Skyzer is a 19 year old Australian company that specialises in product lifecycle solutions, focusing mainly on electrical devices. They help their customers save money and deliver at any scale by providing flexible product assembly, firmware loading, repair, refurbishment, and logistics services; as well as End Of Life secure destruction and recycling solutions.

Skyzer have built their reputation on highly customised assembly lines, with the utmost data and IP security. Raise 3D Printers have provided Skyzer the tools to offer their clients customised fixtures, jigs and assemblies; electrical housings for small run productions; replacement parts for clients’ products for refurbishing and repairs; and highly customised assembly lines

Prior to the incorporation of 3D Printing Skyzer could simply not offer some of the services that they offer today before 3D Printing. They used to rely on toolmakers or injection moulding houses to get tooling made up or CNC up parts, which was massively prohibitive. "It could cost upwards of USD $10,000 for moulds, so was only viable on very large scale projects" explains Troy Sneddon, CEO Skyzer.

How did you come to choose the Raise 3D Printer?

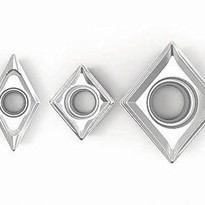

A close up look at a customised production line.

Recently Skyzer have customised an assembly line for a client that is allowing the impossible to be possible, and seeing the manufacture of a client’s product on a large scale for commercial distribution in Australia. The product is required to be assembled at a steep angle, with circular geometries at different heights. This was otherwise extremely difficult and time-consuming without the tailor made mechanical assembly jig that Skyzer designed for their client and print on the Raise3D printers in-house. Both decreasing clients costs, protecting their IP and confidentialities, and allowing rapid production and as such a much shorter cheaper path to market for their client. The customised assembly jig removes mechanical stresses on the product during assembly, preventing weakening of the product or damage to sub-components. In addition, it eliminates the risk of the product’s external enclosure being scratched during assembly and test.

Perhaps most significantly, the 3D Printed assembly jig significantly reduced assembly labour times while also improving production quality through the guided alignment of components. The Raise 3D Printed jigs provided an overall production cost saving of 32%.

How did you come to 3D Printing?

"We have always prided ourselves on being early adopters of technology that can help our clients. We initially invested in 3D Printing technologies in 2012 with a Makerbot Replicator 2. Today we run a fleet of Raise 3D Pro 3 printers in both our Sydney and Melbourne facilities." Troy Sneddon - Skyzer CEO

The Raise 3D ecosystem offers Skyzer a more professional solution for mass production; coupled with cloud management for seamless supervision and sharing between their sites. "In addition, the power behind the Ideamaker software and the machines themselves has taken us a huge step forward from the Makerbot machines we started with." Mr Sneddon explains.

Skyzer made the decision to invest in their first Raise3D Printer to increase production capabilities. Now they own a fleet of Raises' allowing them to get product design timelines down for their clients (in one case from 3 months down to 2 weeks) through 3D printed fit checks and design iterations.

“The reliability of the machines means we can print with confidence throughout the night and the Pro 3 edition snap in extruders are a real improvement on previous models and will definitely decrease maintenance-based downtimes”. Skyzer managers also heavily rely on the highresolution camera on the Pro 3 models to supervise printing remotely, and across multiple sites.

How has 3D Printing improved product development at Skyzer?

Mr Sneddon explains that 3D Printing has allowed significant labour cost reduction on many projects; while also allowing for the development of assembly jigs that prevent damage to products during assembly by supporting irregular geometries.

"Naturally we have seen labour cost and parts wastage savings" explains Mr Sneddon "however there are also the substantial cost savings in comparison to alternative tooling and mould costs". Generally, Skyzer have found that 3D Printing provides them a higher value offering to clients, driving further company growth.

In addition, Mr Sneddon believes that 3D Printing has "inspired even higher levels of creativity throughout our whole team. Even our Finance team have asked for 3D printing of their solutions to office-based problems! "

What challenges did you face in adapting 3D Printers?

The terrible reliability of early products made it difficult to even learn the craft; and it is a new set of skills, a new method of production with its own idiosyncrasies that must be learned. Our lack of experience in diagnosing hardware problems with the printers was a real problem in the beginning and is actually what lead us to Bilby 3D's door initially. Since then, their ongoing support has been vital for our adoption and expansion of this technology within our company.

What developments does Skyzer look forward to in 3D Printing?

Metal 3D printing and larger printers, coupled with more exotic materials have a huge potential to impact what Skyzer can do for their clients. "We foresee exciting opportunities evolving within in-house product design and development, further contributing to the expansion of our client solutions on offer".

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)