Do you want to keep noise and vibration to a minimum?

A lot of focus goes into reducing and containing noise and vibration within a vessel's engine room. In theory, those same fundamentals should be applied to your selection of driveshaft componentry.

Universal joints: Request a high spec joint that features thrust washer inserts in the bearing caps. By removing the clearance required between the bearing journal end and cap, these joints run cooler and quieter.

Rilson-coated slip splines: The fine tolerance combined with low friction properties of coated Euro series splines in marine shaft slip sections results in a very quiet, smooth running driveline, even at high operating speeds. With smooth, coated splines, maximum power can be transferred through the driveline rather than fighting against friction.

Another technical and safety benefit of the Rilson spline coating feature is electrical isolation between flanges. On the other hand, a standard, coarser 'metal-to-metal' spline assembly will need regular lubrication and checking for spline wear to keep noise and general operation at acceptable levels. Similar to gears, uncoated splines can also produce annoying 'chatter' at low rpms.

How much time do you have for maintenance?

Maintenance can be tedious at best. By specifying high performance 'lube-for-life' universal joints and sealed Rilson coated spline sections in your marine cardan shaft you'll be helping to provide a cleaner more user-friendly operating environment by eliminating the need for greasing.

The other upside is reduced maintenance costs due to the longer service intervals provided by these premium components.

How much space do you have?

It is not often there'll be an abundance of space left within a hull or engine/propulsion area to configure a bulky driveshaft. Any extra length or height required in your layout will encroach on available cabin or service area space.

Modern marine drivelines are predominantly manufactured from appropriately rated 'Euro' series componentry which provides the strength and performance needed for these applications while being very dimensionally compact.

For further space advantage, confirm that the driveline manufacturer can machine end flanges to suit the gearbox fixings eliminating the adaptor plate. Engines are often positioned to balance out the weight of other plant and equipment, so in some instances a longer series shaft may be needed with support bearings fitted at midpoint.

In shaft drive vessels, incorporating a thrust bearing unit in the driveline configuration can allow for a horizontal engine position, which is ideal for better space utilisation as well as ease of installation and alignment. (See section and figures to follow on thrust bearing applications.)

How important are thrust bearings?

By combining thrust bearings with a marine Cardan or CV shaft you get the perfect solution for conventional shaft drive vessels, reducing noise and vibration and simplifying engine installation and shaft alignment. Thrust force is absorbed through rubber pads parallel to the propeller shaft.

Rubber performs better under compression and by incorporating these units in the design softer engine mount material can be used, further enhancing the reduction of noise and vibration. Without the absorption of thrust at the propeller end of the driveline you risk the transfer of thrust and shock to the gearbox, which can be costly to repair if damage occurs.

Attachment and fixing of these thrust bearing units is simple with an internal clamp design for shafts up to 2.5", and larger bearings have standard flange bolting patterns.

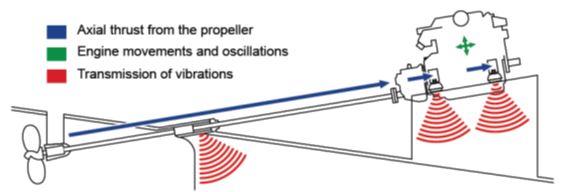

Without thrust bearings:

In traditional installations, the alignment of the propeller shaft to the engine has to be precise and subject to periodical maintenance. Stiff mounts transmit high levels of vibration to the hull, even when perfectly aligned.

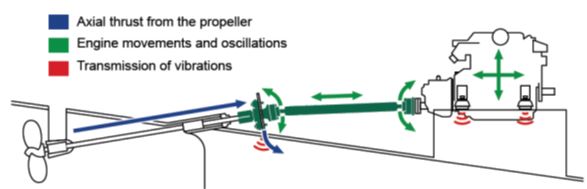

With thrust bearings:

With thrust bearings the engine can be installed in a horizontal position using soft and efficient mounts. Apart from easy installation and permanent alignment, this also leads to better space utilisation while dramatically reducing vibration and noise.

Do you comply with Lloyd’s Register survey standards?

Certain vessels require propulsion and drivetrain components to meet or exceed Lloyd's Register survey standards. Always ensure that you are dealing with manufacturers who are competent in producing marine shafts in compliance with these rigorous standards.

There is a thorough documented procedure and audit trail required involving crack and material testing on componentry and welding to be carried out to ISO15614 weld standards.