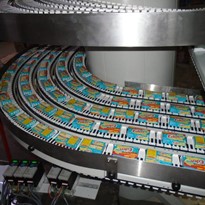

The cheese producer needed to connect their up-level processing area to the floor levels of the end of line environment.

Vacuum packed cheese blocks needed to be transported downwards at a rate of 40 per hour without damaging the plastic and losing any product lifetime. Having endless stainless steel guides without any sharp edges that could cut into your product packaging is a unique AmbaFlex feature. Because of the enormous de-elevation required, traditional conveyors were not an option. Platform elevators could also not be used because of their low throughput capacity.

A spiral conveyor was be the ideal solution for throughput and gentle product handling, but the challenge for a spiral conveyor was the minimum space that was available between the construction beams in the various floors. This was found to be too narrow for conventional spirals.

However the AmbaFlex SpiralVeyor® SVs platform, which was chosen, has a 140 mm wide belt and only requires a diameter of 1240mm, and fitted in. This machine comes from the Spiralveyor SlimLine programme and is especially designed with a small footprint to overcome space issues in packing areas.

The total elevation required 19.5 spiral windings and that is at the higher end of what is possible, even for AmbaFlex. Fortunately, the patented Triple-E conveyor belt technology with 100% rolling friction makes such a number of windings possible in one go with one belt.

The customer was very happy that AmbaFlex could fulfill all the requirements without any comprises such as the number of winding to de-elevate, the compact build required, the speed, and good product handling. And on top of all that, the solution comes with a full, stainless steel, welded frame which does not trap any dirt and contains no soft metals like aluminium – a must to handle the aggressive cleaning detergents used in the dairy industry.

One more proof of AmbaFlex’s leading position in Spiral Conveyor Solutions!