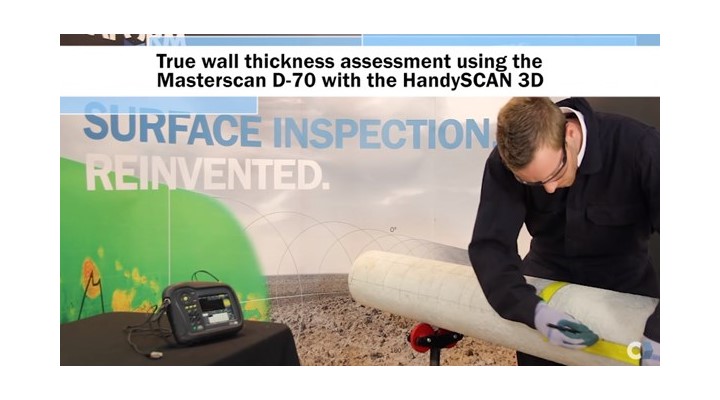

NDT inspectors can now produce more reliable and efficient pipeline evaluations than ever before by combining Ultrasonic Thickness (UT) measurements with 3D scan data. Most UT systems including Sonatest’s Masterscan D70, Veo+ or even conventional thickness gauges can now be combined with 3D scans from Creaform’s HandySCAN 3D scanner by using Pipecheck pipeline integrity assessment software. Perform safer pipeline integrity assessments with Sonatest and Creaform.

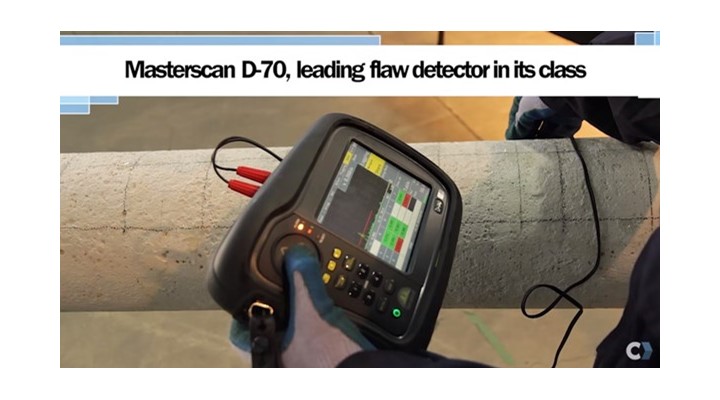

The Masterscan D-70 is the leading flaw detector in its class. This instrument offers a fully capable and functional set of tools and software for inspection across all applications. Capabilities include encoded B-Scan, Advanced Thickness logging and Dryscan capability in a portable and field upgradeable enclosure.

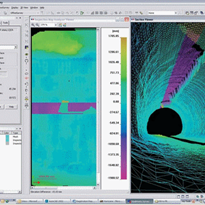

Using the UTility Lite software provided, inspectors have the tools readily available to manage inspection data as well as creating files for use in other applications such as Pipecheck .

The new Sonatest Veo+ is a Phased Array Digital Flaw Detector, which, when combined with a suitable probe such as the Sonatest WP2 Wheelprobe, can produce a high resolution C-Scan, allowing for increased analysis of the inner surface of the pipe. Using UTStudio software provided with the Veo+ scan data can be easily exported for reporting, or into a format that can be easily combined with 3D scan data.

By utilising Creaform’s Handyscan700 3D Scanner, a complete 3D surface map of the pipe is scanned directly into the Pipecheck software. True wall thickness assessment can then be made as Pipecheck combines the Masterscan UT data, or Veo C-Scan data with the 3D surface scan data for a reliable visualization and an optimal understanding of the pipeline’s anomalies.

By combining the results of the best NDT equipment for assessing both the inside and the outside lining of a pipeline, Pipecheck takes into account the interaction of the internal and external deterioration to calculate pipeline burst pressures. Pipecheck can also be used with the UT data only to provided burst pressure calculations quickly and easily without the inclusion of 3D scan data.

(1)-205x205.jpg)