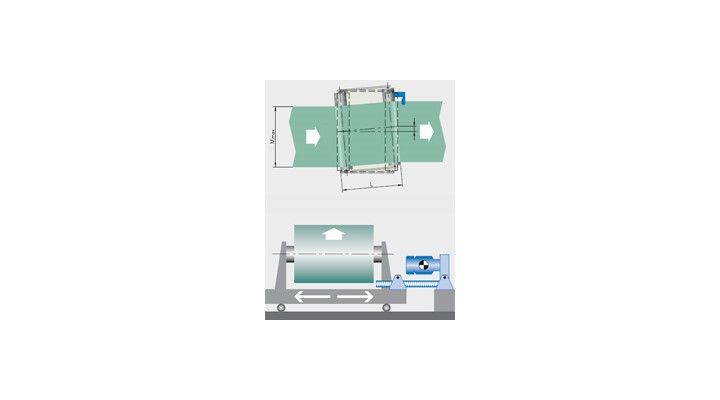

Closed loop control, see figure 1

- The web guide sensor detects the position of the material web.

- The web guide controller calculates the deviation from the reference position and drives the steering frame actuator accordingly.

- The steering frame actuator maintains the position of the material web at the reference location, thereby laterally controlling the web material.

FMS-webMASTER , see figure 2

The FMS web guide is mounted as close as possible to the location where the positional accuracy is required. With an FMS-webMASTER, the length of the steering frame (L) should be the same as the maximum material width (Mmax). For optimal control, the web guide sensor is mounted as close as possible to the outfeed of the steering frame. With an FMS-webDIRECTOR the guiding of the material will take place over a virtual turning point in the infeed run of the steering frame.

FMS-winderGLIDE, see figure 3

FMS-winderGLIDE The actuators of the FMS-winderGLIDE series have been specifically developed for use in unwind and winding stations. Utilizing powerful drives ensures they are suitable for moving large rolls and stands. The web guide sensor is mounted as close as possible to the nearest idler roller. The electric drives of the FMS actuators offer superior operation when compared to hydraulic drives when processing foodstuff and pharmaceutical packaging because there is no risk of contamination with e.g. oils or other hydraulic liquids.

For more information about Web Guiding and Web Control Systems please call or email for more information