As a seasoned professional in the field of conveyors, you understand the importance of selecting the right accessories to optimize the performance and efficiency of your conveyor system. These accessories play a vital role in ensuring smooth material handling and maximizing productivity. In this article, we will explore key conveyor system accessories that you are already familiar with and discuss their significance in enhancing the overall functionality of the system.

1. Rollers: Supporting Material Flow

Rollers are an integral part of any conveyor system, providing support and facilitating the smooth movement of materials along the conveyor path. With your expertise, you know that selecting the right type of rollers, considering factors such as load capacity, material composition, and durability, is crucial. Properly maintained rollers reduce friction and prevent material damage, contributing to efficient material flow and extending the lifespan of the conveyor system.

2. Belts: Efficient Material Transfer

Conveyor belts are essential accessories that enable the seamless transfer of materials from one point to another. As an expert, you understand the importance of choosing the appropriate belt type, considering factors such as the nature of the materials, load capacity, and speed requirements. You know that well-maintained belts, with proper tension and tracking, ensure reliable and efficient material transfer, minimizing downtime and product damage.

3. Pulleys and Drums: Powering the System

Pulleys and drums are key components that work in tandem with conveyor belts to drive the system. Your expertise allows you to carefully select pulleys and drums based on factors such as load capacity, rotational speed, and system layout. You understand the significance of proper alignment and regular maintenance to ensure optimal power transmission and prevent belt slippage or damage.

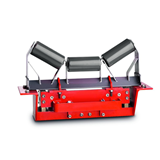

4. Idlers and Tensioners: Maintaining Belt Performance

As a seasoned professional, you recognize the importance of idlers and tensioners in maintaining proper belt tension and tracking. You understand how strategically positioned idlers support the belt, ensuring it remains aligned and reducing the risk of misalignment or sagging. Tensioners, on the other hand, play a crucial role in adjusting belt tension to maintain optimal performance. Your expertise in selecting and positioning idlers and tensioners contributes to the smooth operation and longevity of the conveyor system.

5. Conveyor Skirting and Sealing Systems: Containment and Compliance

In your vast knowledge of conveyor systems, you are aware of the importance of conveyor skirting and sealing systems. These accessories ensure effective material containment and prevent environmental contamination. Your expertise in selecting appropriate skirting materials and sealing systems helps contain material spillage, minimize dust and debris, and comply with safety and environmental regulations. By incorporating these accessories, you contribute to a cleaner and safer working environment.

6. Impact Beds and Load Zones: Protecting the System

As a seasoned professional, you understand the significance of impact beds and load zones in protecting the conveyor system from excessive wear and tear. With your expertise, you carefully select and position impact beds to absorb the impact of falling materials, preventing damage to the belt and structure. Load zones equipped with skirting and impact bars offer controlled loading, reducing material spillage and enhancing overall system performance. Your knowledge ensures the longevity of the conveyor system and minimizes maintenance costs.

7. Conveyor Diverters and Merge Units: Efficient Material Flow Control

Your expertise in conveyor systems includes the understanding of conveyor diverters and merge units, which provide efficient control over material flow. By strategically implementing diverters and merge units, you optimize material routing and prevent bottlenecks or congestion. Your knowledge of the system's requirements allows you to select the right diverters and merge units, ensuring smooth and uninterrupted material flow, ultimately increasing productivity.

Upgrading Your Conveyor System: Enhancing Efficiency with Sensors and Advanced Options

As a seasoned professional in the field of conveyors, you understand the importance of continuous improvement and staying up-to-date with the latest advancements in the industry. Upgrading your conveyor system not only enhances its efficiency but also improves overall productivity and safety. In this article, we will explore the benefits of upgrading your conveyor system with sensors and other advanced options, and how they can revolutionize your material handling operations.

1. Sensor Technology: Enhancing Control and Automation

Sensors play a vital role in modern conveyor systems, providing real-time data and enabling precise control and automation. By integrating sensors into your conveyor system, you gain valuable insights into various parameters such as speed, position, temperature, and product detection. This data allows for intelligent control and automation, optimizing material flow, reducing errors, and improving overall system efficiency. Sensors such as proximity sensors, photoelectric sensors, and temperature sensors can be strategically placed along the conveyor to provide accurate and timely information.

