The foamy products we are talking about include liquids such as milk, body wash, detergents and other chemical foamy liquids.

A bottom up filling system minimises the risk of foam and frothing that can happen when liquids are dropped into a container from a height. Using the bottom up filling method, the nozzle of the bottom up filling system drops through the spout of a container and down to the bottom of the container before proceeding to fill the container with shampoo, body wash, detergent, cleaning products or other foamy liquids.

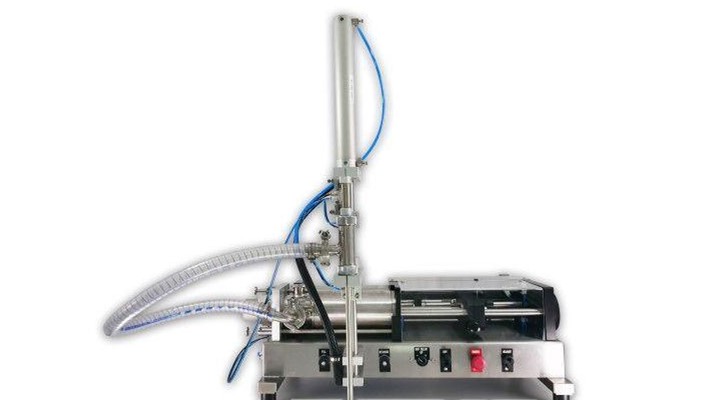

The overall process makes for an easy, fast and overall clean process.Our [Auto Single Head BUF Filler] (PFM-3BUF-A) is one of the more popular of our bottom up filling range and extremely popular with our food, beverage and personal care partners.

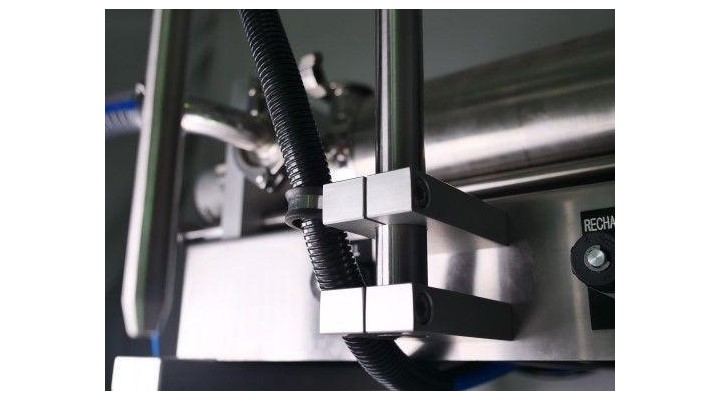

This versatile machine is a fully automatic filler and the valve system is more than capable of bottling everything from thin liquid, creams and thick paste and cream. It will even package products with soft suspended solids. Previously this task would have required 2 different types of filling machine or expensive change parts from other machine manufacturers. Manoeuvrability is not a challenge as this bottom up filling machine can be mounted on a trolley with lockable castors.

The auto single head BUF filler is perfect for any commercial in-house manufacturing operation. The filler is capable of filling 10-15 units per minute as a guide. The cylinder design of the PFM-3-BUF-A enables quicker dismantling and easier, more thorough cleaning of wet parts. Various product supply methods can be used according to the nature of product or customer preference e.g. close coupled hopper, suction hose inlet assembly, elevated or floor level tank, and low pressure feed from a pump.

We take great pride in the design and engineering efforts that goes into our suite of filling machines but what gives us a greater sense of contentment is knowing that we can provide a more complete solution beyond these machines. We would encourage all business owners to discover and become more informed before making a decision. That is what we are here for. So if you work in food, cosmetics, pharmaceuticals or chemical manufacturing and you need a versatile, compact and cost effective solution maybe it’s time to talk.