REDUCE STRESS AND STRAIN OF HEAVY TOOLS

- Makes hard tasks easy; more uptime

- Less wear and tear on workers; fewer injuries

- Increase morale

- Improves craftsmanship

- Makes hard tasks easy; more uptime

- Less wear and tear on workers; fewer injuries

- Increase morale

- Improves craftsmanship

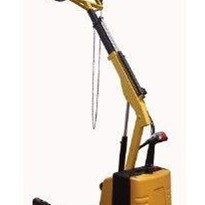

The MITS Zero G Workshop Trolley System enable workers to use heavy tool like impact wrenches, nut runners, grinders and chipping hammers effortlessly and as if weightless.With a working tool payload of up to 36kg, the MITS - Zero G Workshop System can be adapted for use with most heavy hand tools used in mining and heaving engineering workshops. The entry model MITS - Zero G workshop system is supplied complete with a compact mobile trolley, patented balancing system arm, and "Pigtail" Tool Arm and Lanyards.

Utilising spring tension and innovative design to balance the weight of tools used in bolt tensioning, drilling, sanding, riveting and many other applications the MITS- Zero G workshop system is fast becoming the latest technology to improve safety, efficiency and quality in heavy industry. Capable of holding tools weighing up to 36kg fully balanced allowing the user to freely, safely and accurately to lift aheavy tool in any direction without injury or fatigue.

THE MITS - ZERO G SYSTEM SPECIFICATION

Item code: ZG-SYS-WST-36

- Working tool payload up to 36kg

- Tool functioning operating arc 0-1400mm vertical and 2600mm horizontal range.

- Zero G single link balancing arm

- Zero G 300mm Link Arm Extension with Locking Pin

- Quick connection mounting ZeroG Fixed Axis Mounting Block with Locking Pin Gravity Docking Assembly

- Mobile trolley incorporating 2.4 mtr mast height, winch operated tool height adjustment, counterweights and bench.

- Trolley overall foot print 1200mm wide x 1200mm long x 2400mm high.

-160x160-state_article-rel-cat.jpg)