2. Vision Systems: Ensuring Product Quality and Accuracy

Vision systems have become increasingly popular in conveyor system upgrades, particularly in industries with high-quality standards. These systems use cameras and advanced imaging technology to inspect products, detect defects, and ensure accuracy in sorting and packaging processes. By integrating vision systems into your conveyor system, you can automate quality control, reduce the risk of faulty products reaching customers, and enhance customer satisfaction. Vision systems can identify color variations, dimensional discrepancies, and other defects, allowing for immediate corrective actions.

3. Barcode and RFID Technology: Streamlining Tracking and Traceability

Barcode and RFID (Radio Frequency Identification) technology are powerful tools for tracking and traceability in conveyor systems. Upgrading your system with barcode scanners or RFID readers enables seamless identification and tracking of products as they move along the conveyor. This technology eliminates manual data entry, reduces errors, and streamlines inventory management. By integrating barcode and RFID technology, you can improve order accuracy, enhance supply chain visibility, and meet stringent compliance requirements.

4. Automated Sorting Systems: Increasing Throughput and Accuracy

If your material handling operations involve sorting products based on specific criteria, upgrading to an automated sorting system can significantly enhance efficiency and accuracy. Automated sorting systems utilize advanced algorithms, sensors, and diverter mechanisms to divert products into the appropriate chutes or destinations. By integrating automated sorting systems into your conveyor system, you can increase throughput, minimize manual handling, and reduce the risk of errors. These systems are particularly valuable in high-volume distribution centers, e-commerce fulfillment, and postal services.

5. Conveyor Belt Cleaning Systems: Improving Maintenance and Hygiene

Maintaining a clean and hygienic conveyor system is essential, especially in industries such as food processing, pharmaceuticals, and healthcare. Upgrading your conveyor system with automated belt cleaning systems helps remove debris, contaminants, and product residue from the belts, ensuring product integrity and preventing cross-contamination. These cleaning systems, including brush cleaners, scrapers, and air knives, can be integrated into the conveyor system to improve hygiene, reduce manual cleaning efforts, and extend the lifespan of the belts.

6. Energy-Efficient Motors and Drives: Optimizing Power Consumption

Energy efficiency is a growing concern in modern conveyor systems. Upgrading to energy-efficient motors and drives can help optimize power consumption and reduce operating costs. Advanced motor technologies, such as servo motors and variable frequency drives (VFDs), allow for precise control of speed and acceleration, matching the system's power requirements to the workload. By upgrading to energy-efficient motors and drives, you can reduce energy waste, lower carbon footprint, and achieve significant cost savings in the long run.

7. Conveyor System Integration: Seamless Interoperability

To further enhance the capabilities of your upgraded conveyor system, seamless integration with other equipment and systems is crucial. Upgrading your system to enable interoperability with other technologies, such as warehouse management systems (WMS) or programmable logic controllers (PLC), allows for efficient communication and synchronization of operations. By integrating your conveyor system with other systems, you can achieve better coordination, optimize material flow, and streamline overall processes.

8. Remote Monitoring and Control: Real-Time Insights and Maintenance

In today's digital age, remote monitoring and control have become indispensable tools for optimizing conveyor system performance. Upgrading your system to enable remote access and monitoring provides real-time insights into system operations, performance metrics, and maintenance needs. With remote access capabilities, you can monitor critical parameters, receive alerts for potential issues, and make informed decisions to prevent downtime or optimize system efficiency. Remote control functionalities also allow for convenient adjustments, troubleshooting, and software updates without the need for on-site presence.

In conclusion, selecting the right accessories and considering advanced options for upgrading conveyor systems is crucial for optimizing performance, enhancing efficiency, and improving overall productivity and safety. Accessories such as rollers, belts, pulleys, and skirting systems play a vital role in supporting material flow, ensuring efficient material transfer, and maintaining belt performance. Upgrading with advanced options like sensor technology, vision systems, barcode and RFID technology, automated sorting systems, and energy-efficient motors and drives brings automation, accurate tracking, enhanced sorting capabilities, cleanliness, energy savings, and seamless integration to the conveyor system. Additionally, incorporating remote monitoring and control enables real-time insights and maintenance, leading to proactive decision-making and reduced downtime. By leveraging these accessories and upgrades, businesses can achieve higher productivity, better operational control, and improved customer satisfaction, making their conveyor systems more efficient and reliable.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.jpg)